Heatproof stainless steel seamless tube and production method thereof

A technology of heat-resistant stainless steel and seamless pipes, applied in the field of metallurgy, can solve problems such as insufficient high-temperature strength, easy coarsening, poor tissue stability, etc., and achieve good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

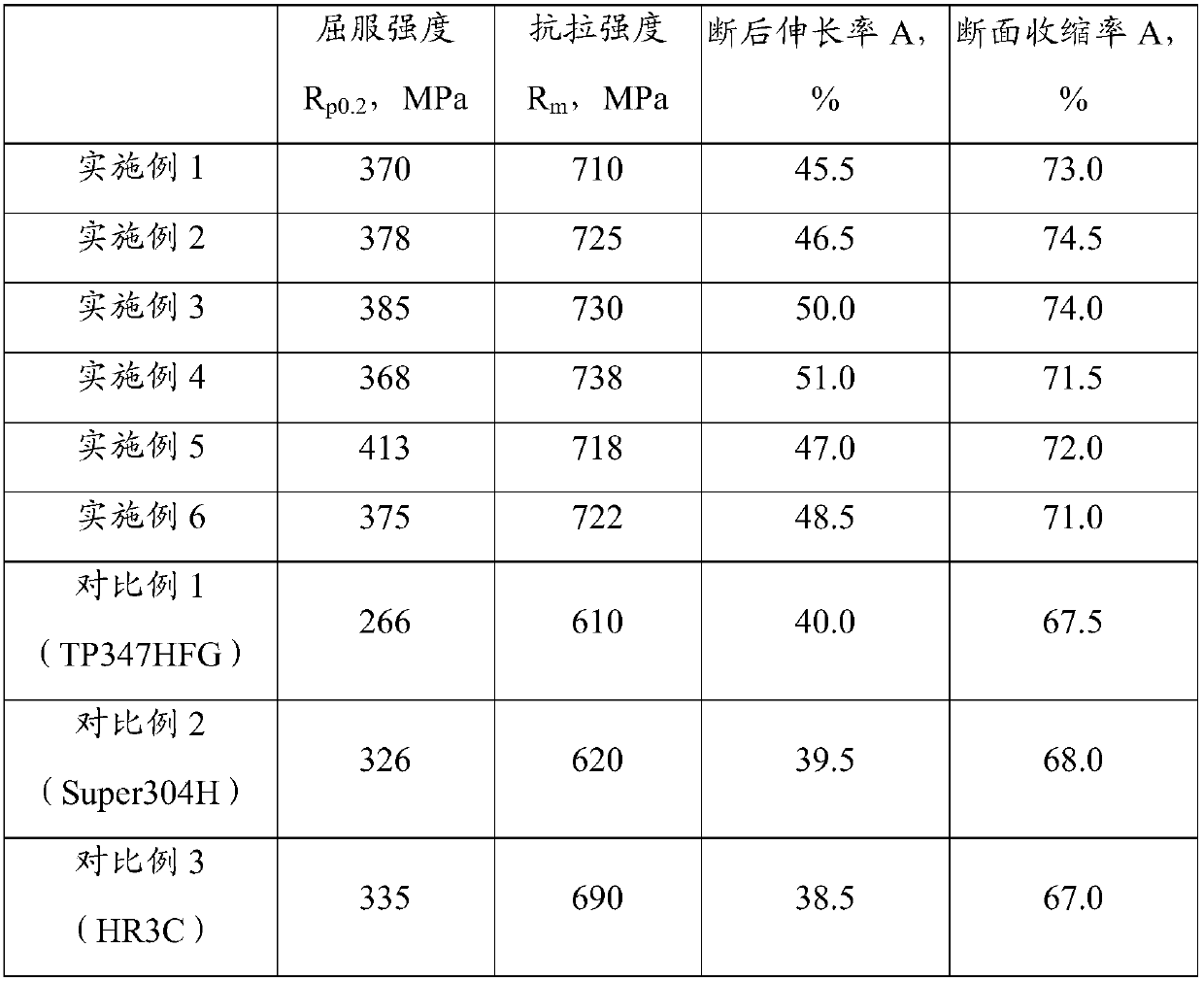

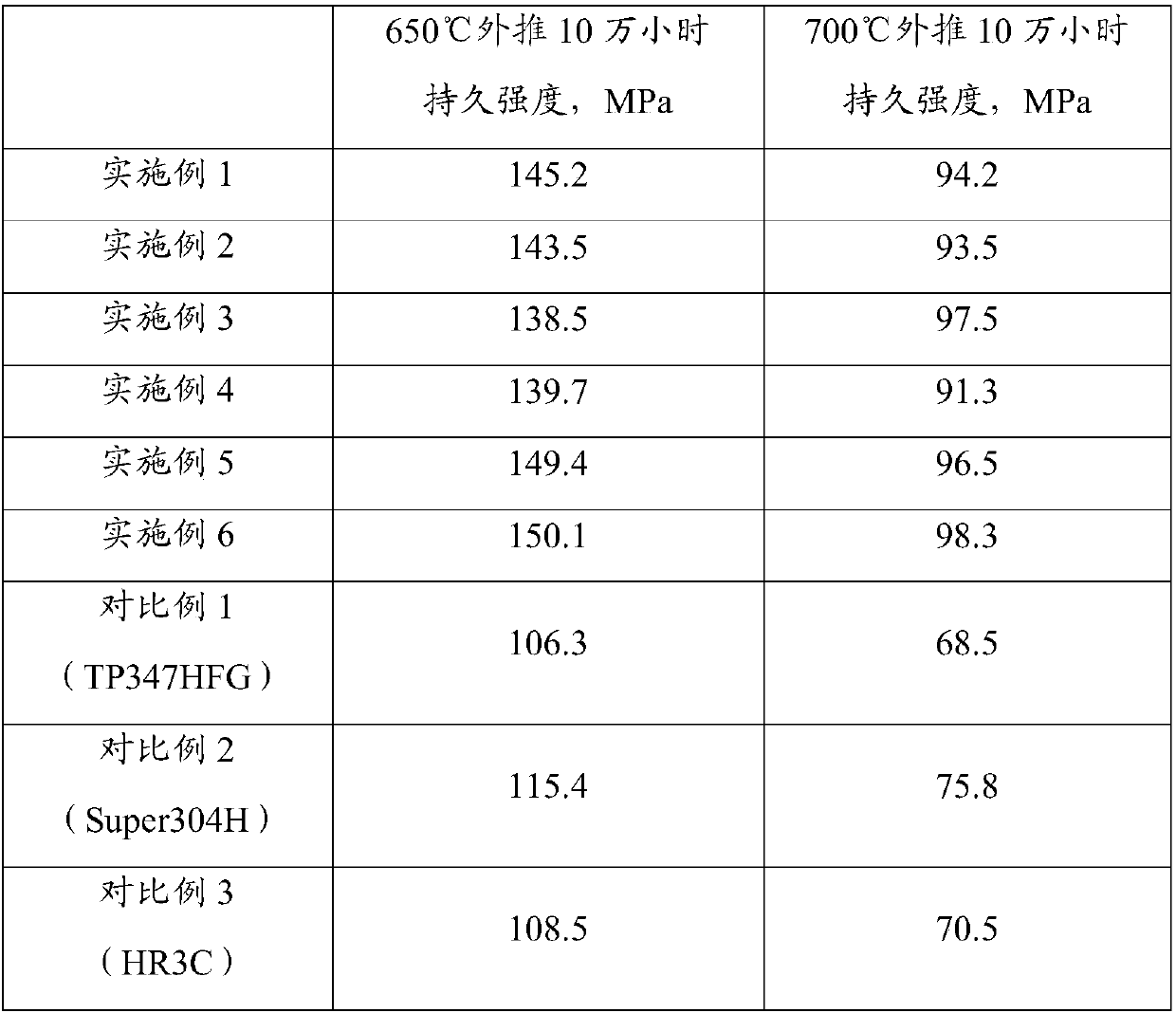

Examples

preparation example Construction

[0044] In the second aspect, the present invention provides a method for preparing a heat-resistant stainless steel seamless pipe, comprising: making a billet from an ingot to form a billet; performing thermal processing on the billet to obtain a capillary; refining the capillary whole, followed by cold working to obtain a blank pipe; heating the blank pipe and keeping it warm.

