Al-Si-Cu-Mn heat-resistant aluminum alloy with high Fe content and preparation method thereof

A technology of al-si-cu-mn and al-si-cu-mn-ti, applied in the field of metal materials, can solve the problems of secondary pollution, time-consuming and laborious disinfection, poor disinfection effect, etc. The effect of simple element composition and high temperature strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

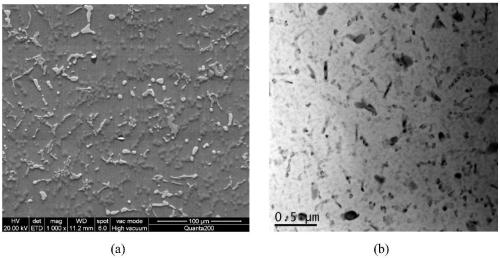

Image

Examples

Embodiment 1

[0017] Example 1: An Al-Si-Cu-Mn-Ti heat-resistant aluminum alloy with a high Fe content, with a total mass of 4kg, including the following components and their mass percentages: Cu: 6.0%, Mn: 0.4%, Fe : 0.1%, Si: 7.0%, Ti: 0.1%, and the balance is Al and unavoidable impurities. The preparation method of the heat-resistant aluminum alloy includes the following steps:

[0018] (1) Smelting: According to the alloy composition of the ratio, add aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-iron master alloy, aluminum-silicon master alloy, aluminum-titanium master alloy and pure aluminum, and more than 2 / 3 of the furnace charge is melted, and the furnace charge is After all melting, lower the furnace temperature to 720°C and keep it for 20 minutes; after the furnace temperature is stable, remove the slag, add argon for refining, keep it at 725°C for 15 minutes, and then skim the slag to obtain a refined metal melt;

[0019] (2) Casting: Preheat the castin...

Embodiment 2

[0023] Example 2: An Al-Si-Cu-Mn-Ti heat-resistant aluminum alloy with a high Fe content, with a total mass of 4kg, including the following components and their mass percentages: Cu: 8.0%, Mn: 1.2%, Fe : 1.0%, Si: 9.0%, Ti: 1.0%, and the balance is Al and unavoidable impurities. The preparation method of the heat-resistant aluminum alloy comprises the following steps:

[0024] (1) Melting: Add aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-iron master alloy, aluminum-silicon master alloy and pure aluminum according to the alloy composition, and melt more than 2 / 3 of the charge. After all the charge is melted, put The furnace temperature is lowered to 730°C and kept for 15 minutes; after the furnace temperature is stable, remove the slag, add argon gas for refining, keep at 730°C for 10 minutes, and skim the slag to obtain a refined metal melt;

[0025] (2) Casting: preheat the casting mold to 220°C, and pour the refined metal melt into billets;

[002...

Embodiment 3

[0029] Example 3: An Al-Si-Cu-Mn-Ti heat-resistant aluminum alloy with a high Fe content, with a total mass of 4kg, including the following components and their mass percentages: Cu: 7%, Mn: 0.8%, Fe : 0.45%, Si: 8.0%, Ti: 0.45%, and the balance is Al and unavoidable impurities. The preparation method of the heat-resistant aluminum alloy comprises the following steps:

[0030] (1) Melting: Add aluminum-copper master alloy, aluminum-manganese master alloy, aluminum-iron master alloy, aluminum-silicon master alloy and pure aluminum according to the alloy composition, and melt more than 2 / 3 of the charge. After all the charge is melted, put The furnace temperature is lowered to 725°C and kept for 17 minutes; after the furnace temperature is stable, the slag is removed, and after adding argon for refining, the slag is skimmed after being kept at 728°C for 17 minutes to obtain a refined metal melt;

[0031] (2) Casting: Preheat the casting mold to 260°C, and pour the refined metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com