Manufacturing method of double-alloy double-structure titanium alloy blisk

A technology of an integral blisk and a manufacturing method, applied in the field of additive manufacturing, can solve the problems of tissue mutation, loosening at the joint, and reducing the service life of the integral blisk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

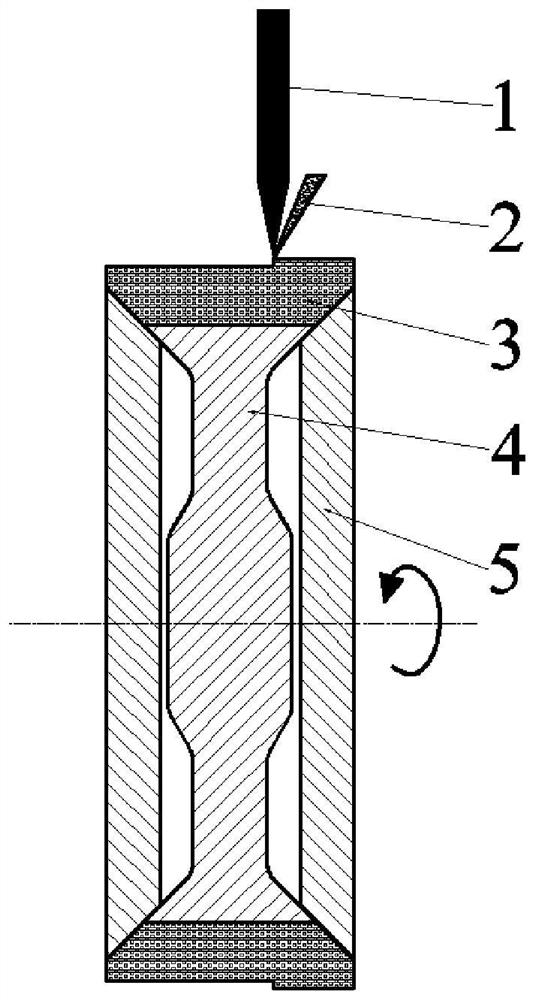

[0039] Step 1. Preparing the rough machining blank of the disc hub

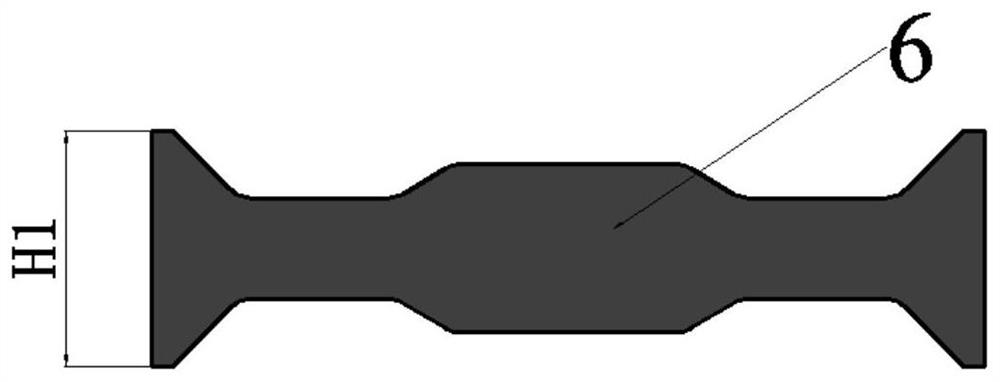

[0040] The phase transition point (T) of the Ti60 titanium alloy billet was measured by metallographic method β ) is 1055°C, the heating temperature of the forging die is set to 1055°C, the Ti60 titanium alloy billet is first preheated at 1030°C, and after 150 minutes of heat preservation, the temperature is rapidly raised to 1075°C for 50 minutes, and then the Ti60 titanium alloy billet is transferred to the heated The forging deformation is carried out in a mold with a forging speed of 0.7-1.0 mm / s and a deformation amount of 70%. After forging and deformation, the water cooling treatment is carried out quickly to prepare a disc hub forging blank 6 with a fine-grained mesh basket structure. The disc hub forging blank 6 is Dumbbell-shaped disc shape, the thickness H1 of the boss edge is 100mm;

[0041] Stress-relief annealing is carried out on the disk hub forging billet 6 by adopting a heat treatment syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com