Patents

Literature

73results about How to "Improve cost competitiveness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

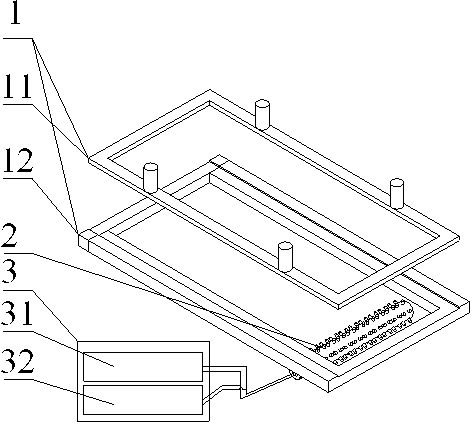

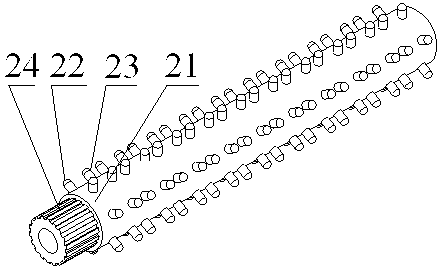

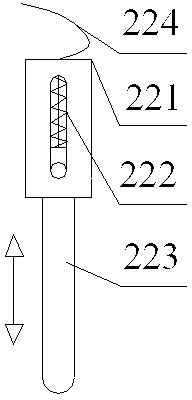

Detection device and method for LED chip and device

ActiveCN103323762ANo poor contactFlexibleIndividual semiconductor device testingElectricityPower flow

The invention discloses a detection device and method for a LED chip and a device. The device comprises a blue film or a device substrate clamping jig, an annular array testing electrode, and a power supply and electrical parameter acquisition system. The annular array testing electrode is roller-shaped in appearance and provided with multiple groups of positive and negative test probes. When detection is carried out, the detection device is driven through a synchronous pulley to enable the positive and negative test probes to be exactly contacted with a positive electrode and a negative electrode of an LED chip to be tested or exactly contacted with a positive electrode and a negative electrode of a device, sweep currents are connected into a list of probes contacted with a substrate right now through a power supply in sequence, electrical parameters of the device are collected at the same time, and the synchronous pulley drives the device to roll to the next adjacent list of probes after collection is completed, and the next list of LED chips or devices are tested. The technical method is extremely high in efficiency, detection efficiency can be improved by 6-10 times compared with a traditional detection method, the detection device is applied to the LED industry, detection efficiency of LED products is greatly improved, equipment loss is reduced, product cost competitive advantages are promoted, and the detection device has good industrialization application prospects.

