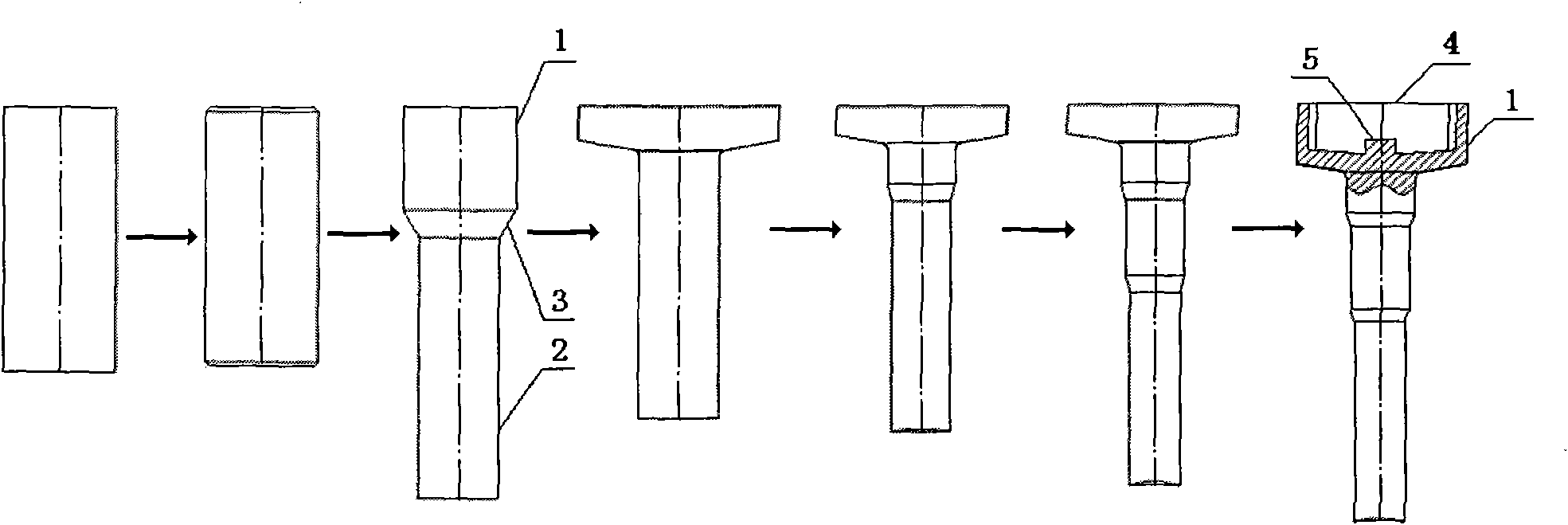

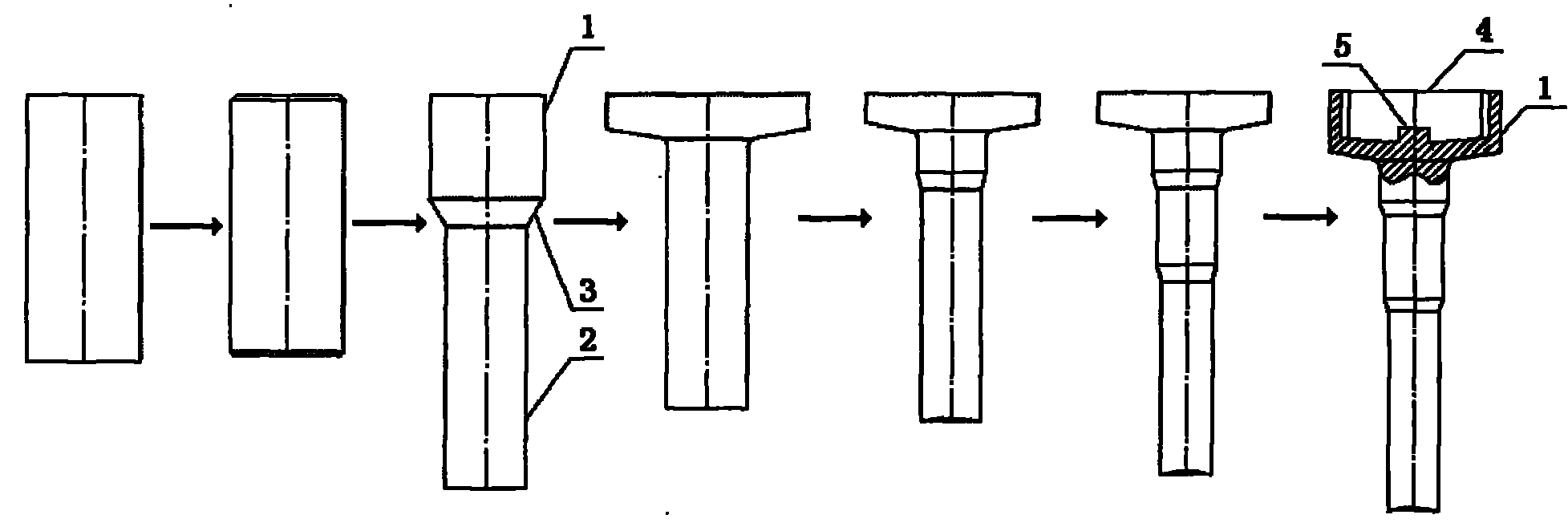

Cold forging precise forming process for mechanical transmission gear shaft

A mechanical transmission and precision forming technology, applied in the direction of mechanical equipment, engine components, etc., can solve the problems of complex processing and high production cost, and achieve the effect of simple processing method, good consistency and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: A cold forging precision forming process of a mechanical transmission gear shaft, comprising the following steps:

[0022] a. Blanking, intercepting the bar, blanking the alloy steel bar with a circular saw machine according to the length of the gear shaft, the weight error of the blank is ±1 gram;

[0023] b, annealing, annealing the bar, the annealing temperature is 860°C, keep it warm for 6 hours, and cool it to 300°C with the furnace;

[0024] c. Shot blasting, phosphating, and saponification treatment. Phosphate and saponify the annealed bar according to the conventional process by using the phosphorus saponification line to form a surface lubricating layer. The phosphating temperature is 70°C and the time is 20 minutes; saponification The temperature is 60°C, and the time is 10 minutes;

[0025] d. Reduced diameter extrusion: use a 400T mechanical press, four-column universal formwork and a positive extrusion die, and positively extrude one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com