3D integral forging method for preparing high-alloyed alloy disc forgings

A technology of integral forging and disc-shaped forgings, applied in the field of forging, can solve the problems of high price, poor uniformity of structure, dead zone of deformation, etc., and achieve the effect of realizing industrialized production, easy industrialized production and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

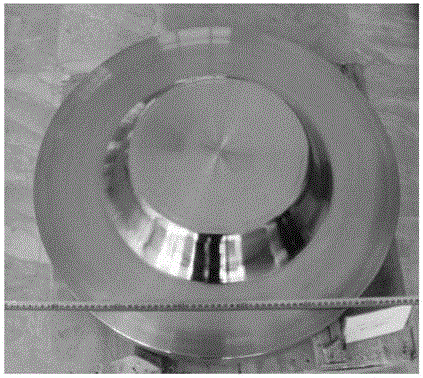

[0045] preparation ×120mm, nickel-based superalloy disk forgings with an average grain size of 6-7

[0046]The nominal chemical composition of nickel base superalloy is: C: 0.06wt%, Co: 12.5wt%, Cr: 16.5wt%, Mo: 4.2wt%, W: 4.2wt%, Ti: 3.5wt%, Al: 1.95wt% %, Nb: 0.6wt%, B: 0.012wt%, Zr: 0.03wt%, Fe: ≦0.5wt%, and the balance is Ni.

[0047] Such as figure 1 As shown, the 3D integral forging technology of Embodiment 1 includes the following steps:

[0048] a) Preparation of oriented ingot and high-temperature homogenization treatment: oriented ingot is a deformed nickel-based superalloy strengthened by γ′ phase or its related phase, which is prepared by vacuum / gas shielded electroslag remelting continuous directional solidification technology, with a size of ×1100mm. Oriented ingots are subjected to high-temperature homogenization treatment to eliminate microscopic segregation. The treatment temperature is lower than the solidus temperature (Ts) of the alloy and as high as ...

Embodiment 2

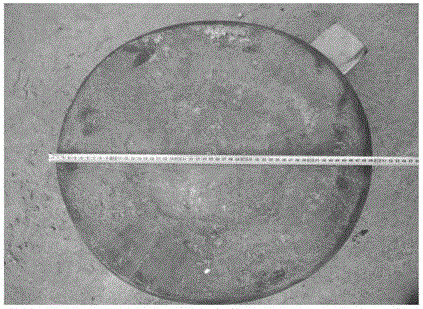

[0056] preparation ×80mm, nickel-based superalloy disk-shaped forgings with an average grain size of 8-9.

[0057] The nominal chemical composition of nickel-based superalloys is: C: 0.03wt%, Co: 21wt%, Cr: 13wt%, Mo: 3.8wt%, W: 2wt%, Ti: 3.7wt%, Al: 3.5wt%, Nb : 1.5wt%, Ta: 2.7wt%, B: 0.03wt%, Zr: 0.05wt%, Fe: ≦0.5wt%, and the balance is Ni.

[0058] Such as figure 1 As shown, the 3D integral forging technology of embodiment two comprises the following steps:

[0059] a) Preparation of oriented ingot and high-temperature homogenization treatment: oriented ingot is an alloy ingot prepared by vacuum / gas protection electroslag remelting continuous directional solidification technology, with a size of ×750mm. The homogenization heat treatment temperature of the ingot is controlled at 1180 ° C ~ 1220 ° C, and the holding time is not less than 30 hours;

[0060] b) Axial ingot billet opening: billet forging is completed after 2 to 4 fires, the forging temperature is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com