Rock plate with engraved textures and preparation method thereof

A technology of texture and slate, applied in the field of slate with carved texture and its preparation, can solve the problems of manpower and material resources consumption, product grade decline, texture mold and surface pattern texture deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

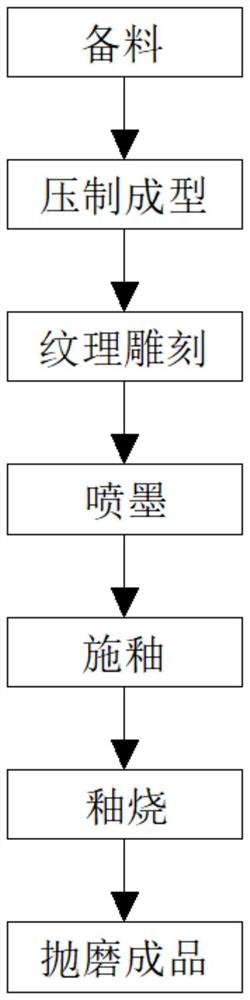

Method used

Image

Examples

Embodiment 1

[0038] A rock slab with engraved texture, including blank body, auxiliary additives and ink;

[0039] The body includes 8 parts by weight of Guangfeng water scrub, 7 parts of Jiahui powder, 3 parts of burnt talc, 25 parts of 102 stone powder, 7 parts of super white material, 34 parts of FC ball soil, 11 parts of Jingle water scrub, 5 parts of Tianhe soil, wherein the chemical composition of the green body includes the following parts by weight: 65 parts of SiO2, 20 parts of Al2O3, 0.1 part of Fe2O3, 0.1 part of TiO2, 5 parts of CaO, 2 parts of MgO, 2 parts of K2O, 5 parts of Na2O;

[0040] Auxiliary additives include 10 parts by weight of sodium hydroxymethyl cellulose, 5 parts of polymer reinforcing agent, 3 parts of decoagulant No. 2, 60 parts of sodium tripolyphosphate, 10 parts of diluent, and 12 parts of water glass, of which The viscosity of sodium hydroxymethyl cellulose is 2000cP, the moisture is 10%, the flow rate of polymer reinforcing agent is 28 seconds, and the st...

Embodiment 2

[0051] A rock slab with engraved texture, including blank body, auxiliary additives and ink;

[0052] The green body includes 10 parts by weight of Guangfeng water scrub, 6 parts of Jiahui powder, 4 parts of burnt talc, 20 parts of 102 stone powder, 6 parts of super white material, 32 parts of FC ball clay, 15 parts of Jingle water scrub, 4 parts of Tianhe soil, wherein the chemical composition of the green body includes the following parts by weight: 62 parts of SiO2, 25 parts of Al2O3, 1 part of Fe2O3, 0.1 part of TiO2, 1 part of CaO, 1 part of MgO, 1 part of K2O, and 1 part of Na2O3;

[0053] Auxiliary additives include 12 parts by weight of sodium hydroxymethyl cellulose, 3 parts of polymer reinforcing agent, 2 parts of decoagulant No. 2, 60 parts of sodium tripolyphosphate, 8 parts of diluent, and 10 parts of water glass, of which Sodium hydroxymethyl cellulose viscosity 2000cP, moisture 10%, macromolecular reinforcing agent flow rate 30 seconds, strength 2MPa, decoagulan...

Embodiment 3

[0064] A rock slab with engraved texture, including blank body, auxiliary additives and ink;

[0065] The body includes 12 parts by weight of Guangfeng water scrub, 5 parts of Jiahui powder, 5 parts of burnt talc, 25 parts of 102 stone powder, 5 parts of super white material, 30 parts of FC ball soil, 10 parts of Jingle water scrub, 3 parts of Tianhe soil, wherein the chemical composition of the green body includes the following parts by weight: 60 parts of SiO2, 30 parts of Al2O3, 0.5 parts of Fe2O3, 0.5 parts of TiO2, 5 parts of CaO, 3 parts of MgO, 1 part of K2O, 2 parts of Na2O;

[0066] Auxiliary additives include 15 parts by weight of sodium hydroxymethyl cellulose, 5 parts of polymer reinforcing agent, 3 parts of decoagulant No. 2, 65 parts of sodium tripolyphosphate, 10 parts of diluent, and 12 parts of water glass, of which The viscosity of sodium hydroxymethyl cellulose is 2000cP, the moisture is 10%, the flow rate of polymer reinforcing agent is 32 seconds, the stre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com