Owner:SOUTH CHINA UNIV OF TECH

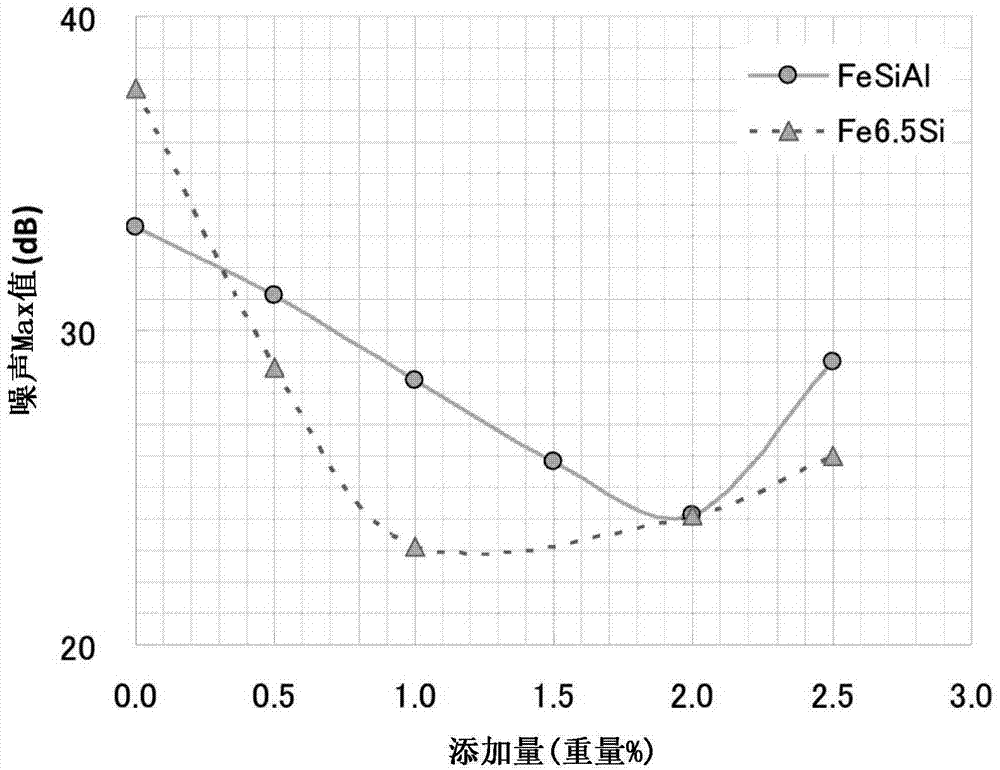

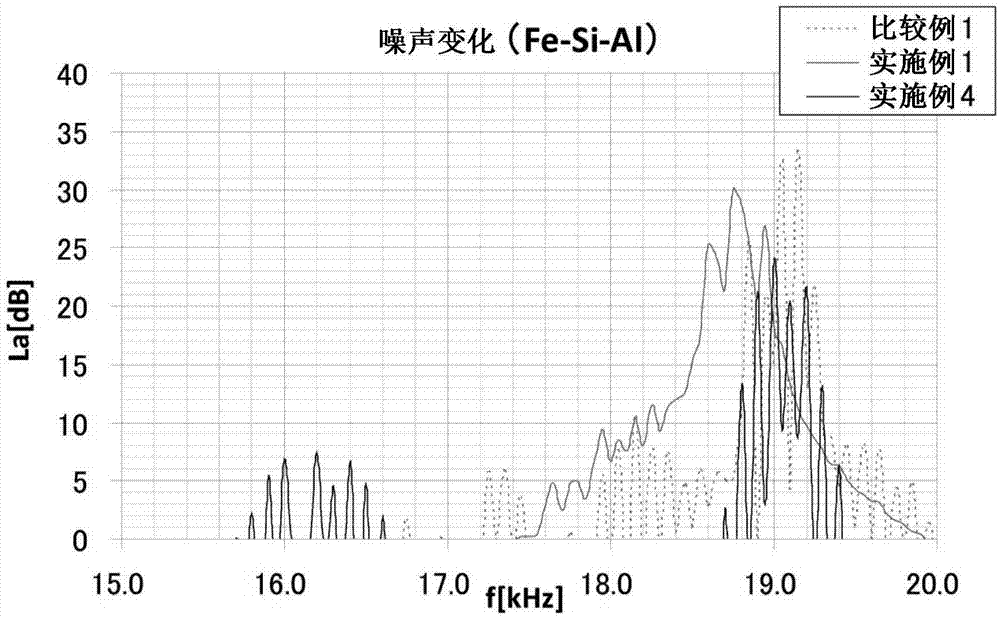

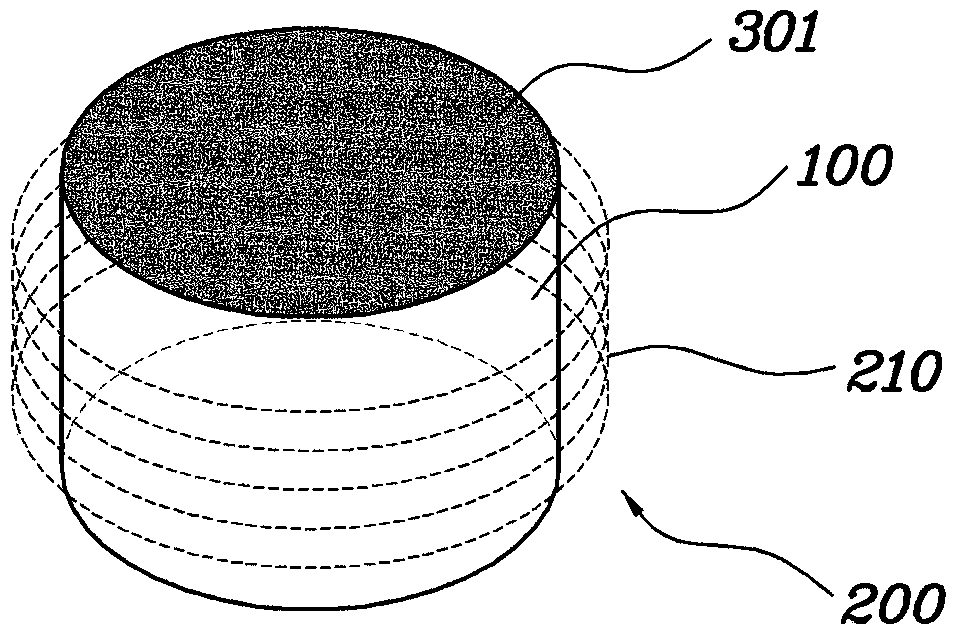

Soft magnetic powder compound, core and electric reactor

ActiveCN104217834AHigh hardnessReduce vibrationInorganic material magnetismTransformers/inductances detailsLow noiseInsulation layer

The invention provides a low-noise electric reactor, soft magnetic compound for the low-noise electric reactor and a core capable of improving hardness of an insulation layer of soft magnetic powder and effectively preventing noise. The soft magnetic powder is mixed with condensed phosphoric acid metal compounds with 0.25 wt% to 2.0 wt%, so a wrapped layer made from the condensed phosphoric acid metal compounds is formed on the periphery of the soft magnetic powder; and preferentially, condensed aluminum phosphate, especially trimerization aluminum phosphate is chosen.

