Heat treatment method for super-alloy electromagnetic stirring roller used in high-temperature environment

A heat treatment method and electromagnetic stirring technology, which is applied in the field of heat treatment of superalloy electromagnetic stirring rollers for high temperature, can solve the problems of surface wear, short service life and fracture of electromagnetic stirring rollers, and achieve the purpose of increasing service life, improving service life, and high temperature long-lasting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

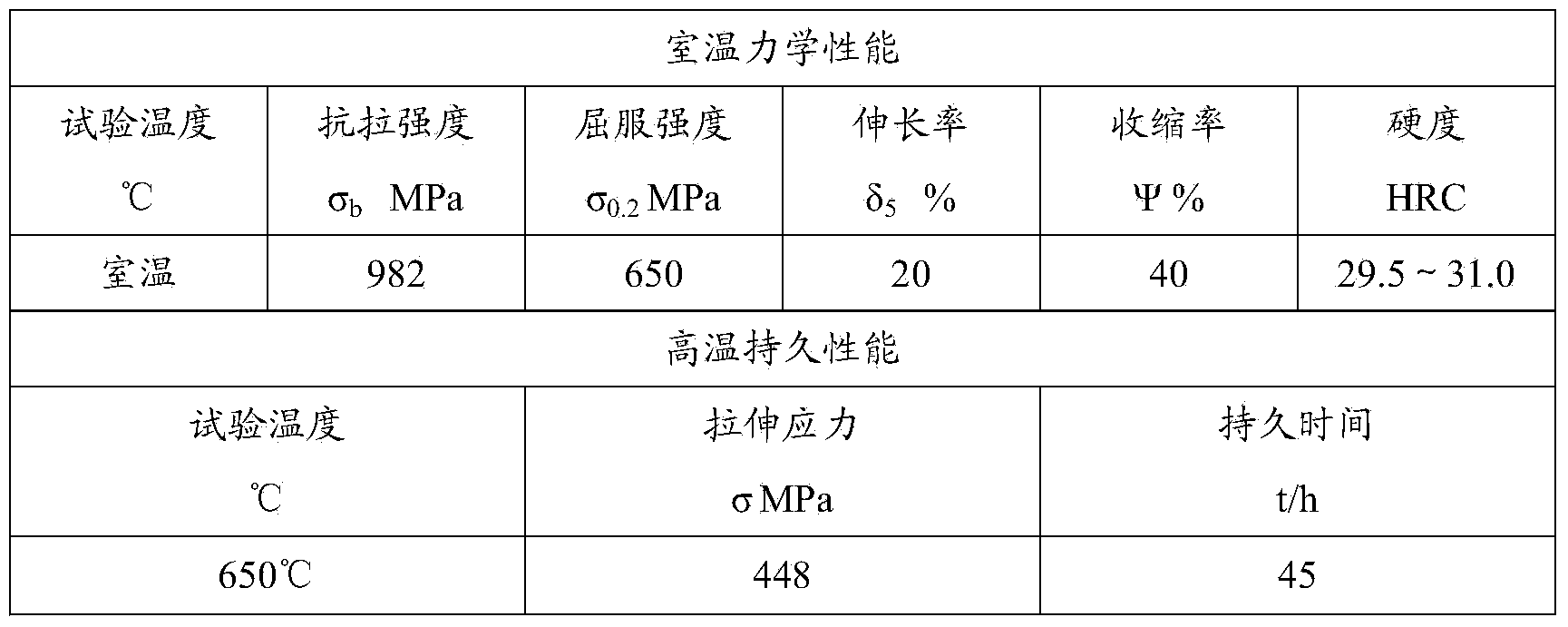

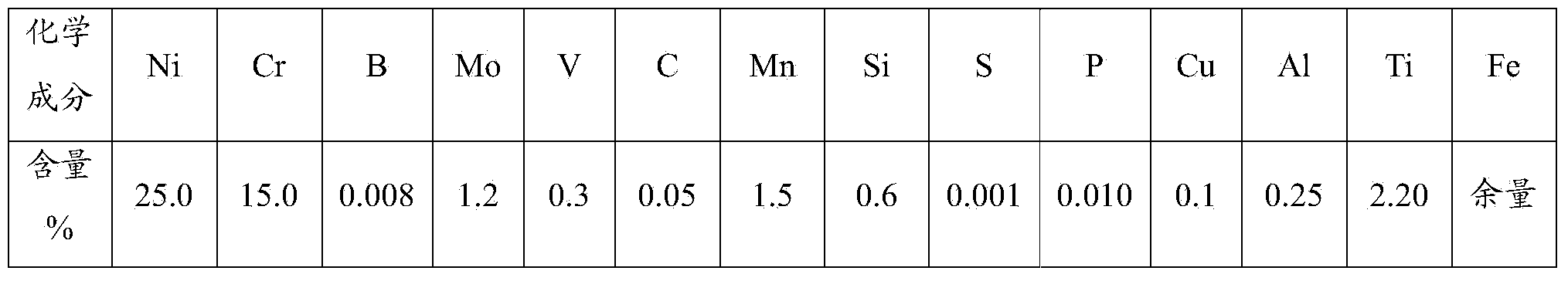

[0027] In the electromagnetic stirring roller made of superalloy UNS S66286 material, the chemical composition of UNS S66286 material and the weight percentage of each chemical composition are shown in Table 2:

