Heat treatment technology for strengthening crystal boundary of cold rolling state ferronickel-based high temperature alloy

A high-temperature alloy, nickel-iron-based technology, applied in the field of high-temperature alloy materials for power stations, can solve the problems of intergranular fracture of alloys, affecting the high-temperature durability of alloy materials, etc., to achieve high-temperature durability, increase microhardness, and large grain size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

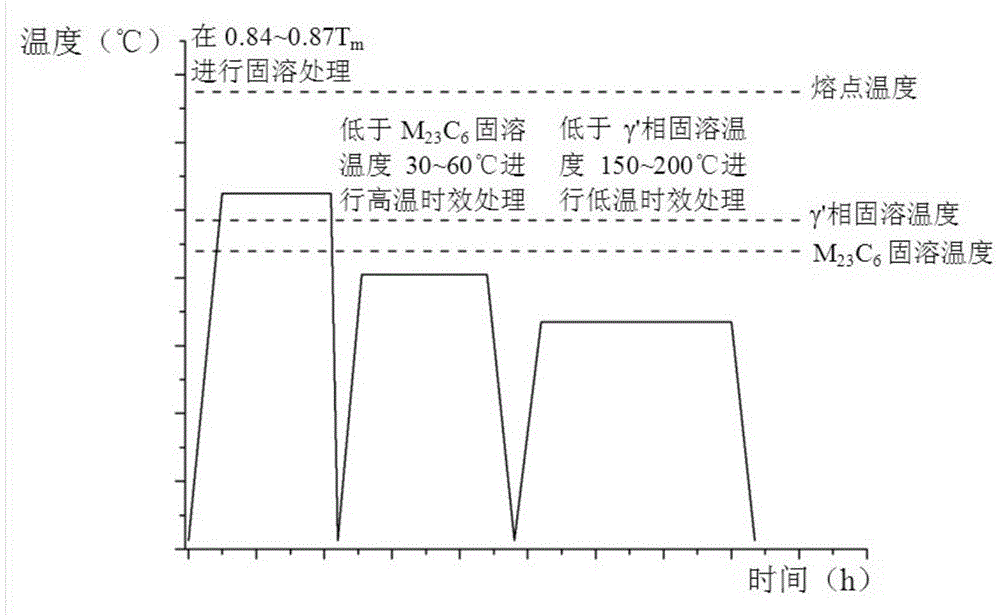

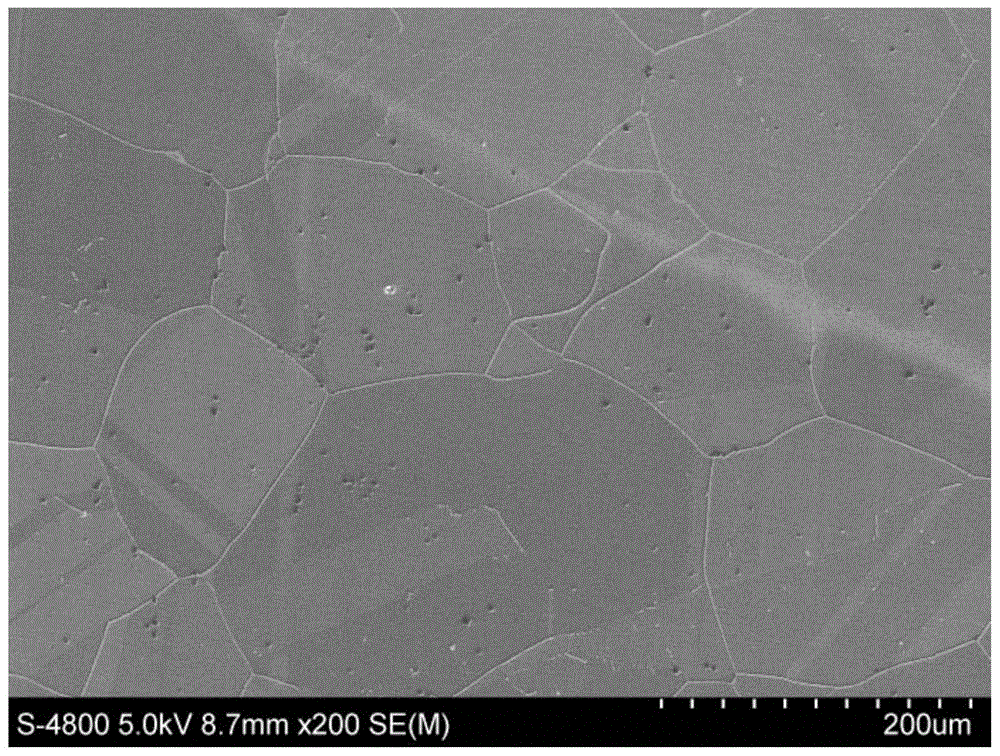

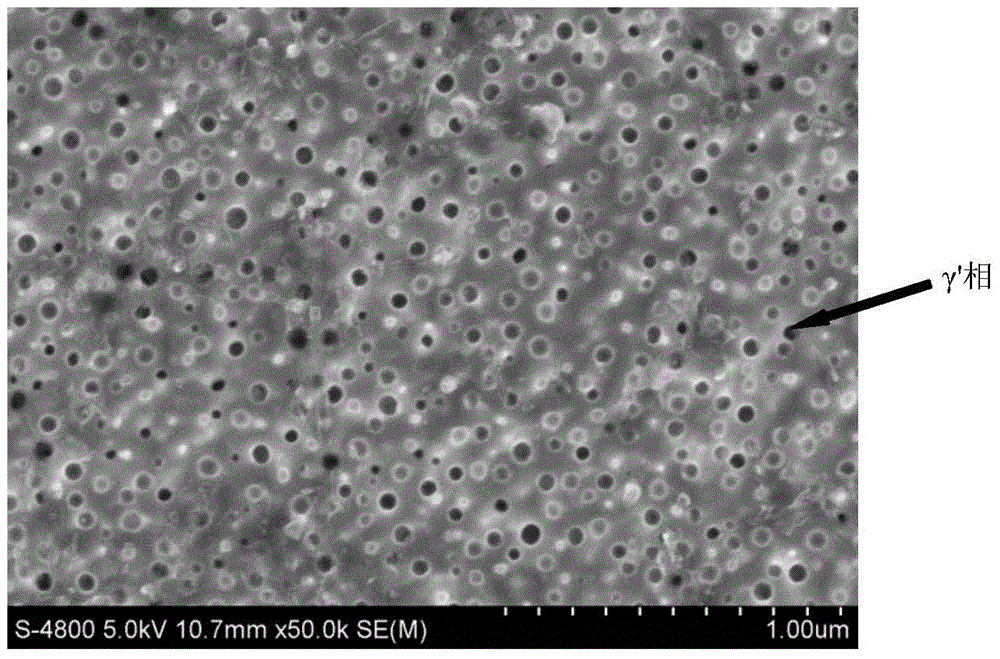

[0025] see figure 1 , take a nickel-iron-based superalloy within the composition range in the summary of the invention, the melting point of the alloy is 1400°C (1673K), the solid solution temperature of the γ' phase is 934°C, M 23 C 6 The solid solution temperature of type carbide is 855°C. The nickel-iron-based superalloy plate is rolled from 20mm to 10mm at room temperature, and then the first step of solution treatment is carried out. The alloy sample is kept at 1150°C for 1 hour and then air-cooled to room temperature; the second step is high temperature For aging treatment, the alloy sample was kept at 820°C for 1 hour and then air-cooled to room temperature; the third step was low-temperature aging treatment, and the alloy sample was kept at 780°C for 16 hours and then air-cooled to room temperature. The grain size of the alloy structure after heat treatment is 113 microns, the average size of the γ' phase is 55 nanometers, and the grain boundaries are continuous and ...

Embodiment 2

[0027] see figure 1 , take a nickel-iron-based superalloy within the composition range in the summary of the invention, the melting point of the alloy is 1392°C (1665K), the solid solution temperature of the γ' phase is 956°C, M 23 C 6 The solid solution temperature of carbide is 839°C. The nickel-iron-based superalloy plate is rolled from 20mm to 10mm at room temperature, and then the first step of solution treatment is carried out. The alloy sample is kept at 1150°C for 0.75 hours and then air-cooled to room temperature; the second step is high temperature For aging treatment, the alloy sample was kept at 810°C for 1 hour and then air-cooled to room temperature; the third step was low-temperature aging treatment, and the alloy sample was kept at 770°C for 12 hours and then air-cooled to room temperature. The grain size of the alloy structure after heat treatment is 120 microns, the average size of the γ' phase is 60 nanometers, and the grain boundaries are continuous and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com