Owner:TAMURA KK

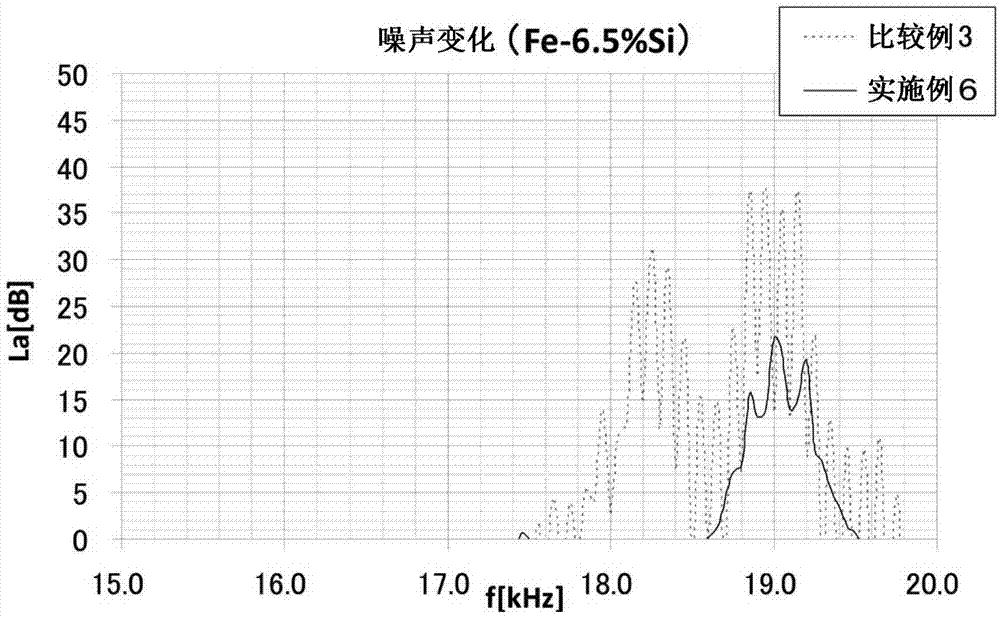

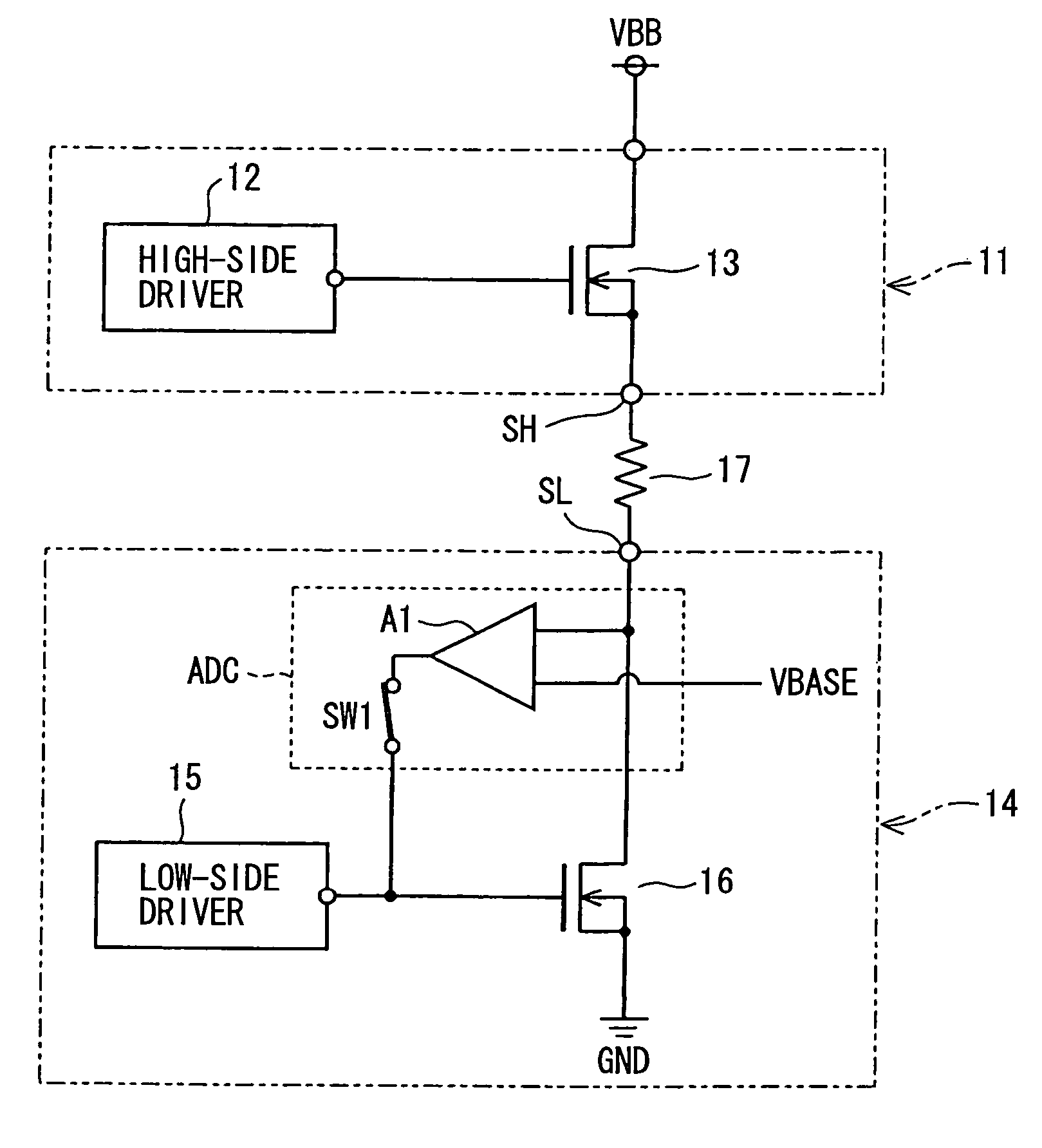

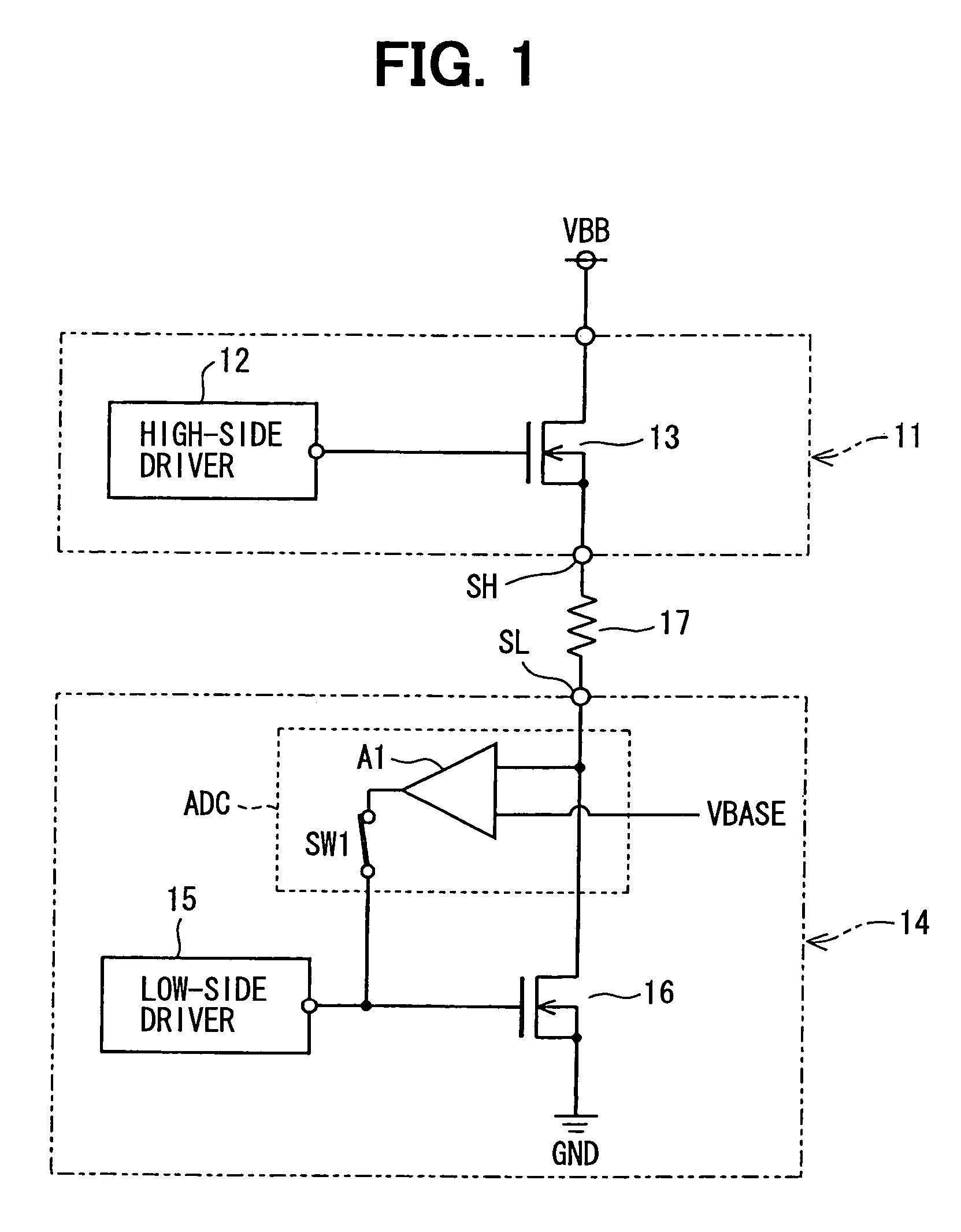

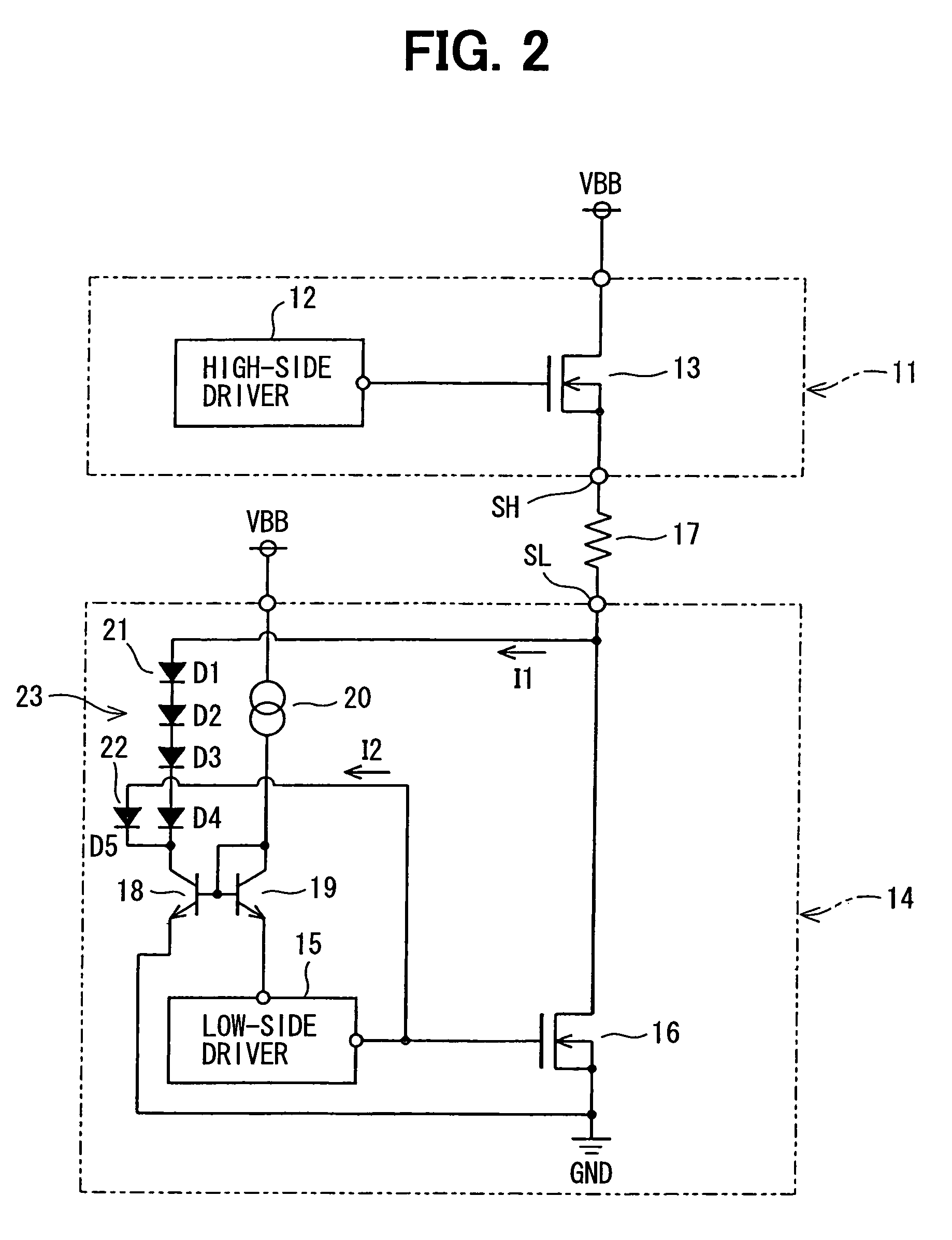

Semiconductor device for driving a load

InactiveUS7268596B2Increase in sizePrevent thermal breakdownTransistorElectric pulse generatorPower semiconductor deviceVoltage regulation

A semiconductor device for driving a load includes a first semiconductor switching element interposed between a power supply terminal and a load, a second semiconductor switching element interposed between the load and a ground terminal, a high-side driver, a low-side driver, and a voltage regulator. The voltage regulator reduces a voltage applied to a control terminal of the second switching element, when a voltage of a load terminal of the second switching element is lower than a predetermined voltage. Then, a voltage applied between the load terminal and the ground terminal of the second switching element increases, and accordingly a voltage applied between the power supply terminal and the load terminal of the first switching element decreases.

