Method for oxidative degradation of heavy metal complex and recovery of heavy metal through MXene reinforced Fenton

A technology of Fenton oxidation and heavy metals, which is applied in chemical instruments and methods, water treatment of special compounds, oxidized water/sewage treatment, etc., can solve the problems of large consumption of acid and alkali reagents, inability to realize simultaneous removal and recovery of high value-added heavy metals, etc. , to achieve the effect of simplifying the process flow, enhancing removal and promoting activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

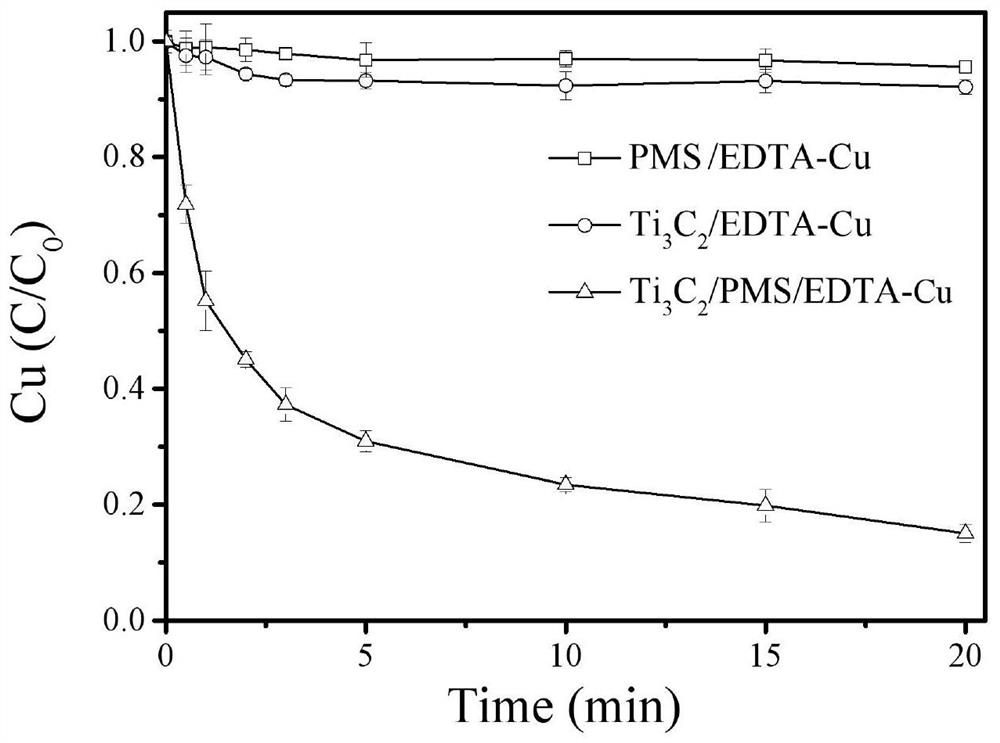

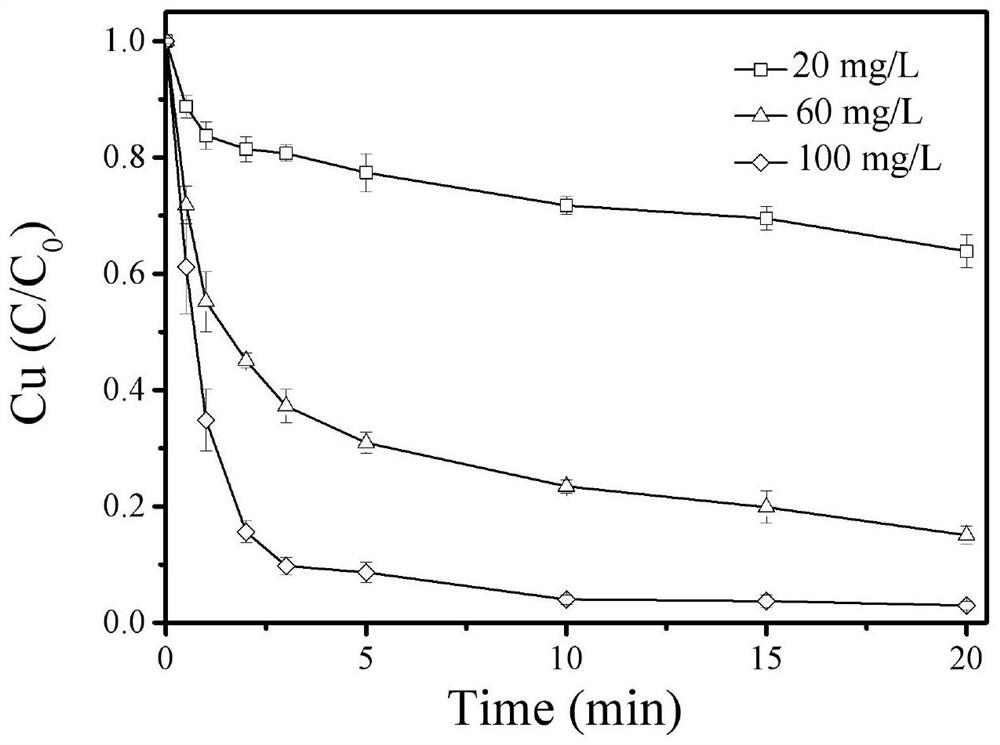

[0028] A method for MXene-enhanced Fenton-like oxidation degradation of heavy metal complexes and recovery of heavy metals, the specific steps are as follows:

[0029] (1) Choose Ti 3 C 2 For MXene, the target pollutant is ethylenediaminetetraacetic acid copper complex (EDTA-Cu), and the oxidant is potassium monopersulfate (PMS). Add 50μM EDTA-Cu solution, 60mg / LTi 3 C 2 and 1 mM potassium persulfate. A magnetic stirrer was used to stir rapidly at a stirring speed of 500 rpm. After 20 minutes of reaction, an inductively coupled plasma mass spectrometer (ICP-MS) was used to measure the Cu element concentration in the reaction solution, and the removal rate of Cu ions was 85%.

[0030] (2) Leave the solution after the reaction in step (1) to stand or filter to separate the solid from the liquid, use pickling solution to clean the precipitate or filter residue, and recover heavy metals.

[0031] (3) The washed MXene was freeze-dried at -10°C for 24 h and reused.

Embodiment 2

[0033] A method for MXene-enhanced Fenton-like oxidation degradation of heavy metal complexes and recovery of heavy metals, the specific steps are as follows:

[0034] (1) Choose Ti 3 C 2 MXene, copper citrate complex was selected as the target pollutant, and sodium persulfate was selected as the oxidant. Add 50μM copper citrate complex solution, 100mg / L Ti 3 C 2 and 2mM sodium persulfate. A magnetic stirrer was used to stir rapidly at a stirring speed of 700 rpm. After reacting for 90 minutes, an inductively coupled plasma mass spectrometer (ICP-MS) was used to measure the Cu element concentration in the reaction solution, and the removal rate of Cu ions was 97%.

[0035] (2) Leave the solution after the reaction in step (1) to stand or filter to separate the solid from the liquid, use pickling solution to clean the precipitate or filter residue, and recover heavy metals.

[0036] (3) The washed MXene was freeze-dried at a temperature below -20 °C for 23 h and then reus...

Embodiment 3

[0038] A method for MXene-enhanced Fenton-like oxidation degradation of heavy metal complexes and recovery of heavy metals, the specific steps are as follows:

[0039] (1) Choose Nb 2 C MXene, the target pollutant is ethylenediaminetetraacetic acid iron complex (EDTA-Fe), and the oxidant is hydrogen peroxide. Add 50μM EDTA-Fe solution, 10mg / LNb 2 C and 20 mM hydrogen peroxide. A magnetic stirrer was used to stir rapidly at a stirring speed of 500 rpm. After 30 minutes of reaction, an inductively coupled plasma mass spectrometer (ICP-MS) was used to measure the concentration of Fe in the reaction solution, and the removal rate of Fe ions was 92%.

[0040] (2) Leave the solution after the reaction in step (1) to stand or filter to separate the solid from the liquid, use pickling solution to clean the precipitate or filter residue, and recover heavy metals.

[0041] (3) The washed MXene was freeze-dried at a temperature below -30 °C for 24 h and then reused.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com