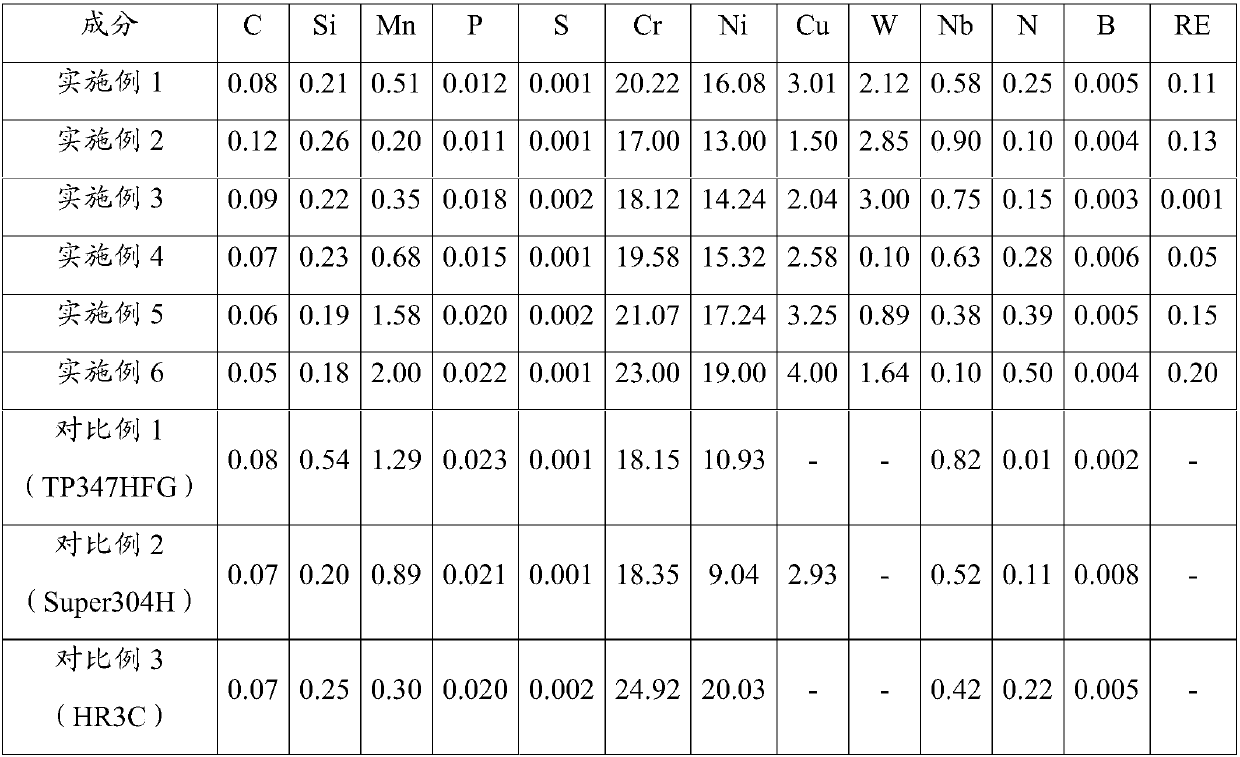

[0045] Preferably, the ingot is produced by the following method: the alloy material or steel scrap is melted in an electric furnace, and after decarburization in the AOD furnace and refining in the LF furnace, the molten steel can be tapped when the weight percentage of the molten steel reaches the following ratio: C0.05%~0.12 %, Si≤0.3%, Mn 0.2%~2%, P≤0.03%, S≤0.02%, Cr 17%~23%, Ni 13%~19%, Cu 1.5%~4%, W0.1%~ 3%, Nb 0.1%-0.9%, N 0.1%-0.5%, B 0.003%-0.006%, RE 0.001%-0.2%; then the molten steel is cast into an ingot.

[0046] Preferably, before the ingot is billeted to form a tube billet, the ingot ...

Embodiment 1

[0076] The composition of the stainless steel seamless pipe of Example 1 is shown in Table 1.

[0077] The preparation method of the stainless steel seamless pipe of embodiment 1 is:

[0078] The alloy material is melted in an electric furnace, and after AOD decarburization and LF refining, the ingot is cast by die casting. The red is sent to the soaking furnace for heating at 1120°C, the holding time is 1.2min / mm; the heating is at 100°C / h to 1200°C and the holding time is 1.0min / mm. The blank is opened by radial forging, the opening temperature is 1150°C, the final forging temperature is 950°C, the total deformation of forging is 75%, and the tube blank is manufactured.

[0079] Drill a 40mm centering hole in the center of the tube billet, preheat the ring furnace to 950°C, and heat it for 1.2min / mm, and heat it to 1150°C through an induction furnace when it comes out of the furnace. Glass powder, use a vertical punching machine to expand the hole, and the tube blank after...

Embodiment 2

[0081] The composition of the stainless steel seamless pipe of Example 2 is shown in Table 1.

[0082] The preparation method of the stainless steel seamless pipe of embodiment 2 is:

[0083] The alloy material is melted in an electric furnace, and after AOD decarburization+ and LF refining, the ingot is cast by continuous casting. The red is sent to a soaking furnace for heating at 1130°C, and the holding time is 1.1min / mm; it is heated at 110°C / h to 1200°C and held at 1.0min / mm. The billet is opened by hot rolling, the rolling temperature is 1120°C, the final rolling temperature is 920°C, and the total rolling deformation is 65%, and it is manufactured into a tube billet.

[0084] Directly heat the solid tube billet to 1120°C in an inclined bottom furnace, the heating time is 2.0min / mm, and use a bacteria-type piercer to perforate after being released from the furnace. The surface temperature before piercing is 1080°C, and the top is coated with glass powder for lubrication...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com