Owner:DENSO CORP

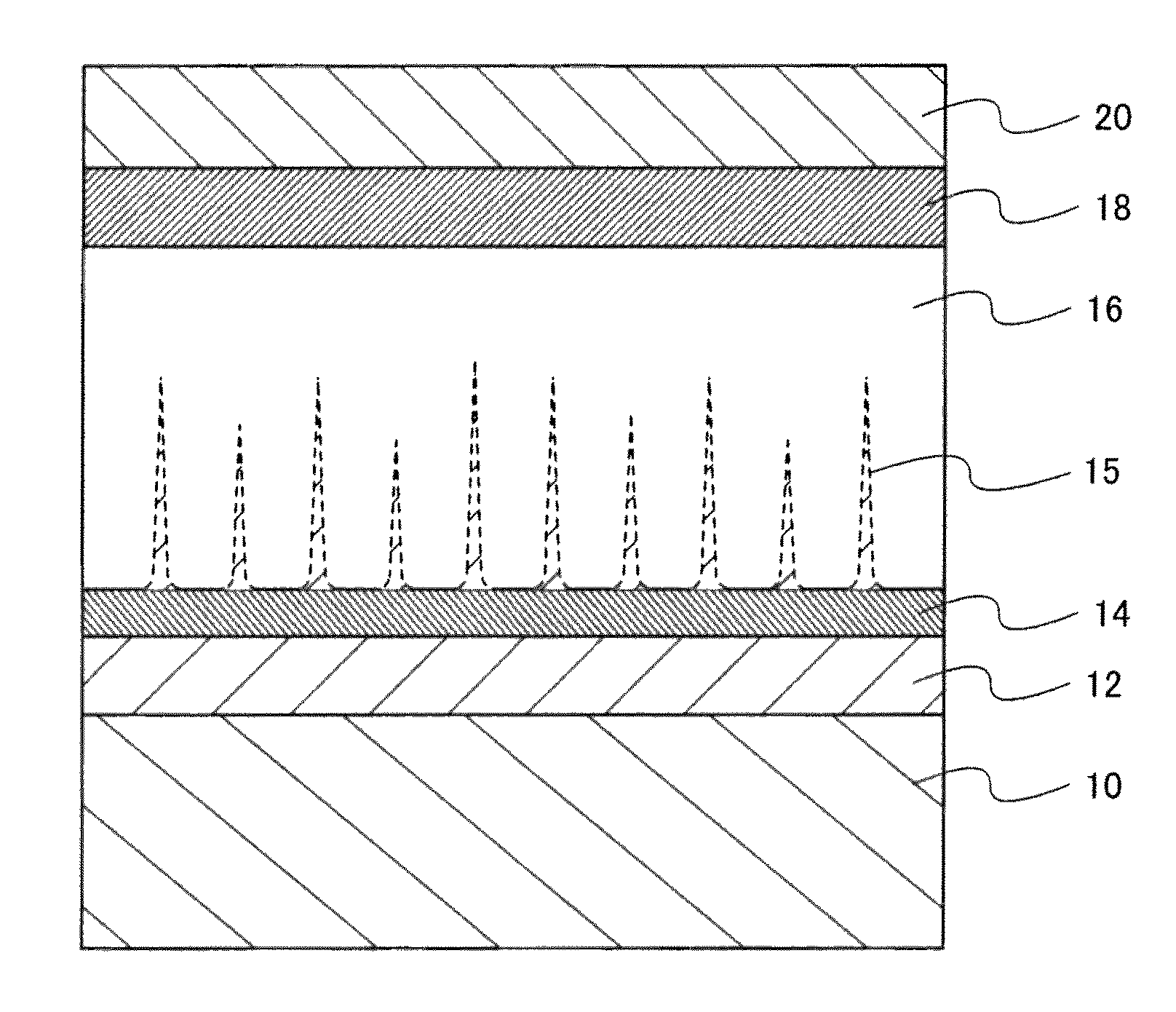

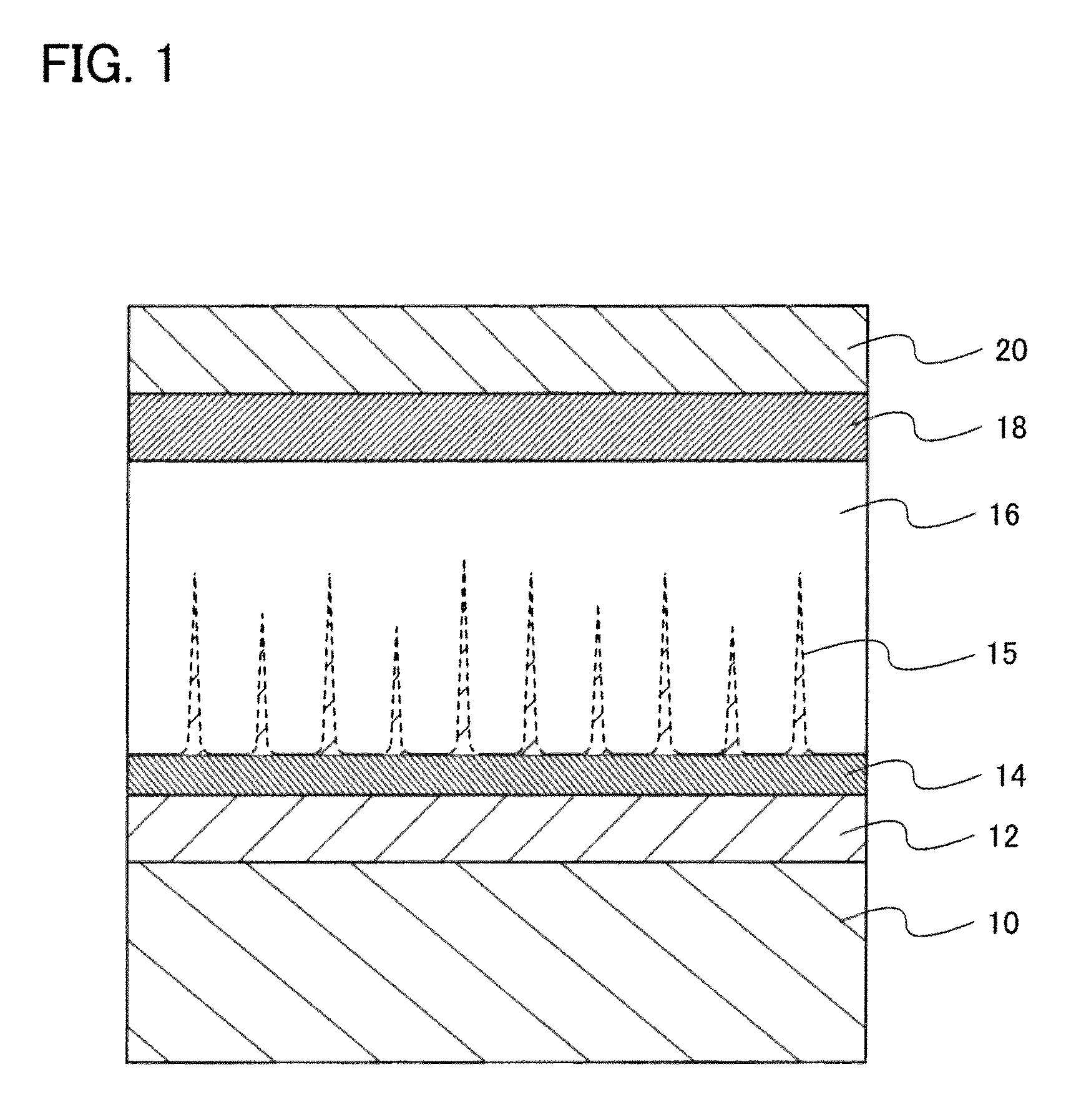

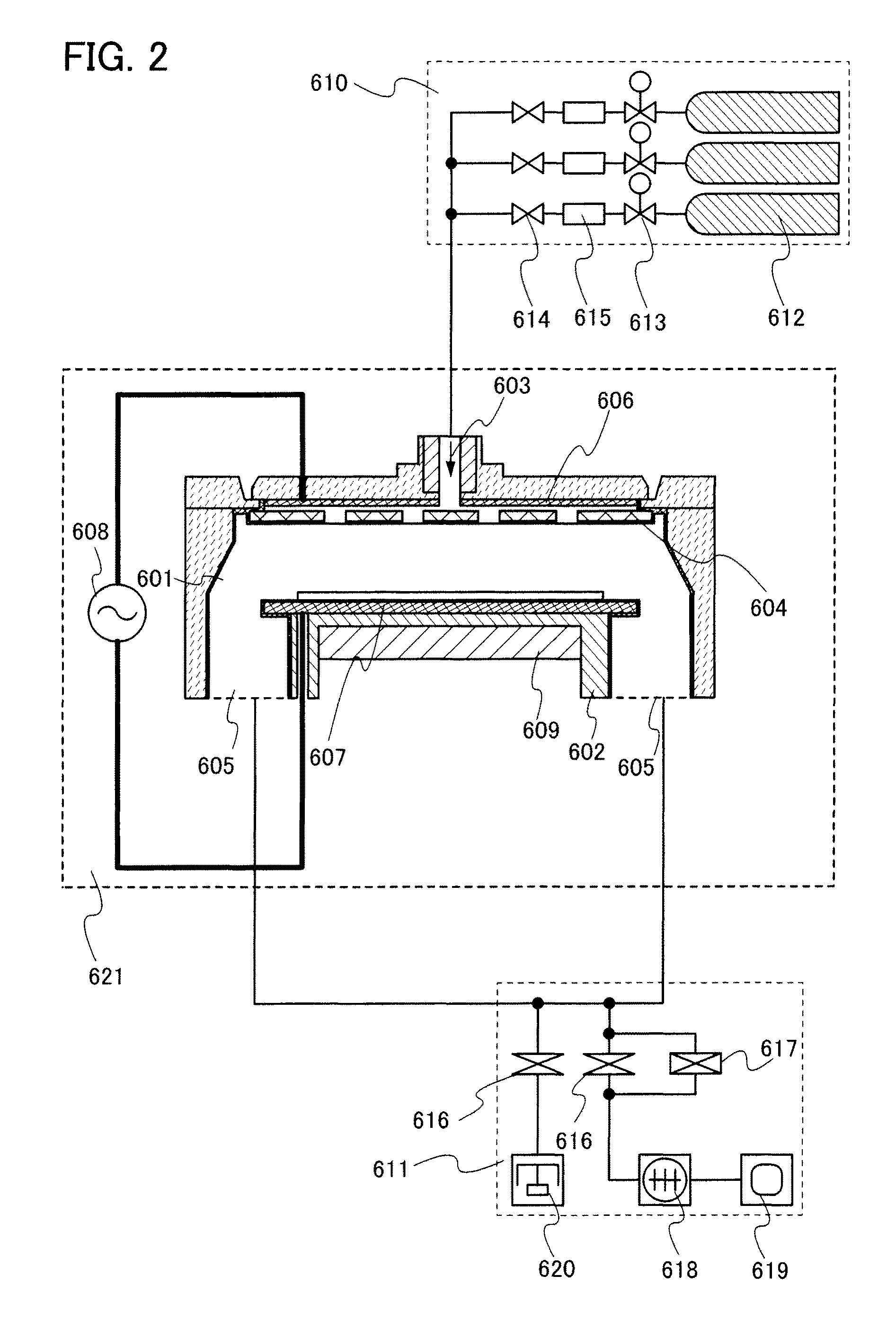

Photoelectric conversion device and method for manufacturing the same

InactiveUS7888167B2Reduce the ratioImprove cost competitivenessSemiconductor/solid-state device manufacturingCoatingsHydrogenSilanes

To provide a photoelectric conversion device with improved photoelectric conversion characteristics and cost competitiveness. A photoelectric conversion device including a semiconductor junction has a semiconductor layer in which a needle-like crystal is made to grow over an impurity semiconductor layer. The impurity semiconductor layer is formed of a microcrystalline semiconductor and includes an impurity imparting one conductivity type. An amorphous semiconductor layer is deposited on a microcrystalline semiconductor layer by setting the flow rate of a dilution gas (typically silane) to 1 time to 6 times the flow rate of a semiconductor source gas (typically hydrogen) at the time of deposition. Thus, a crystal with a three-dimensional shape tapered in a direction of the deposition of a film, i.e., in a direction from the microcrystalline semiconductor layer to the amorphous semiconductor layer is made to grow.

