Method for externally expanding single edge of circuit of touch panel

A touch panel, unilateral technology, used in chemical/electrolytic methods to remove conductive materials, data processing input/output processes, instruments, etc. The effect of electrical signal transmission, strong operation controllability, and reduction of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The thickness of the nameplate layer is 0.7 mm; the thickness of the metal conductive material is 0.05 micron; the thickness of the transparent conductive material is 0.045 micron; the thickness of the substrate layer is 50 micron, and the substrate layer is polycarbonate resin.

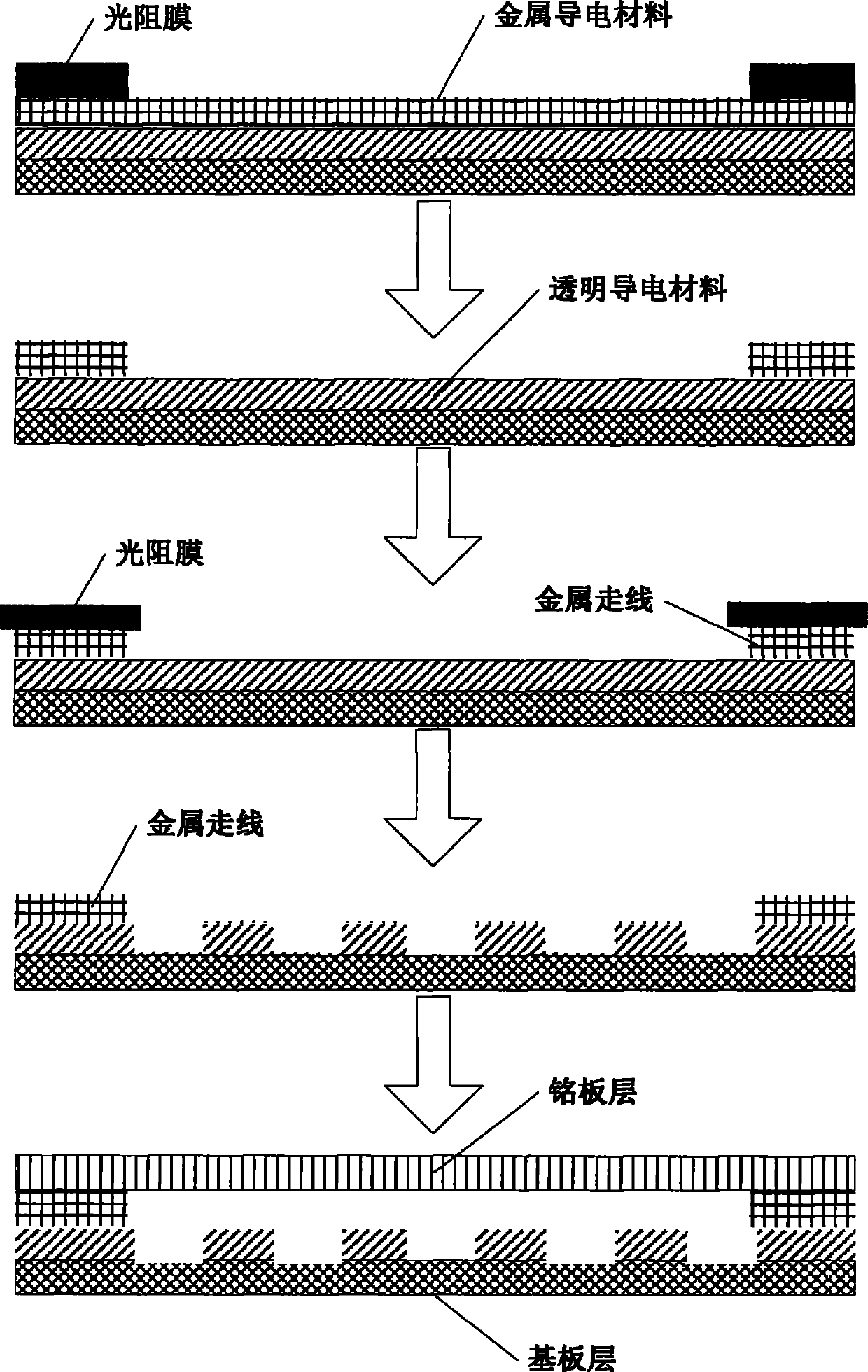

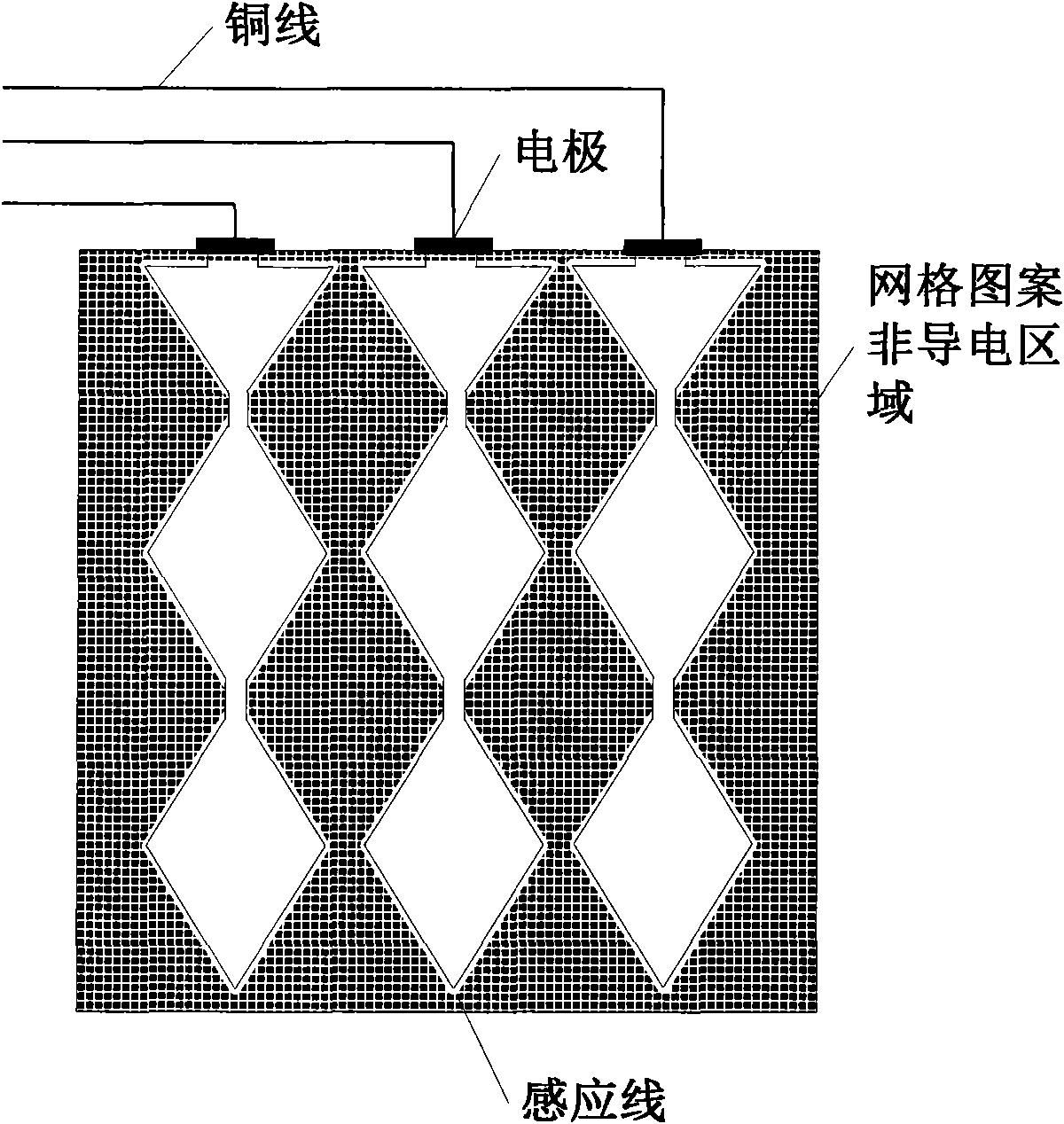

[0024] The method for unilateral expansion of the touch panel circuit includes the following steps to be carried out under dust-free and dry conditions;

[0025] Step 1: electroplating metal conductive material on the surface of transparent conductive material;

[0026] Step 2: paste a photoresist film on the metal conductive material, expose, develop and etch to form a metal trace; at room temperature, etch the metal conductive material with a mixed solution of sulfuric acid and hydrogen peroxide to obtain a metal trace;

