Novel low-expansion high-thermal-conductivity micro-channel bottom plate

A micro-channel, low-expansion technology, used in semiconductor devices, cooling/ventilation/heating transformation, semiconductor/solid-state device components, etc., can solve the problems of reducing system thickness and size, high thermal conductivity, low thermal expansion coefficient, etc. The effect of improving the heat dissipation capacity, reducing the thickness and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

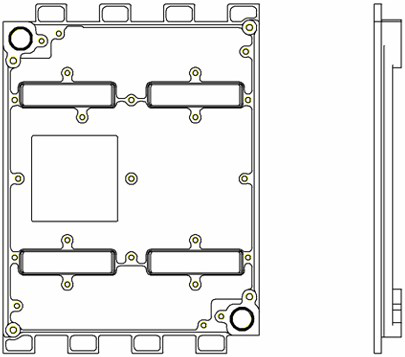

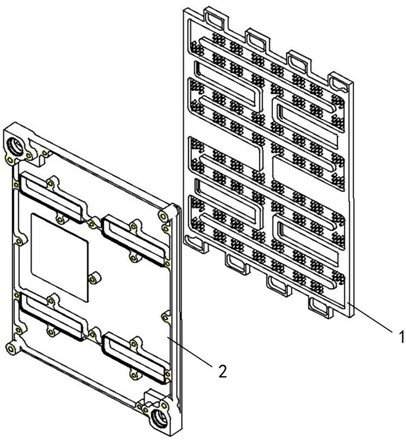

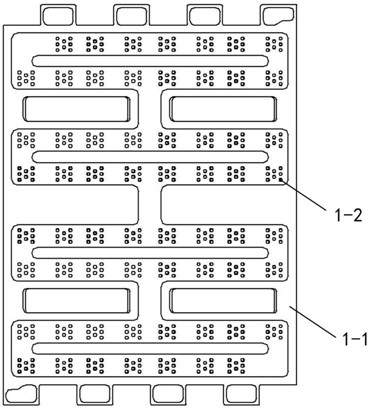

[0038] like figure 1 As shown, a novel low expansion and high thermal conductivity microchannel bottom plate of the present invention includes a microchannel composite cavity 1 and a composite cover plate 2 .

[0039] The micro-channel composite cavity 1 has an external shape of a special-shaped composite metal plate, which is formed by spatial compounding of Al / SiC (65%) and aluminum alloy 3A21, and the external dimension is 142 × 104 × 3 (mm). The main body of the micro-channel composite base plate is a SiC / Al matrix 1-1: one side is flat, which is used for welding power devices with low expansion coefficient; the other panel is distributed with open serpentine water channels, and aluminum alloy cooling columns are arranged inside the water channels 1-2 to enhance cooling capacity. The diameter of the aluminum alloy heat dissipation column is φ1mm and the height is 2mm. The spatial arrangement comprehensively considers the position of the heating device, the flow resistance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com