Owner:SEMICON ENERGY LAB CO LTD

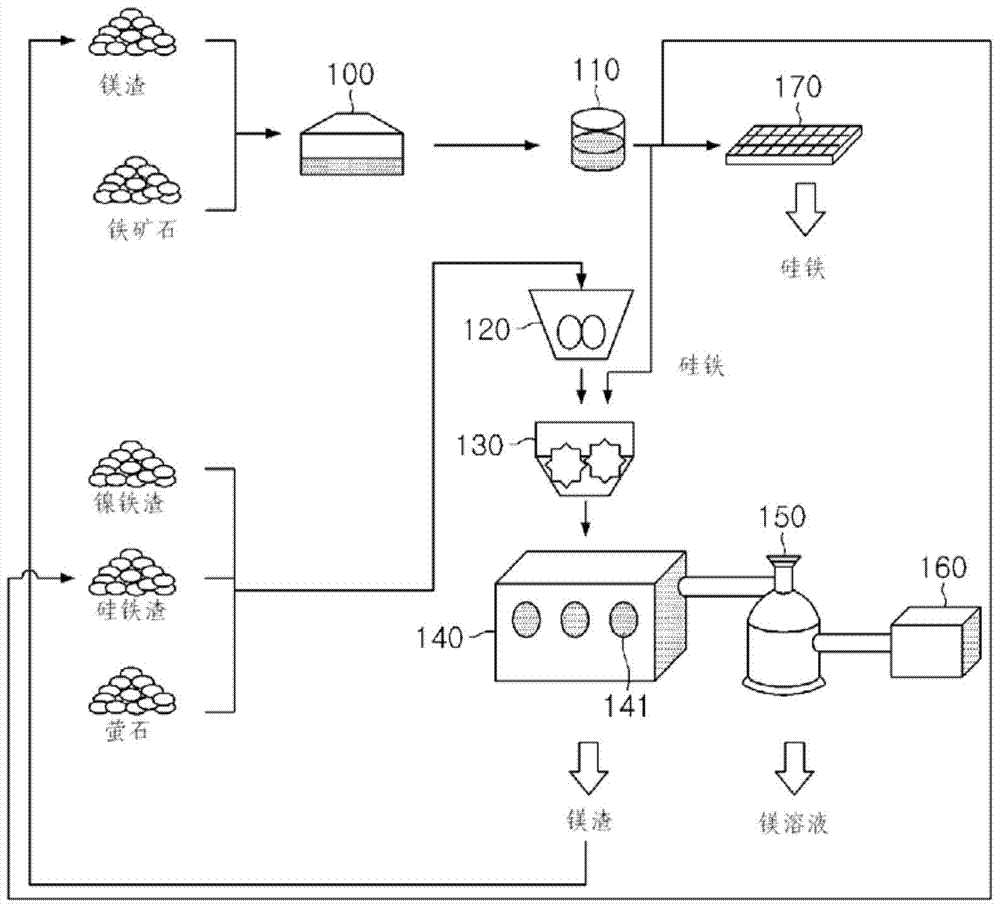

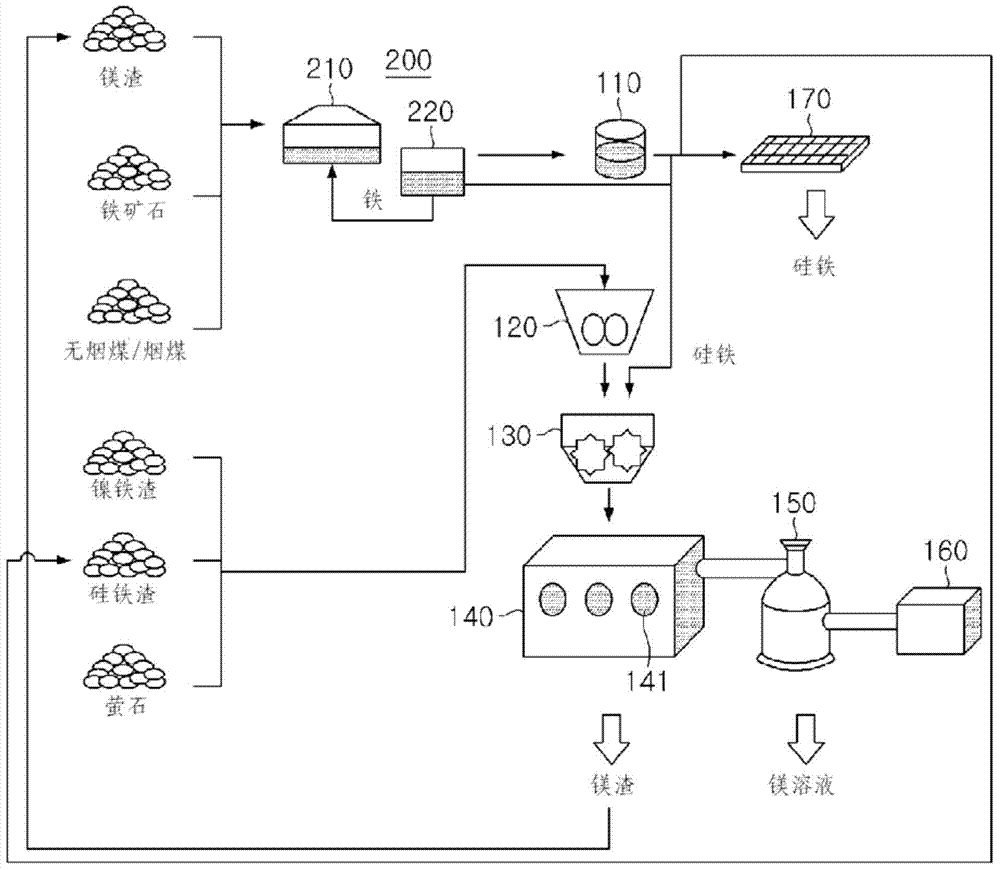

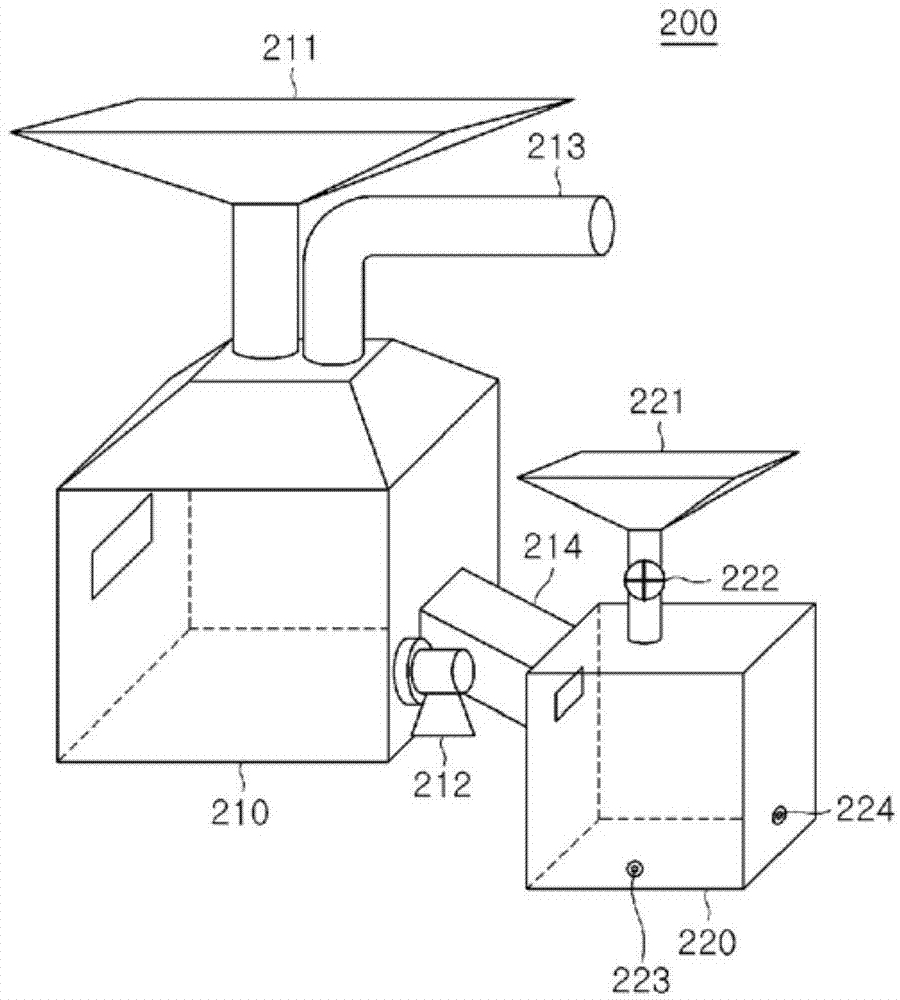

Method for preparing ferro-silicon and magnesium using ferro-nickel slag, preparation apparatus used therefor, and smelting reduction furnace

