Heat treatment method for improving high-temperature endurance property of GH2132 bolt

A technology of GH2132 and heat treatment method, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems that GH2132 bolt grain size, durability performance, and fatigue life cannot be guaranteed at the same time, so as to ensure fatigue performance and use safety, high temperature The effect of long-lasting performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

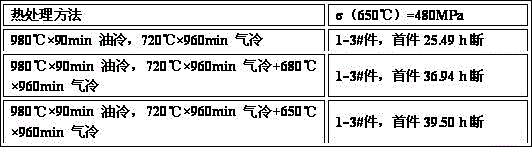

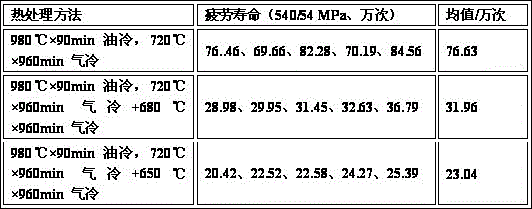

[0022] The heat treatment method used in this example includes a solid solution process and two aging processes. During the specific implementation, the bolts formed by heading the head are cleaned and dried, and a double-chamber vacuum oil quenching furnace is used for solid solution. When the furnace is installed, the product is evenly spread on the oil quenching furnace tooling in a single layer, and the furnace is heated at 650°C. , heating up for 35 minutes, the heating temperature is 980°C, and the heat preservation is 90 minutes. During the heat preservation period, the vacuum degree is controlled within the range of 1.3-13Pa. After the heat preservation is over, it will be automatically released for oil cooling. Then the solid-solution bolts are cleaned and dried, and the first aging process is carried out in a single-chamber vacuum air quenching furnace. When the furnace is loaded, the product is evenly placed on the aging tooling in a single layer, put into the fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com