Method of manufacturing grid pattern type touch panel

A touch panel and grid manufacturing technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc. Inaccurate positioning and other issues, to achieve the effect of improving light transmittance and touch sensitivity, reducing etching marks, and reducing thickness and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

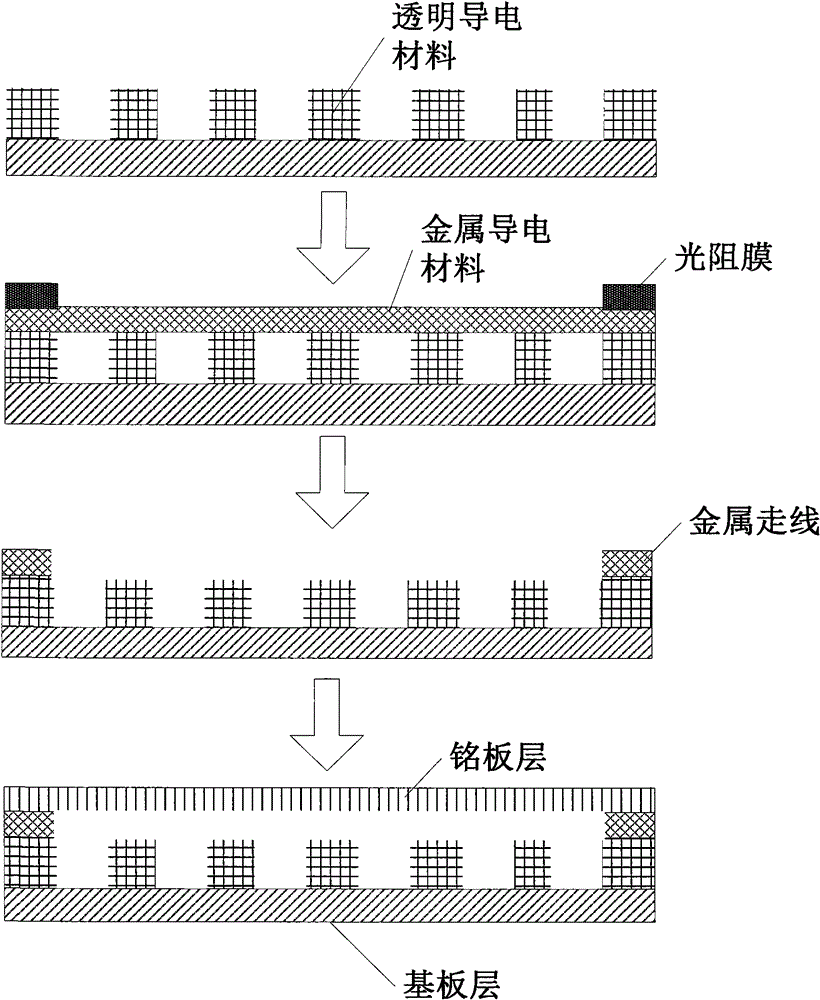

[0025] The thickness of the nameplate layer is 0.7 mm; the thickness of the metal conductive material is 0.04 microns; the thickness of the transparent conductive material is 0.045 mm; the thickness of the substrate layer is 50 microns, and the substrate layer is polycarbonate resin.

[0026] A method for manufacturing a grid-patterned touch panel, comprising the following steps carried out under dust-free and dry conditions;

[0027] Step 1: Aging crystallization of transparent conductive materials;

