Method for treating alkaline printing and dyeing wastewater by utilizing waste acid

A technology for the treatment of printing and dyeing wastewater and waste acid, which is applied in textile industry wastewater treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. Deal with the problems of high cost, achieve the effect of saving clean water, excellent decolorization effect, and saving acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

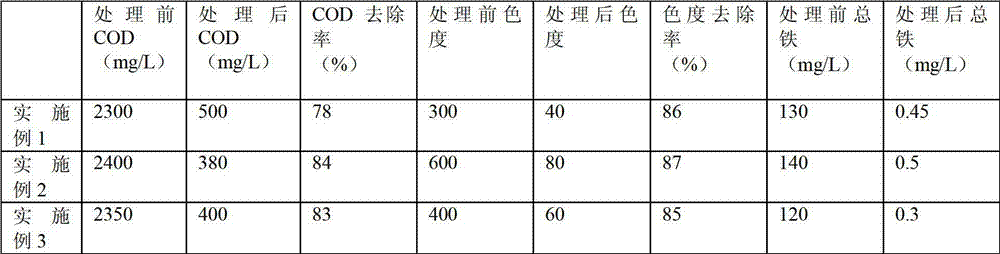

Embodiment 1

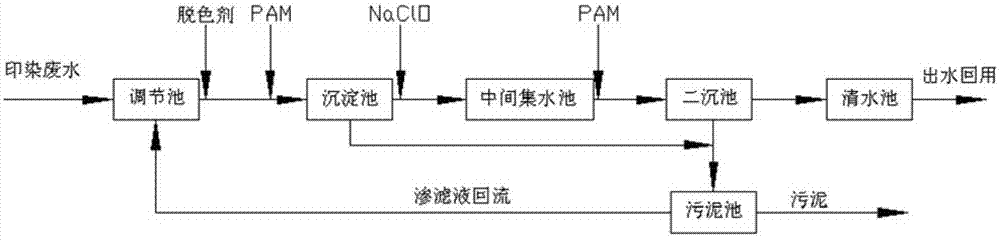

[0042] A method for treating alkaline printing and dyeing wastewater with waste acid, comprising the following steps:

[0043] 1) Alkaline printing and dyeing wastewater, enter the adjustment tank for pH measurement, and adjust the pH value to ensure that the pH value is between 11 and 13. When the pH value is too low, the effect of the waste acid decolorizer is not obvious.

[0044] 2) Transport the pH-adjusted wastewater from the adjustment tank to the sedimentation tank through pipelines. In the outlet pipeline of the adjustment tank, add pickling waste liquid according to the dosage of 3‰ of the wastewater weight, so that the wastewater and waste acid decolorizer are in the Mix well in the pipe. If the decolorizing effect is not good, the mixing time of the decolorizing agent and wastewater can be extended to increase the mixing effect.

[0045] 3) Add polyacrylamide according to the dosing amount of 0.3ppm into the pipeline where the decolorized wastewater enters the sed...

Embodiment 2

[0049] A method for treating alkaline printing and dyeing wastewater with waste acid, comprising the following steps:

[0050] 1) Alkaline printing and dyeing wastewater, enter the adjustment tank for pH measurement, and adjust the pH value to ensure that the pH value is between 11 and 13. When the pH value is too low, the effect of the waste acid decolorizer is not obvious.

[0051] 2) Transport the pH-adjusted wastewater from the adjustment tank to the sedimentation tank through pipelines. In the outlet pipeline of the adjustment tank, add pickling waste liquid according to the dosage of 5‰ of the wastewater weight, so that the wastewater and waste acid decolorizer are in the Mix well in the pipe. If the decolorizing effect is not good, the mixing time of the decolorizing agent and wastewater can be extended to increase the mixing effect.

[0052] 3) Add polyacrylamide according to the dosing amount of 1ppm into the pipeline where the decolorized wastewater enters the sedim...

Embodiment 3

[0056] A method for treating alkaline printing and dyeing wastewater with waste acid, comprising the following steps:

[0057] 1) Alkaline printing and dyeing wastewater, enter the adjustment tank for pH measurement, and adjust the pH value to ensure that the pH value is between 11 and 13. When the pH value is too low, the effect of the waste acid decolorizer is not obvious.

[0058] 2) Transport the pH-adjusted wastewater from the adjustment tank to the sedimentation tank through pipelines. In the outlet pipeline of the adjustment tank, add pickling waste liquid according to the dosage of 8‰ of the wastewater weight, so that the wastewater and waste acid decolorizer are in the Mix well in the pipe. If the decolorizing effect is not good, the mixing time of the decolorizing agent and wastewater can be extended to increase the mixing effect.

[0059] 3) Add polyacrylamide according to the dosing amount of 1.5ppm into the pipeline where the decolorized wastewater enters the sed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com