Disclosed is a method for preparing magnesium and ferro-silicon using ferro-nickel slag which is a by-product of a process for manufacturing ferro-nickel. The present invention provides a method for preparing magnesium from ferro-nickel slag, comprising the steps of: mixing a first material comprising ferro-nickel slang, ferro-silicon slag, ferro-silicon and a magnesium reduction catalyst; evaporating the mixed first material in a vacuum atmosphere of a thermal reduction furnace; and recovering magnesium evaporated in the thermal reduction furnace. In addition, provided is a method for preparing ferro-silicon from magnesium slag which is a by-product of a magnesium preparation for manufacturing a magnesium reducing agent, and preparing magnesium using ferro-silicon slag which is a by-product of a ferro-silicon preparation. According to the present invention, it is possible to resolve environmental problems by reducing energy costs and decreasing carbon monoxide discharge and recycle a resource discarded as a by-product of a process for preparing magnesium and ferro-silicon.

Owner:姜远燮

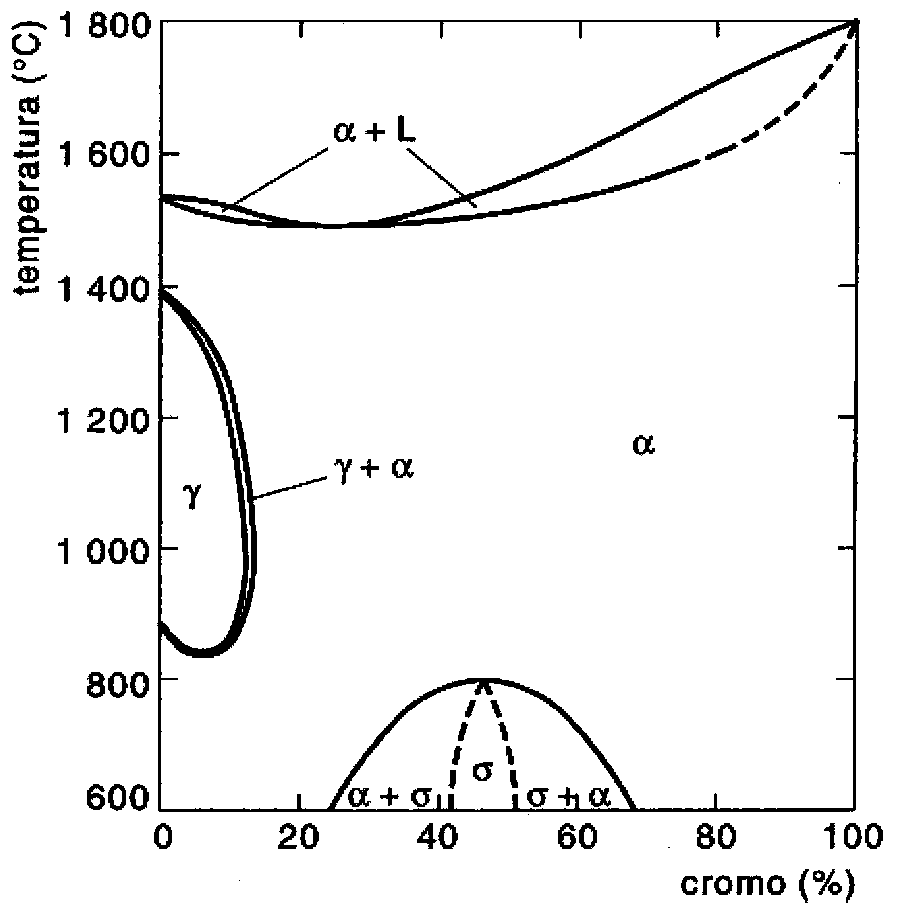

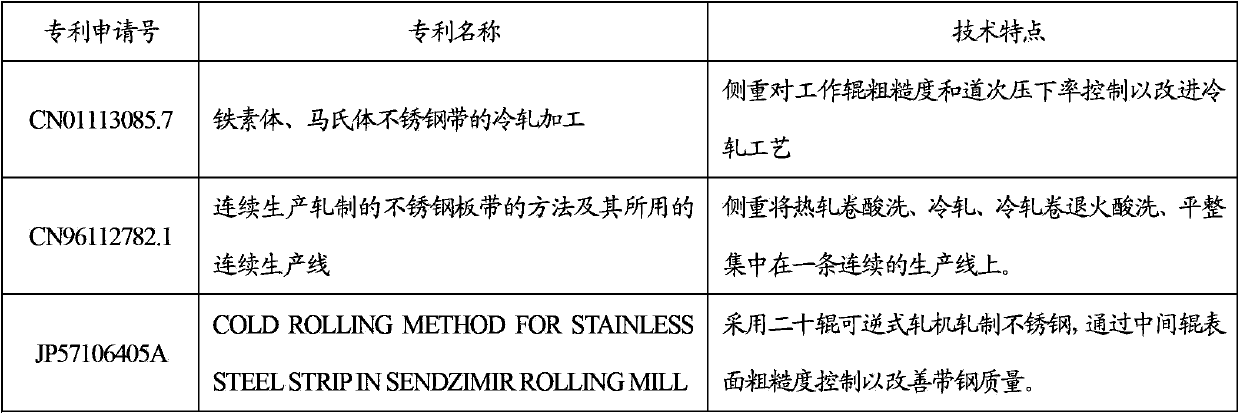

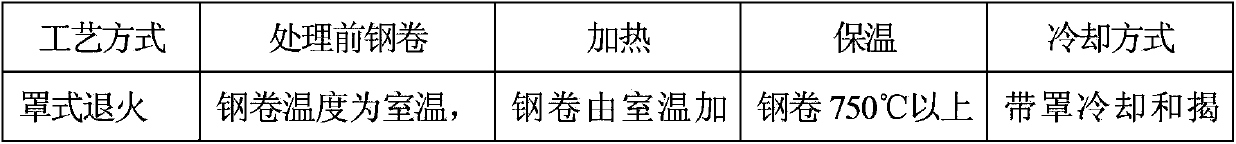

Manufacturing method for medium chrome ferrite stainless steel

InactiveCN103966409ASimplify the process flowImprove cost competitivenessRoom temperatureStrip steel

The invention provides a manufacturing method for medium chrome ferrite stainless steel. The method consists of the processes of: smelting, continuous casting, hot rolling, coiling, acid pickling, cold rolling, cold coiling annealing and pickling. In the hot rolling process, subjecting a hot rolled black coil to hot rolling at a finishing rolling temperature of 860-1000DEG C, and conducting coiling at 750-850DEG C; after coiling, subjecting the hot coil to heat preservation in a heat preservation pit directly, controlling the temperature of the hot coil sent into the heat preservation pit greater than 750DEG C, slowly cooling a steel coil at a cooling speed of less than 20DEG C / h, taking the steel coil out of the pit when the temperature of the steel coil is lower than 200DEG C, and performing air cooling to room temperature; subjecting the hot rolled black coil to acid pickling directly on a continuous acid pickling line, and removing the surface oxide scale; after acid pickling, conducting cold rolling on the steel coil; carrying out recrystallization and continuous annealing on cold-rolled strip steel; and performing acid pickling to remove the surface oxide scale, and at the same time conducting passivation treatment on the strip steel. The method provided by the invention omits the process of hot coil bell-type furnace annealing, simplifies the process flow, and strengthens the cost competitiveness. Compared with single-stand reversible rolling, cold continuous rolling has the advantages of high production efficiency and low cost.

