Method for preparing chromatic vanadium dioxide thermo-color on glass substrate

A technology of vanadium dioxide and glass substrate is applied in the field of preparation of colored vanadium dioxide thermochromic glass to achieve the effect of beautifying the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

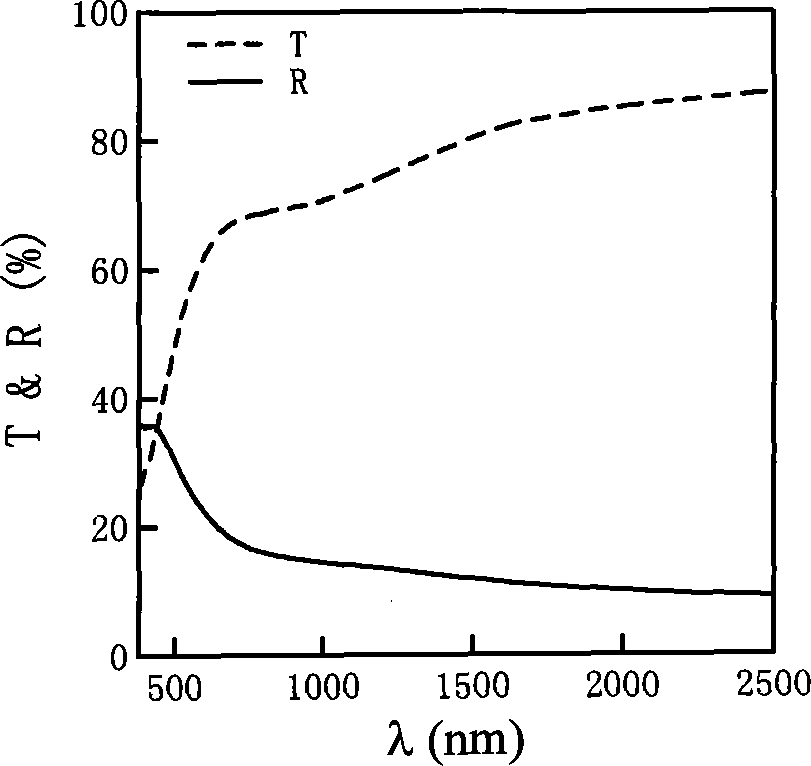

Embodiment 1

[0028] (a) Cleaning of glass substrate

[0029] Put the glass substrate into high-purity alcohol and clean it ultrasonically for 5 minutes; then put it into acetone solution and clean it ultrasonically for 5 minutes. It was then blown dry with nitrogen and immediately placed in the film preparation chamber.

[0030] (b) Preparation of vanadium dioxide thin film

[0031] Preparation system: Magnetron sputtering is used. The magnetron sputtering system consists of a sample mounting chamber and a main sputtering chamber (45 cm in diameter). The main sputtering chamber is connected with a molecular diffusion pump with a vacuum of 2.0×10 -6 Pa. The sputtering chamber has three target positions for three different 2-inch diameter targets. Each target position is inclined upward at an angle of 30°, and can be co-sputtered in a confocal manner or independently sputtered with three targets. The sample stage can be heated up to 600°C and can rotate continuously during the sputteri...

