Materials for producing high pressure and low pressure joint rotor of steam turbine

A high-low pressure, steam turbine technology, applied in the field of materials for manufacturing steam turbine rotors, can solve problems such as the inability to meet the performance requirements of single-cylinder units

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

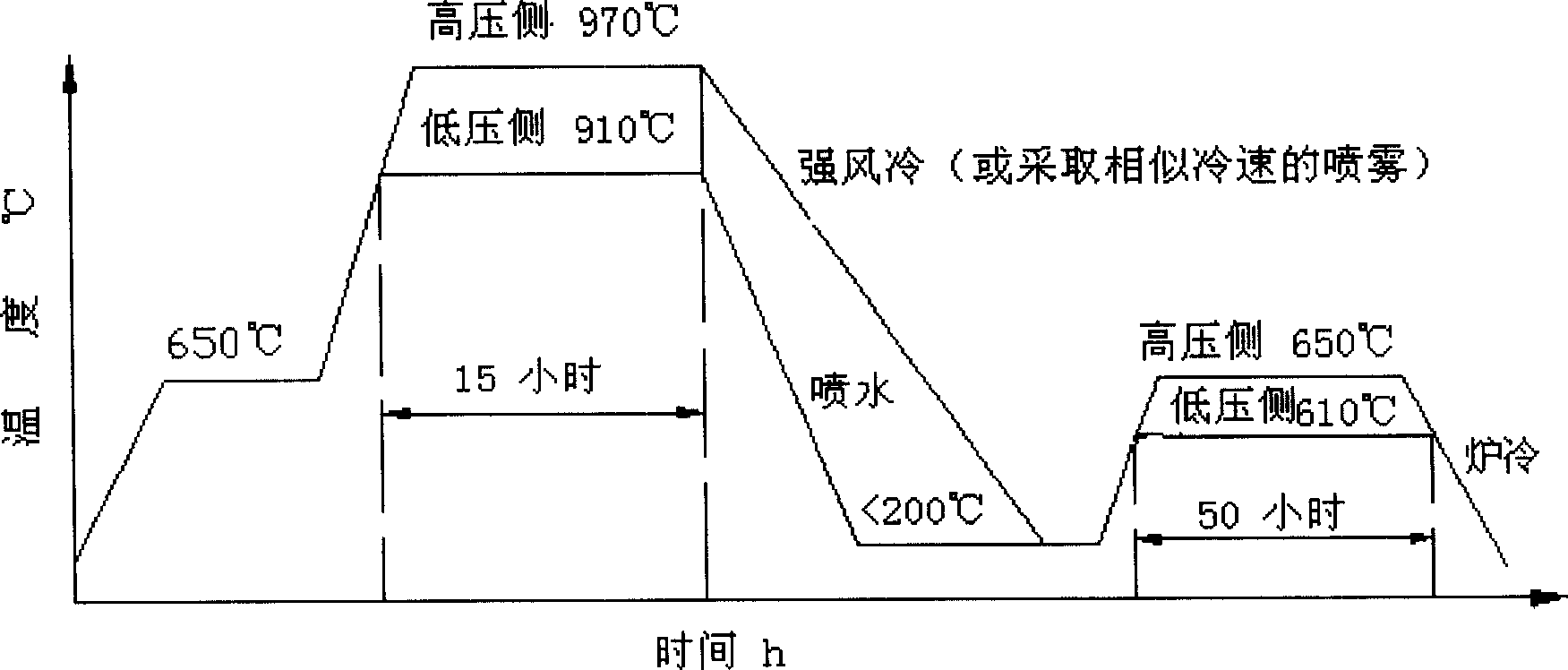

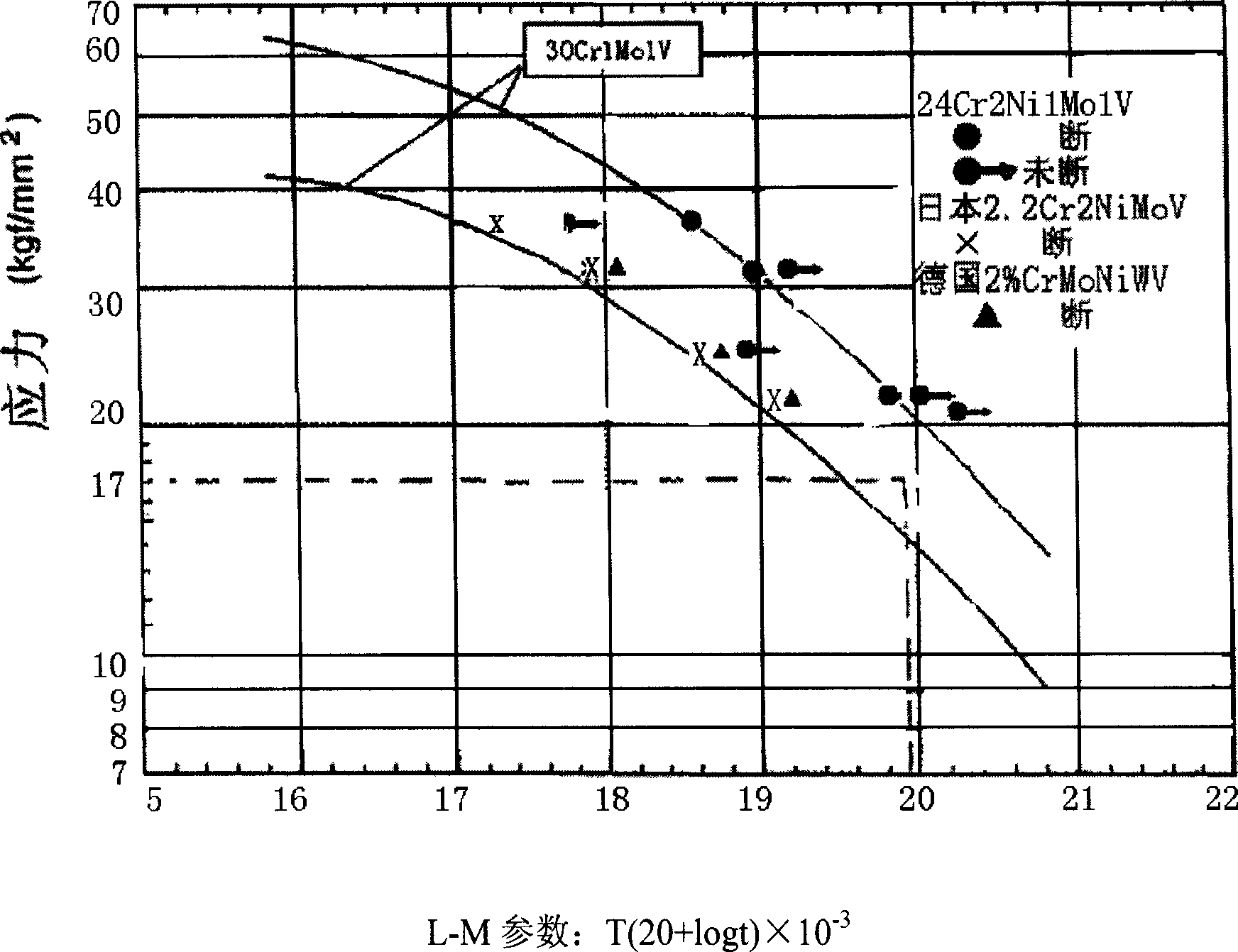

[0005] Specific Embodiment 1: The material used to manufacture the high and low pressure combined rotor of steam turbine in this embodiment is composed of the following components by weight percentage: C: 0.21-0.26%, Mn: 0.1-0.2%, Si: ≤0.05%, P: ≤0.005% , S: ≤0.005%, Cr: 2.2~2.55%, Ni: 1.3~1.55%, Mo: 1.1~1.35%, V: 0.2~0.31%, Cu: ≤0.05%, Al: ≤0.005%, Sn: ≤ 0.008%, Sb: ≤0.002%, As: ≤0.008%, and the balance is made of Fe. The manufacturing method of the material used to manufacture the high and low pressure combined rotor of the steam turbine in this embodiment is: smelting the above-mentioned components (electric furnace, double vacuum VCD)—forging—heat treatment after forging—performance heat treatment—inspection (conventional mechanical properties, short-term durability, Ultrasonic flaw detection) can be. After the rotor material is made, it is then machined to make the combined high and low pressure rotor of the steam turbine.

specific Embodiment approach 2

[0006] Specific embodiment two: The material used to manufacture the high and low pressure combined rotor of steam turbine in this embodiment consists of the following components by weight percentage C: 0.21%, Mn: 0.1%, Si: 0.03%, P: 0.001%, S: 0.001%, Cr: 2.2%, Ni: 1.3%, Mo: 1.1%, V: 0.2%, Cu: 0.01%, Al: 0.001%, Sn: 0.001%, Sb: 0.001%, As: 0.001%, and the balance is made of Fe become. Other methods are the same as in the first embodiment.

specific Embodiment approach 3

[0007] Specific embodiment three: The material used to manufacture the high and low pressure combined rotor of the steam turbine in this embodiment consists of the following components by weight percentage C: 0.26%, Mn: 0.2%, Si: 0.01%, P: 0.005%, S: 0.005%, Cr: 2.55%, Ni: 1.55%, Mo: 1.35%, V: 0.31%, Cu: 0.05%, Al: 0.005%, Sn: 0.007%, Sb: 0.002%, As: 0.008%, and the balance is made of Fe become. Other methods are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com