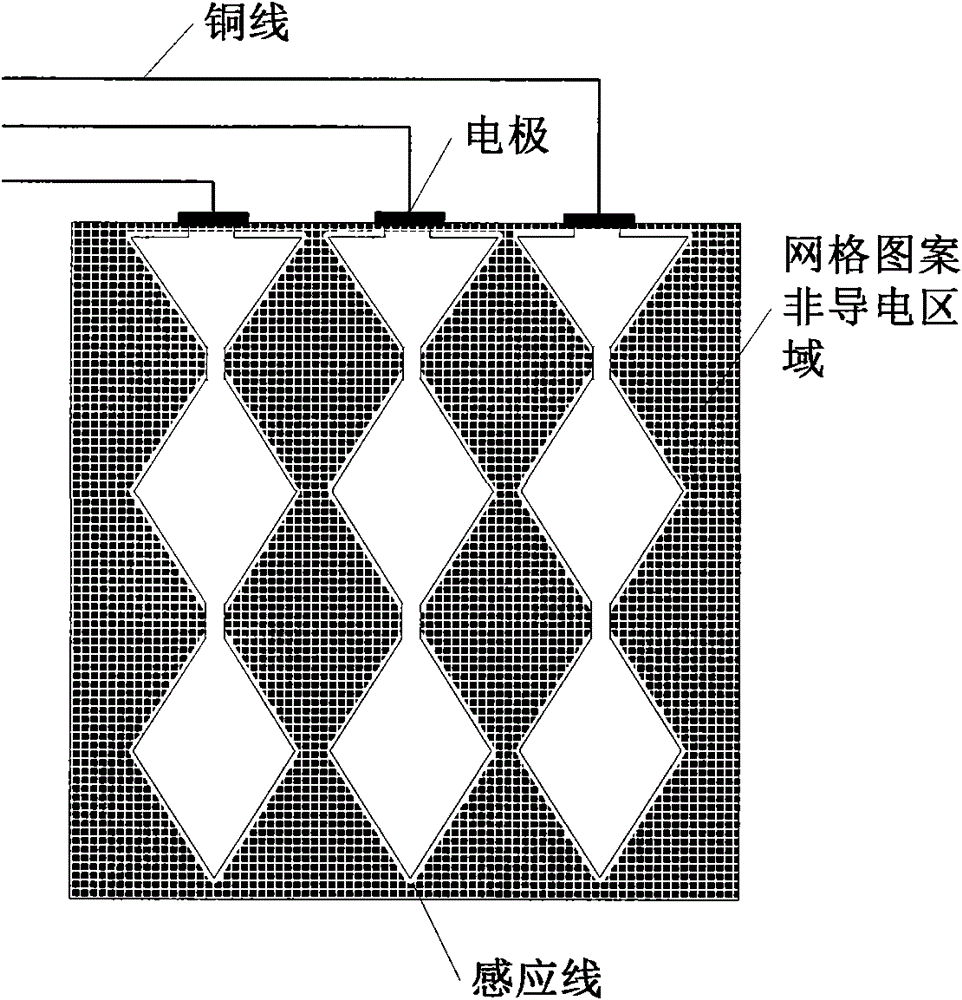

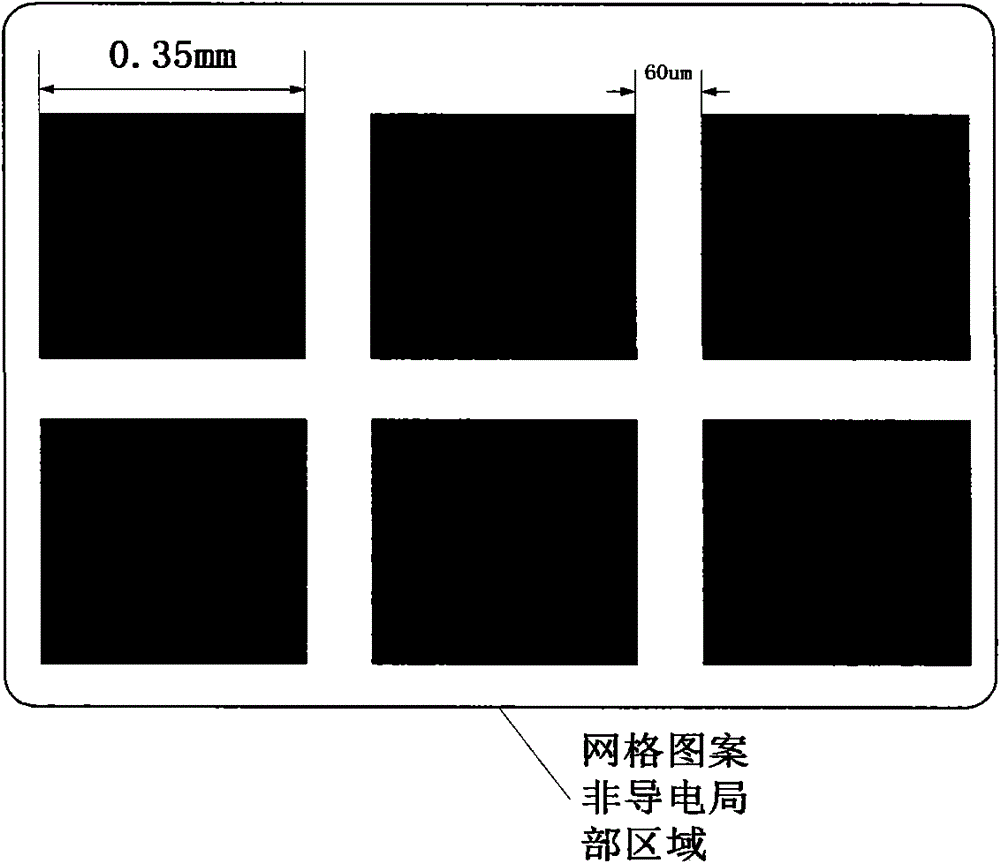

[0028] Step 2: Expose and etch the aging crystalline transparent conductive material, etch the transparent conductive material with hydrochloric acid at a temperature of 40 degrees Celsius to form a non-conductive area of induction lines and grid patterns;

[0029] Step 3: In step 2, the surface of the transparent conductive material is electroplated with a metal conductive material;

[0030] Step 4: paste a photoresist film on the metal conductive material, expose, develop a...

Embodiment 2

[0034] The thickness of the nameplate layer is 1.8 mm; the thickness of the metal conductive material is 0.1 micron; the thickness of the transparent conductive material is 0.1 micron; the thickness of the substrate layer is 180 micron, and the substrate layer is hardened glass.

[0035] A method for manufacturing a grid-patterned touch panel, comprising the following steps carried out under dust-free and dry conditions;

[0036] Step 1: Aging crystallization of transparent conductive materials;

[0037] Step 2: Expose and etch the aging crystalline transparent conductive material, etch the transparent conductive material with hydrochloric acid at a temperature of 40 degrees Celsius to form a non-conductive area of induction lines and grid patterns;

[0038] Step 3: In step 2, the surface of the transparent conductive material is electroplated with a metal conductive material;

[0039] Step 4: paste a photoresist film on the metal conductive material, expose, develop and et...

Embodiment 3

[0043] The thickness of the nameplate layer is 1.1 mm; the thickness of the metal conductive material is 0.08 microns; the thickness of the transparent conductive material is 0.07 microns; the thickness of the substrate layer is 125 microns, and the substrate layer is polycarbonate resin.

[0044] A method for manufacturing a grid-patterned touch panel, comprising the following steps carried out under dust-free and dry conditions;

[0045] Step 1: Aging crystallization of transparent conductive materials;

[0046] Step 2: Expose and etch the aging crystalline transparent conductive material, etch the transparent conductive material with hydrochloric acid at a temperature of 40 degrees Celsius to form a non-conductive area of induction lines and grid patterns;

[0047] Step 3: In step 2, the surface of the transparent conductive material is electroplated with a metal conductive material;

[0048] Step 4: paste a photoresist film on the metal conductive material, expose, deve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com