[0028] Table 2 Unit: weight percentage

[0029]

[0030] The heat treatment method of the electromagnetic stirring roller made of the above UNS S66286 material is as follows:

[0031] The electromagnetic stirring roller made of superalloy UNS S66286 material is placed in the electric heating furnace. When placed in the electric heating furnace, the electromagnetic stirring roller made of UNSS66286 material is placed in the electric furnace of the full-fiber 5-sided heating trolley, and it is subjected to solution treatment and aging in turn. After the treatment and stabilization treatment, the high-temperature superalloy UNS S66286 electromagnetic stirring roll is obtained; wherein,

[0032] During the solid solution treatment, heat up to 450°C for 60 minutes, the...

Embodiment 2

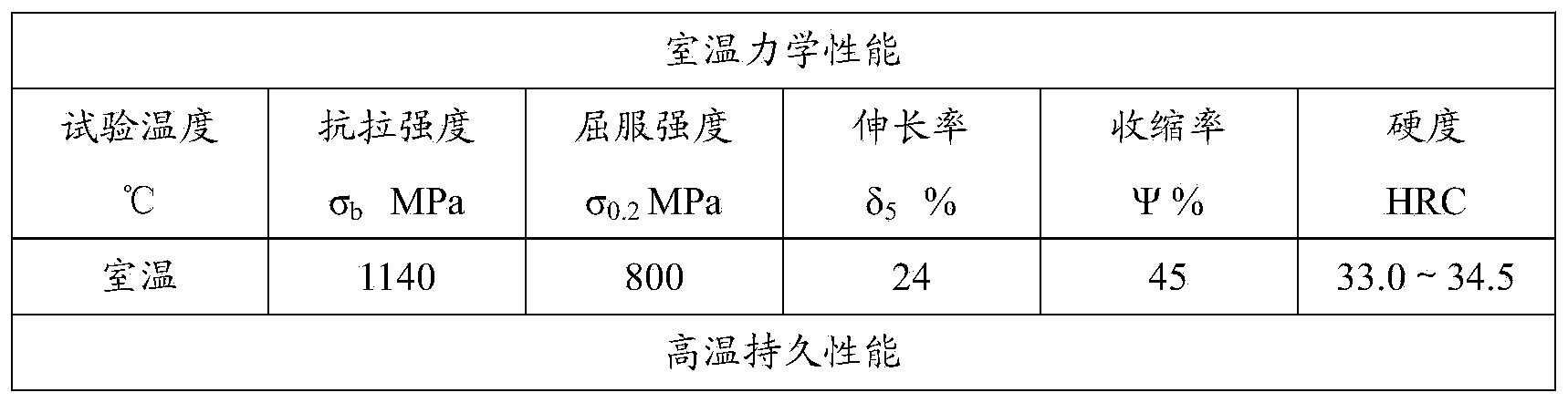

[0041] In the electromagnetic stirring roller made of superalloy UNS S66286 material, the chemical composition of UNS S66286 material and the weight percentage of each chemical composition are shown in Table 4:

[0042] Table 4 Unit: weight percentage

[0043]

[0044] The heat treatment method of the electromagnetic stirring roller made of the above UNS S66286 material is as follows:

[0045] The electromagnetic stirring roller made of superalloy UNS S66286 material is placed in the electric heating furnace. When placed in the electric heating furnace, the electromagnetic stirring roller made of UNSS66286 material is placed in the electric furnace of the full-fiber 5-sided heating trolley, and it is subjected to solution treatment and aging in turn. After the treatment and stabilization treatment, the high-temperature superalloy UNS S66286 electromagnetic stirring roll is obtained; wherein,

[0046] During the solution treatment, heat up to 440°C for 60 minutes, then heat...

Embodiment 3

[0054] In the electromagnetic stirring roller made of superalloy UNS S66286 material, the chemical composition of UNS S66286 material and the weight percentage of each chemical composition are shown in Table 6:

[0055] Table 6 Unit: weight percentage

[0056]

[0057] The heat treatment method of the electromagnetic stirring roller made of the above UNS S66286 material is as follows:

[0058] The electromagnetic stirring roller made of superalloy UNS S66286 material is placed in the electric heating furnace. When placed in the electric heating furnace, the electromagnetic stirring roller made of UNSS66286 material is placed in the electric furnace of the full-fiber 5-sided heating trolley, and it is subjected to solution treatment and aging in turn. After the treatment and stabilization treatment, the high-temperature superalloy UNS S66286 electromagnetic stirring roll is obtained; wherein,

[0059] During the solid solution treatment, heat up to 460°C for 60 minutes, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile stress | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com