Preparation method and preparation apparatus of spherical graphite for power battery

A technology of spherical graphite and earthy graphite, applied in the directions of graphite, secondary batteries, battery electrodes, etc., can solve the problems of reducing the median particle size of spherical graphite, unable to meet the requirements of high-end power batteries, and difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

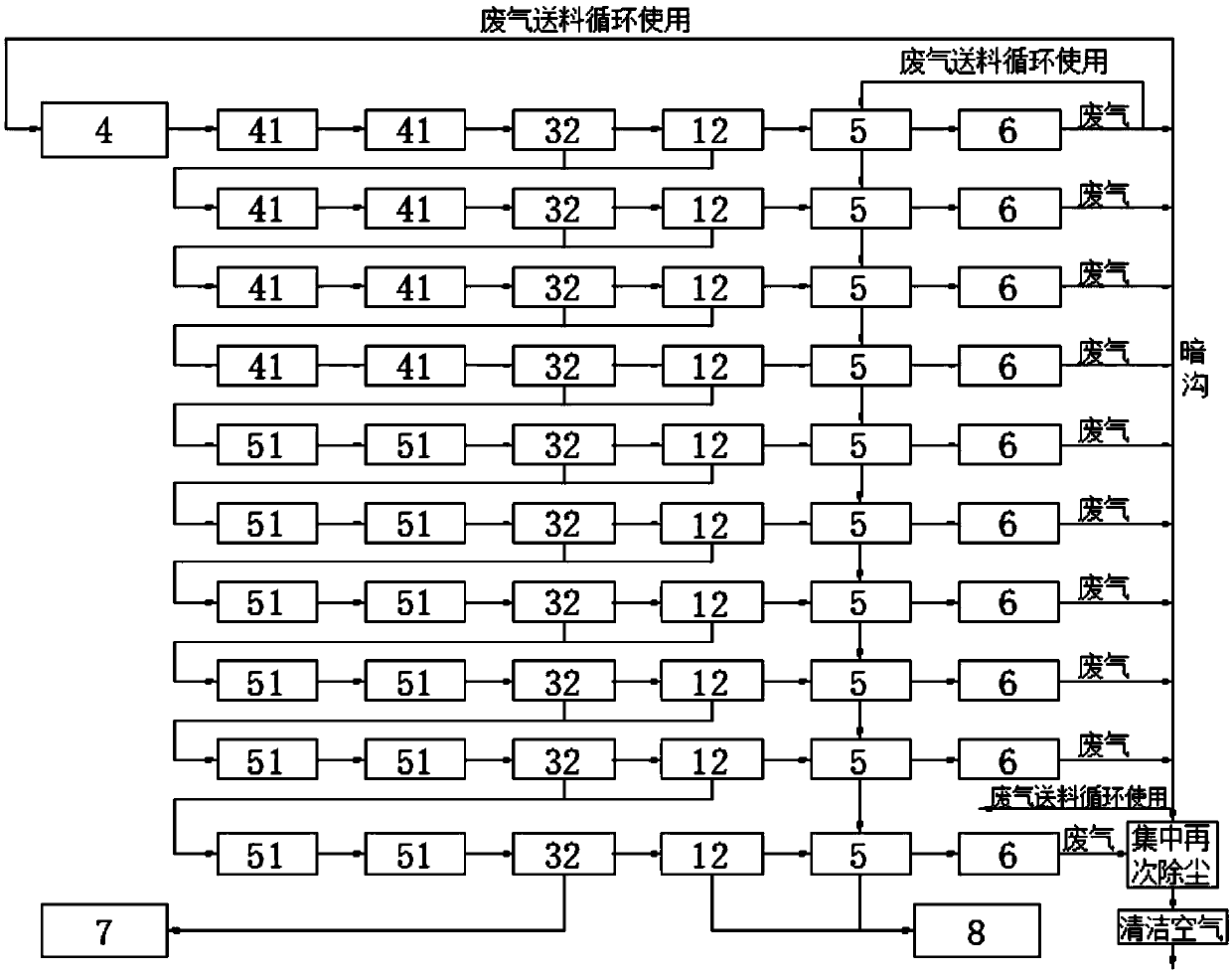

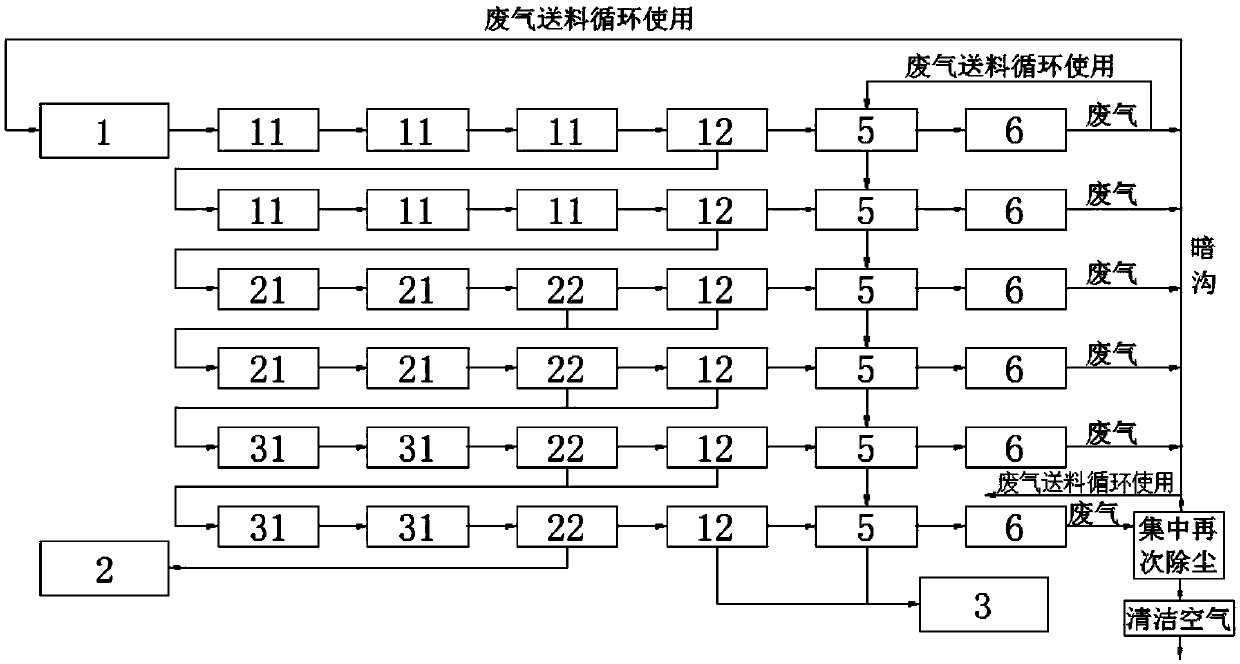

[0079] The process flow of Examples 1-9 is as above, the specific process parameters are shown in Table 1, the test data of Examples 1-9 are shown in Table 2, and the process parameters of Preparation Examples 1-7 are shown in Table 3.

[0080] The processing parameter of table 1 embodiment 1-9

[0081]

[0082]

[0083] The 3 sets of 2 units in series in the superfine primary grinding in the step (1) mentioned in the above table means that 3 sets of superfine primary grinding units are connected in series, and each group of ultrafine primary grinding units connects 2 sets of superfine grinding units in series. machine; others such as 4 groups of 2 have the same meaning, so I won’t repeat them here.

[0084]In the super fine grinding of step (2) mentioned in the above table, the 2 groups of 2 units connected in series 1000rpm~2000rpm gradually increase, each time for 20min, and the 5 groups of 2 units connected in series 1600rpm~500rpm gradually decrease, and each time 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com