High-strength rare earth doped alloy material with high-temperature oxidation resistance and preparation method

A technology of high temperature oxidation resistance and alloy materials, applied in the field of metal materials, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

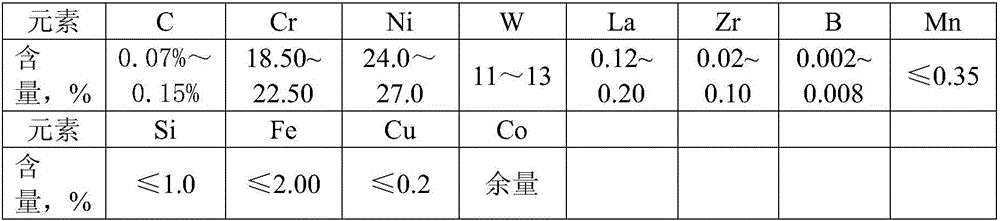

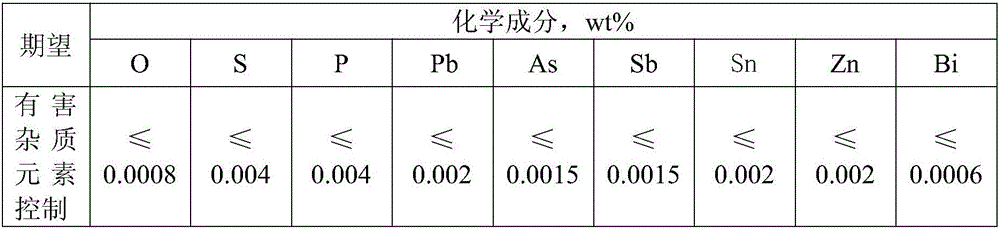

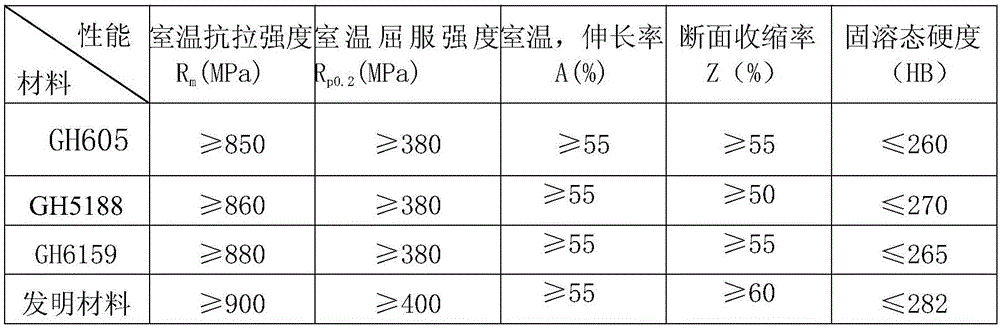

Method used

Image

Examples

Embodiment 1

[0064] According to the chemical composition (Wt%) C: 0.08, Ni: 24.5, Cr: 19.5, Zr: 0.02, B: 0.003, W: 11.5, La: 0.12, Co: balance, refined twice in a vacuum furnace, the temperature is 1525 ~ 1565°C, wherein, the first refining time is 10-20 minutes, the vacuum degree is 1-0.1Pa, the second refining time is 10 minutes, the vacuum degree is 0.1-0.002Pa, uniform pouring, and its uniform pouring is in a thin stream Fast pouring, the time is 12 to 18 seconds, to obtain remelted electrode rods;

[0065] The remelted electrode rod is remelted under the condition of filling helium in vacuum, the vacuum degree is ≤6.5Pa, the current is 2500-3000A, and the alloy ingot is obtained, and the homogenization heat treatment is carried out. For alloy ingots with a diameter larger than 200mm, according to the diameter of the alloy ingot, the total holding time is determined as 1.5min for 1mm holding time; for alloy ingots with a diameter of less than 200mm, the holding time is 5h, and the all...

Embodiment 2

[0069] According to chemical composition (Wt%) C: 0.10, Ni: 25.5, Cr: 20.5, Zr: 0.04, B: 0.004, W: 12.5, La: 0.15, Co: balance, all the other preparation methods are the same as in Example 1.

[0070] After subsequent processing, the belt for sealing sheet is applied to aero-engine turbines and sub-gas turbines. 900℃, high temperature oxidation rate 0.026g / (m 2 .h).

[0071] After testing: room temperature tensile strength R m is 955MPa, R p0.2 It is 485MPa. High temperature durable life and high temperature elongation 870°C, Rm: 115MPa, τ is 70h, A5 is 8%; 925°C, Rm: 70MPa, τ is 39h, A5 is 14%

Embodiment 3

[0073] According to chemical composition (Wt%) C: 0.11, Ni: 25.5, Cr: 21.0, Zr: 0.06, B: 0.005, W: 12.5, La: 0.18, Co: balance, all the other preparation methods are the same as in Example 1.

[0074] After subsequent processing into strips for corrugated pipes, it is used in aerospace and aerospace. 900℃, high temperature oxidation rate 0.023g / (m 2 .h).

[0075] After testing: room temperature tensile strength R m 969MPa, R p0.2 It is 486MPa. High temperature durability and elongation at 870°C, Rm: 115MPa, τ is 75h, A5 is 12%; 925°C, Rm: 70MPa, τ is 43h, A5 is 18%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Room temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com