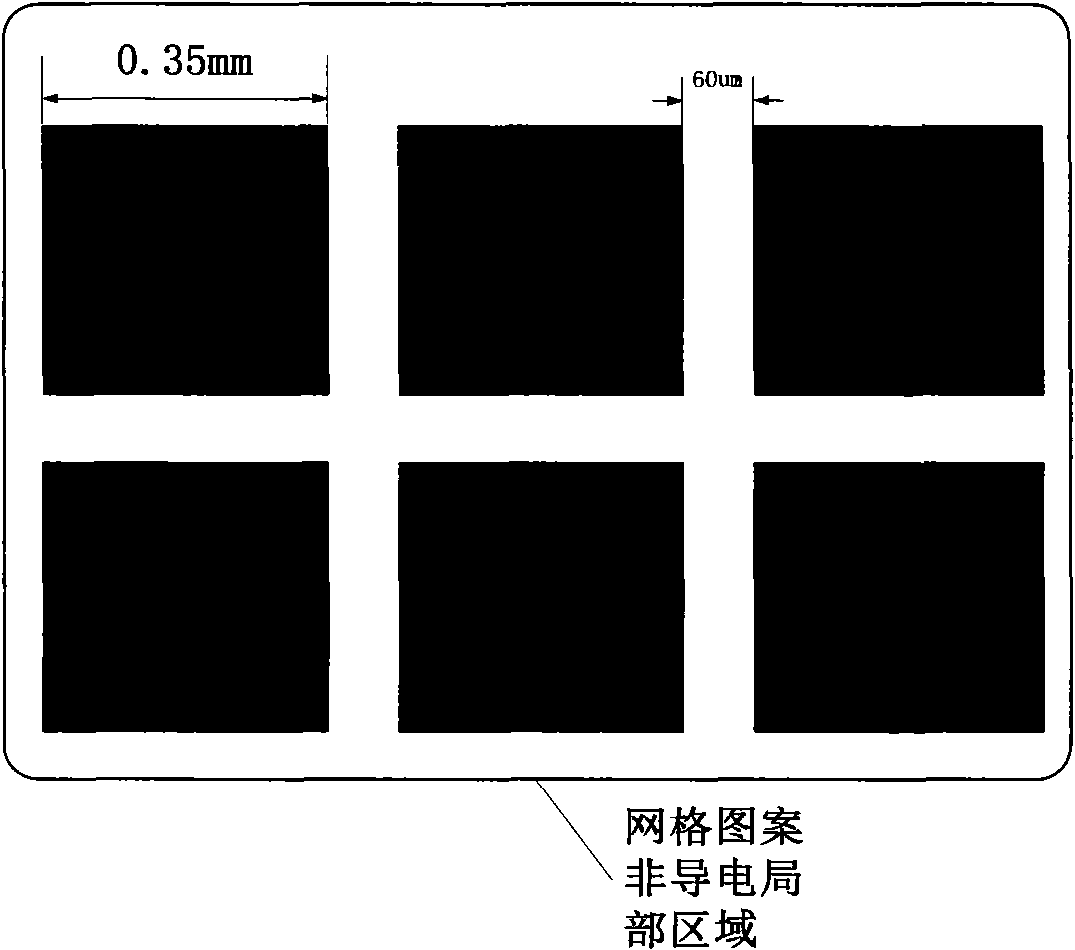

[0027] Step 3: first attach a photoresist film on the metal traces, wherein the width of the photoresist film on a single metal trace is 65 microns; then, expose and develo...

Embodiment 2

[0031] The thickness of the nameplate layer is 1.8 mm; the thickness of the metal conductive material is 0.1 micron; the thickness of the transparent conductive material is 0.1 micron; the thickness of the substrate layer is 180 micron, and the substrate layer is hardened glass.

[0032] The method for unilateral expansion of the touch panel circuit includes the following steps to be carried out under dust-free and dry conditions;

[0033] Step 1: electroplating metal conductive material on the surface of transparent conductive material;

[0034] Step 2: paste a photoresist film on the metal conductive material, expose, develop and etch to form a metal trace; at room temperature, etch the metal conductive material with a mixed solution of sulfuric acid and hydrogen peroxide to obtain a metal trace;

[0035] Step 3: first attach a photoresist film on the metal traces, wherein the width of the photoresist film on a single metal trace is 75 microns; then, expose and develop to et...

Embodiment 3

[0039] The thickness of the nameplate layer is 1.1 mm; the thickness of the metal conductive material is 0.09 microns; the thickness of the transparent conductive material is 0.08 microns; the thickness of the substrate layer is 125 microns, and the substrate layer is polycarbonate resin.

[0040] The method for unilateral expansion of the touch panel circuit includes the following steps to be carried out under dust-free and dry conditions;

[0041] Step 1: electroplating metal conductive material on the surface of transparent conductive material;

[0042] Step 2: paste a photoresist film on the metal conductive material, expose, develop and etch to form a metal trace; at room temperature, etch the metal conductive material with a mixed solution of sulfuric acid and hydrogen peroxide to obtain a metal trace;

[0043] Step 3: first attach a photoresist film on the metal traces, wherein the width of the photoresist film on a single metal trace is 70 microns; then, expose and dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com