Embodiment 2

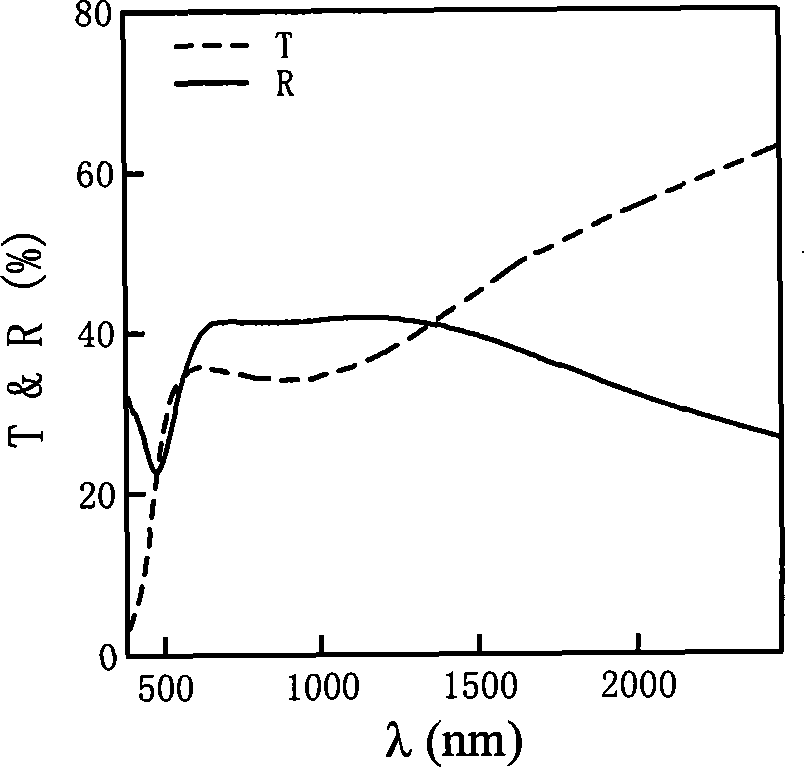

[0037] The cleaning, preparation system and preparation conditions of the glass substrate are the same as in Example 1. The deposition time of the vanadium dioxide thin film is 32 minutes, and the film thickness is 65 nm. Viewed from the coated surface of the glass, the reflection color of the glass is light orange-yellow. Transmission spectrum and reflection spectrum see figure 2 .

Embodiment 3

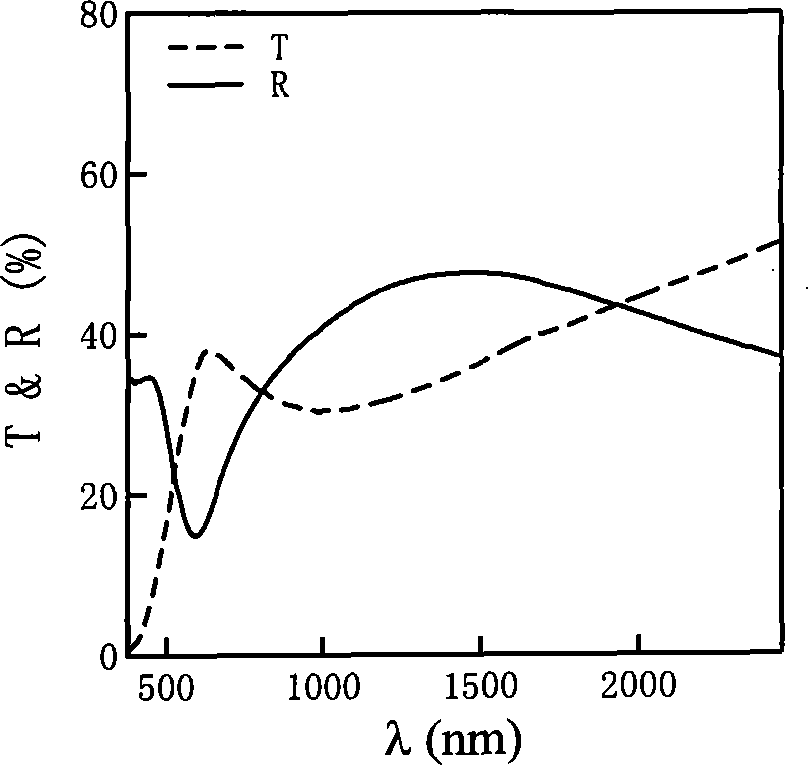

[0039] The cleaning and preparation system of the glass substrate is the same as in Example 1.

[0040] Preparation conditions: use vanadium pentoxide ceramics as the sputtering target (purity 99.5%), feed Ar gas and H 2 Gas mixture [mixing ratio H 2 / (Ar+H 2 )=5%], the flow rate is 30 sccm, DC sputtering, and the sputtering power is set to 120W. Sputtering for 40 minutes, VO 2 The film thickness is about 95 nm. The deposition temperature was 500°C.

[0041] Viewed from the coated surface of the glass, the reflection color of the glass is royal blue. Transmission spectrum and reflection spectrum see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com