Heat treatment method for stainless steel heat-resistant steel forging

A heat treatment method and technology of heat-resistant steel, applied in the field of metal heat treatment, can solve the problem that the high-temperature durability does not reach the specified value, and achieve the effect of improving the high-temperature durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In the annealing step, the heat-resistant stainless steel forging is heated to 900° C. at a rate of 30-35° C. / h and kept for 7 hours, then cooled to 450° C. in the furnace and then air-cooled.

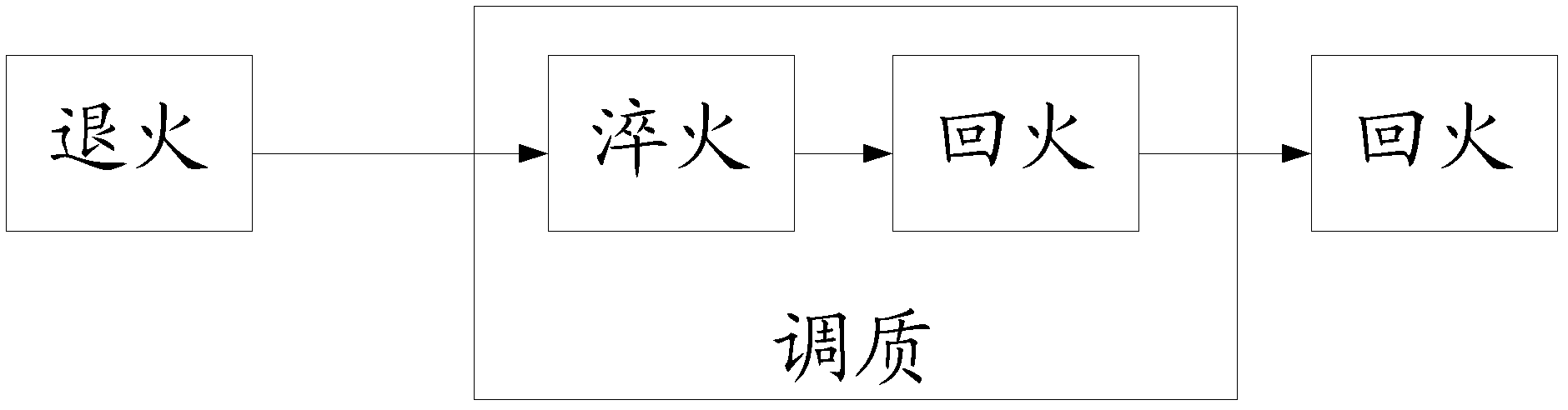

[0052] The quenching and tempering treatment includes a quenching process and a tempering process.

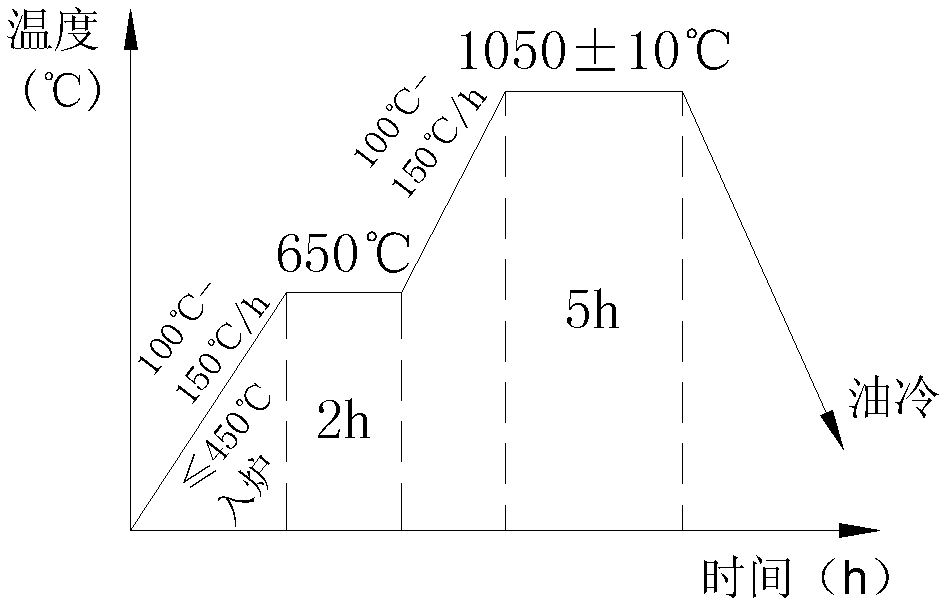

[0053] Described quenching process is as follows:

[0054] Put the heat-resistant stainless steel forging into the furnace at a temperature of 200°C;

[0055] Heat to 650°C at a rate of 100-105°C / h and hold for 2.5 hours;

[0056] Heating to 1080°C at a rate of 100-105°C / h and holding for 6.5 hours;

[0057] Oil cooling until the surface temperature of the stainless steel heat-resistant steel forging is 150-155 °C.

