Thermal treatment method for obtaining nanometer strengthening phase by HR3C austenitic heat-resistance steel

A technology of austenitic heat-resistant steel and heat treatment method, applied in the field of heat treatment, can solve the problem of difficulty in obtaining high-density nano-strengthening, and achieve the effects of good high-temperature strengthening effect, good high-temperature corrosion resistance and high thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

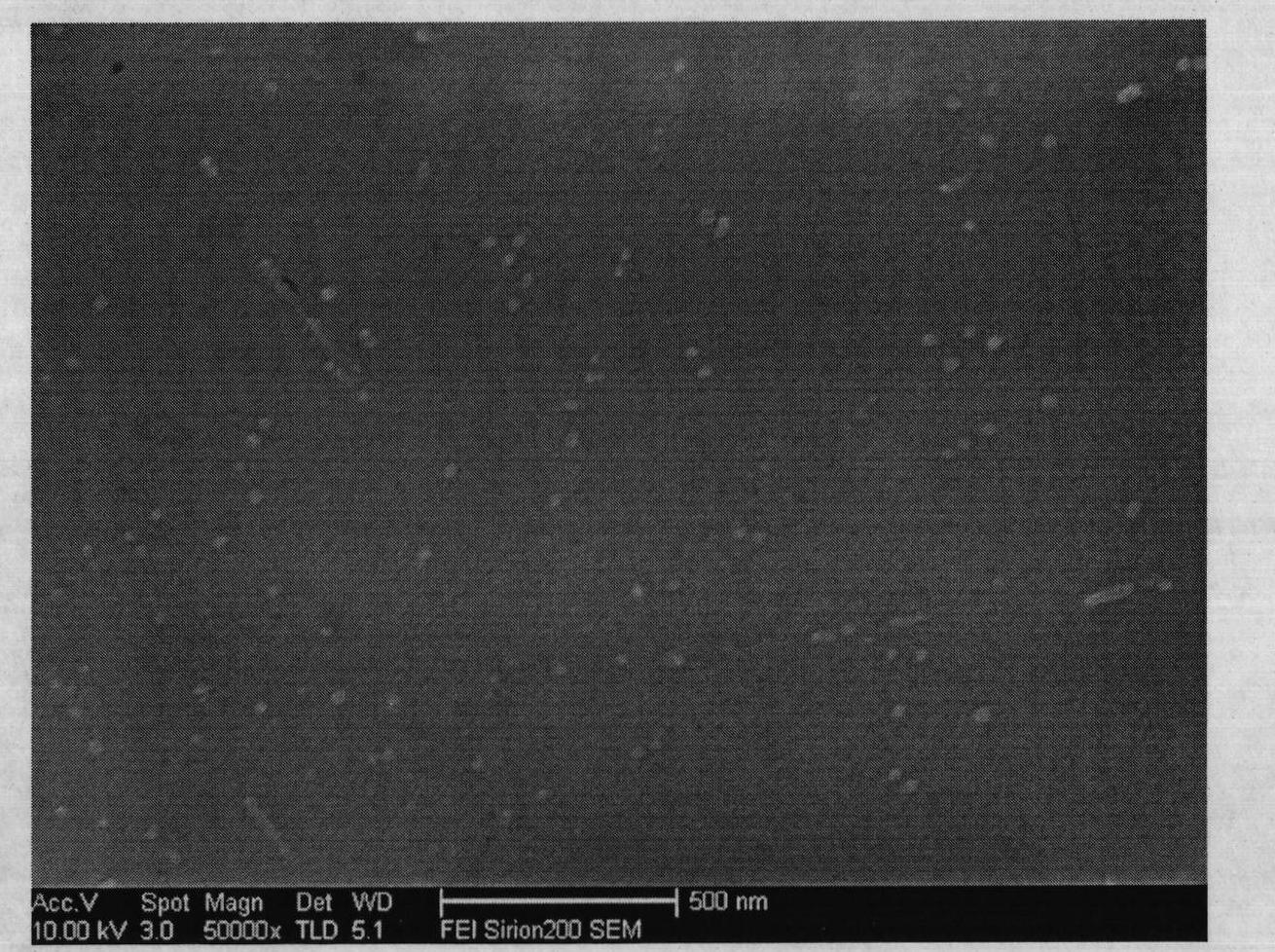

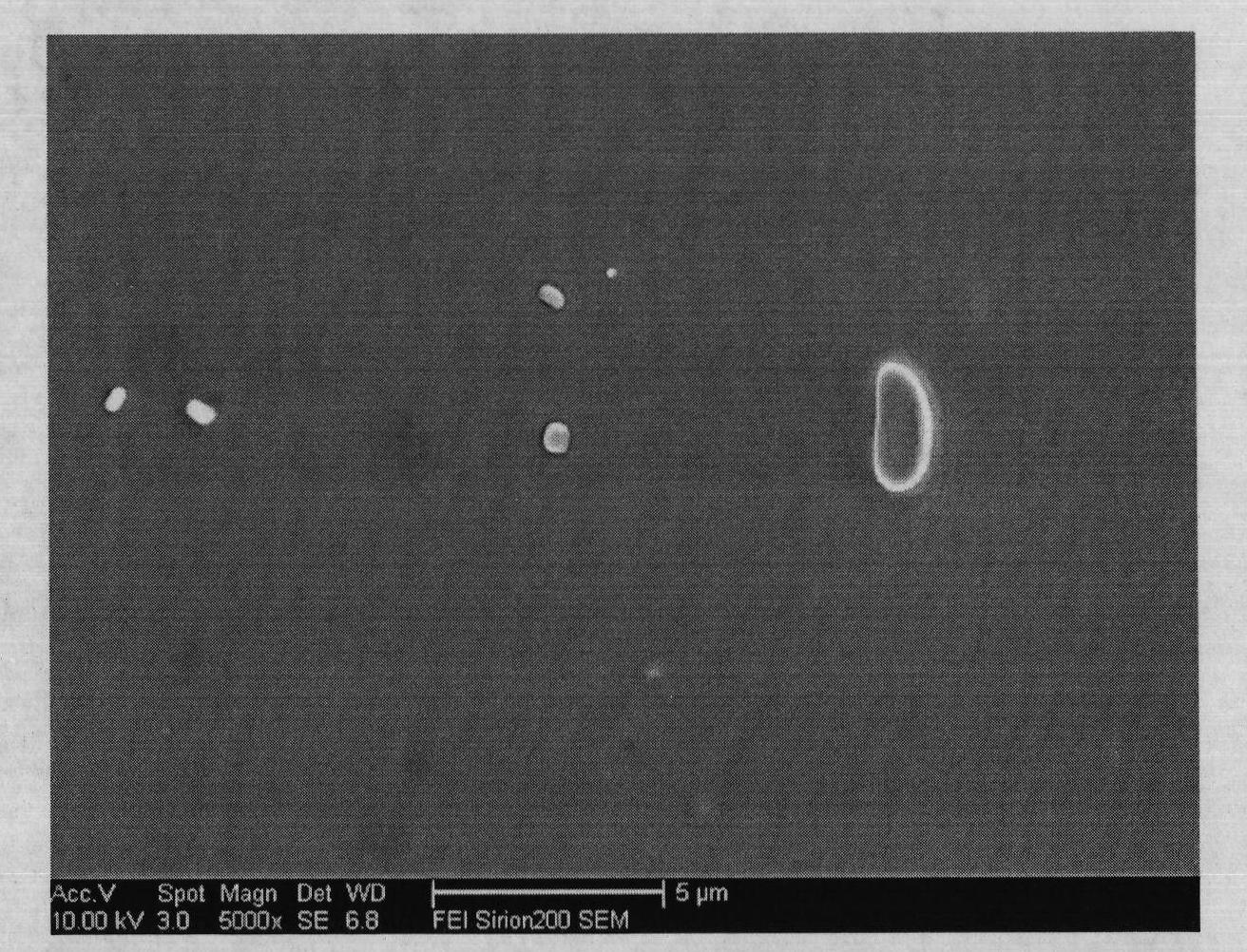

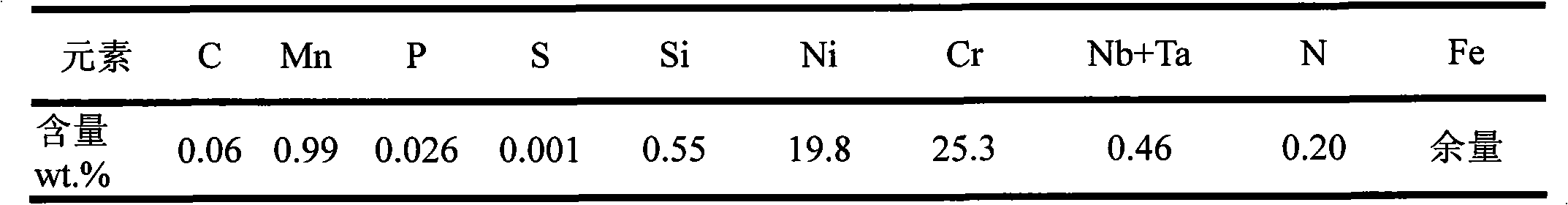

[0012] The chemical composition of HR3C austenitic heat-resistant steel used in the test is shown in Table 1. The HR3C steel piece is obtained through smelting, thermal processing and cold processing, and then heat treated according to the heat treatment method of the present invention, and the heat treatment process parameters are shown in Table 2. Part of the heat-treated HR3C steel piece is processed into a metallographic sample, and the morphology of the strengthening phase is observed under the FEI Sirion scanning electron microscope, and the number of nano-reinforcement phase particles contained in each square micron area is measured, and part of it is processed into a standard durable sample Endurance tests were carried out on the CSS-3905 electronic creep endurance tester. According to the enduring test results, the enduring strength at 700°C and 100,000 hours was estimated by the Larson-Miller parameter method. Table 2 lists the number of particles of the nano-reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com