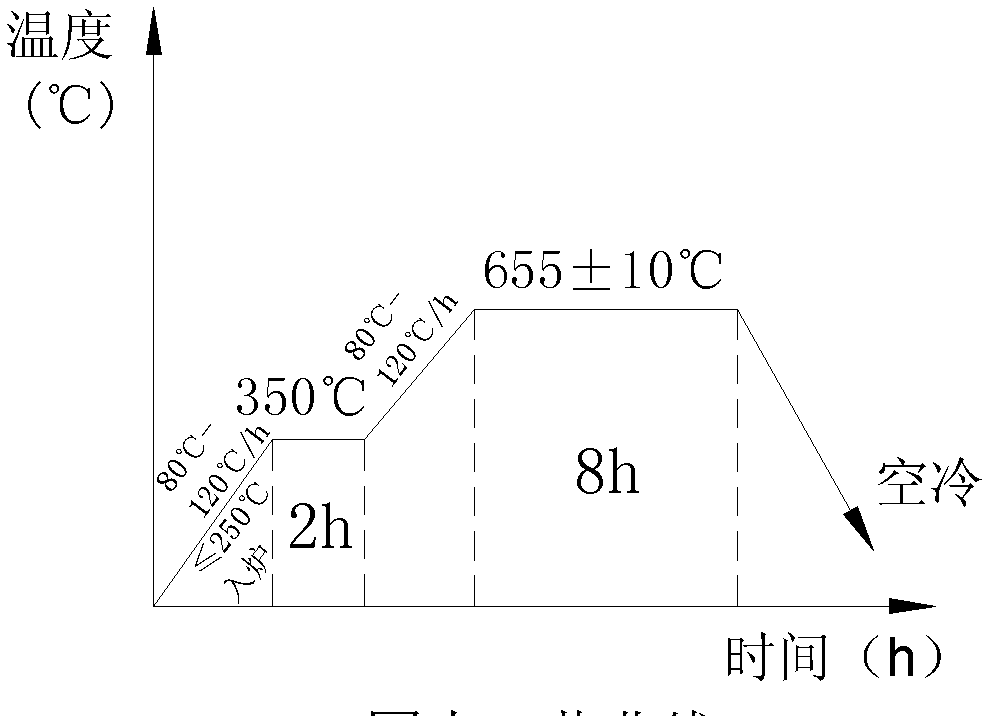

[0058] Described tempering process is as follows:

[0059] Put the stainless steel heat-resistant steel forging into the furnace at a temperature of 250°C;

[0060] Heating to 320°C at a rate of 80-85°C / h and holding for 2.5 hours;

[0061] Heating to 645°C at ...

Embodiment 2

[0064] In the annealing step, the heat-resistant stainless steel forging is heated to 920° C. at a rate of 45-50° C. / h and kept at a temperature of 8 hours, then cooled to 500° C. with the furnace and then air-cooled after being released from the furnace.

[0065] The quenching and tempering treatment includes a quenching process and a tempering process.

[0066] Described quenching process is as follows:

[0067] Put the stainless steel heat-resistant steel forging into the furnace at a temperature of 450°C;

[0068] Heating to 680°C at a rate of 125-130°C / h and holding for 3 hours;

[0069] Heating to 1090°C at a rate of 125-130°C / h and holding for 6 hours;

[0070] Oil cooling until the surface temperature of the stainless steel heat-resistant steel forging is 165-170°C.

[0071] Described tempering process is as follows:

[0072] Put the stainless steel heat-resistant steel forging into the furnace at a temperature of 250°C;

[0073] Heating to 350°C at a rate of 100-10...

Embodiment 3

[0082] In the annealing step, the heat-resistant stainless steel forging is heated to 940° C. at a rate of 70-80° C. / h and kept for 9 hours, then cooled to 550° C. in the furnace and then air-cooled.

[0083] The quenching and tempering treatment includes a quenching process and a tempering process.

[0084] Described quenching process is as follows:

[0085] Put the stainless steel heat-resistant steel forging into the furnace at a temperature of 400°C;

[0086] Heating to 700°C at a rate of 145-150°C / h and holding for 3.5 hours;

[0087] Heating to 1100°C at a rate of 145-150°C / h and holding for 5.5 hours;

[0088] Oil cooling until the surface temperature of the stainless steel heat-resistant steel forging is 195-200°C.

[0089] Described tempering process is as follows:

[0090] Put the heat-resistant stainless steel forging into the furnace at a temperature of 150°C;

[0091] Heating to 380°C at a rate of 110-120°C / h and holding for 3.5 hours;

[0092] Heating to 66...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com