Owner:BAOSTEEL STAINLESS STEEL

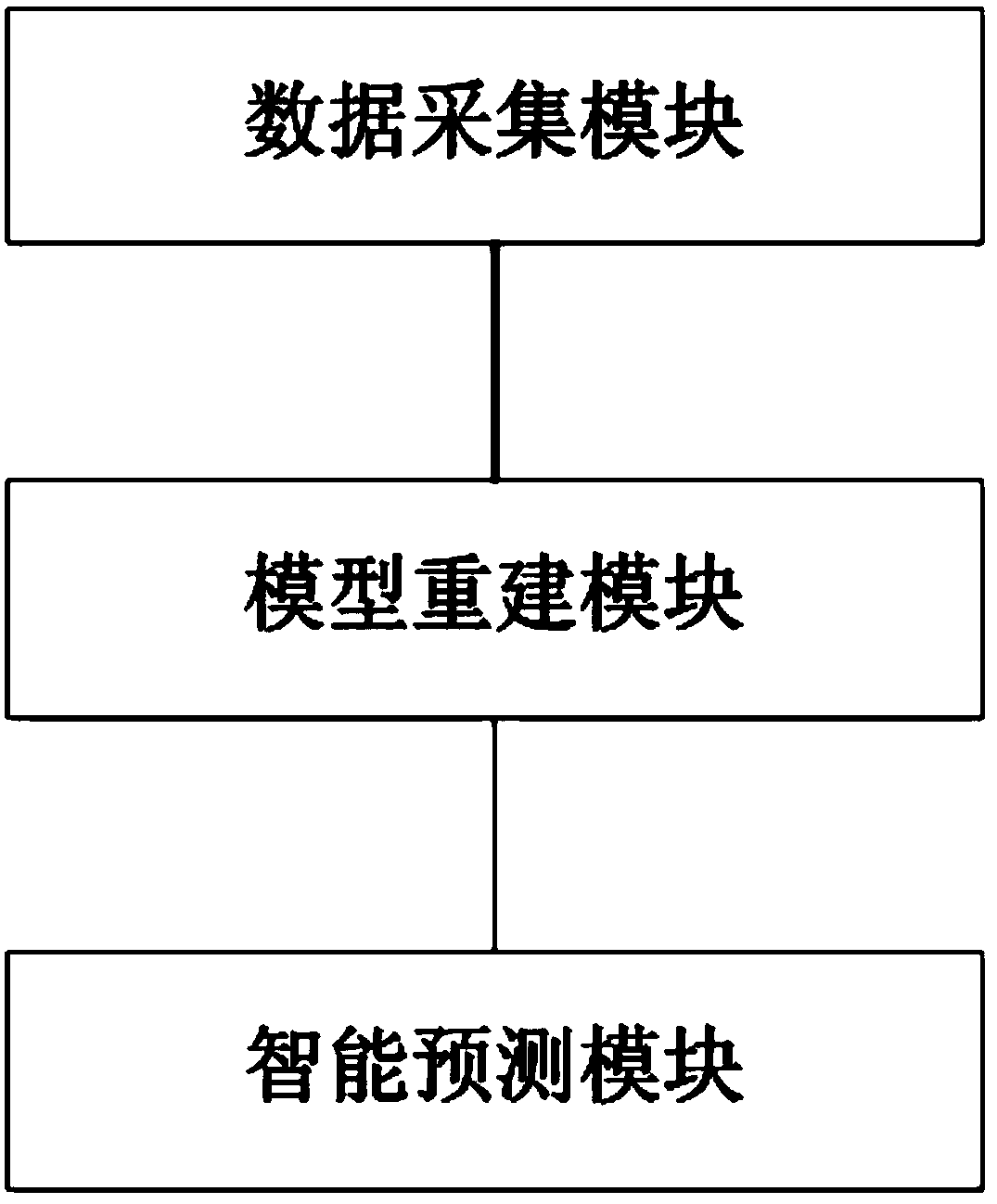

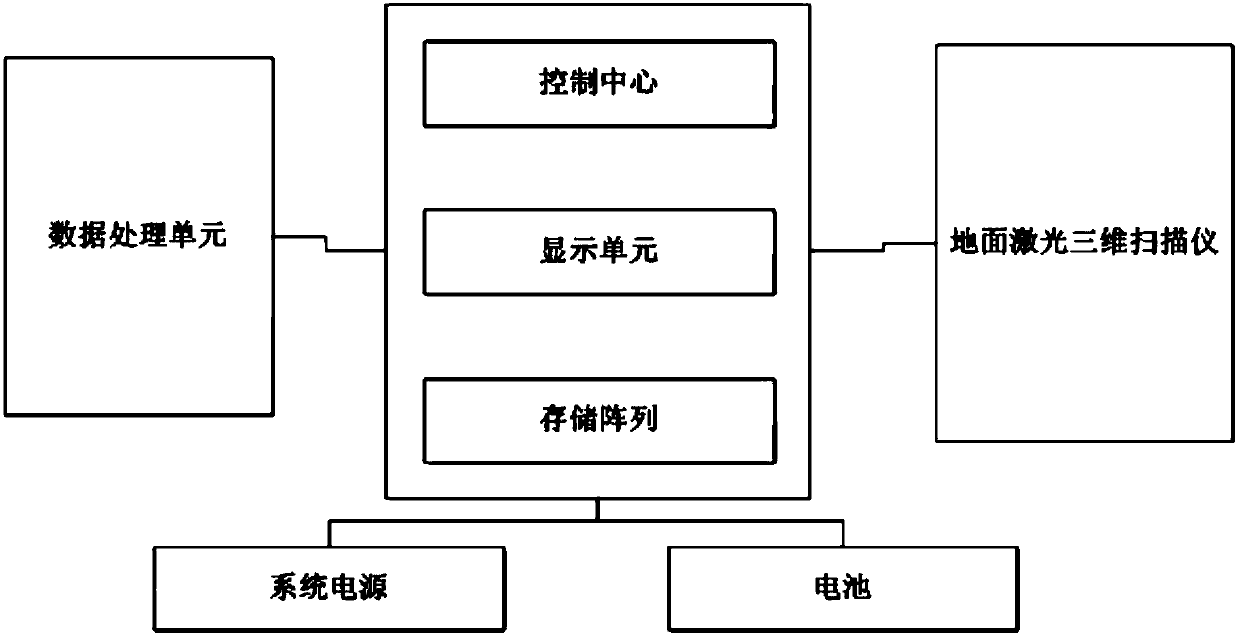

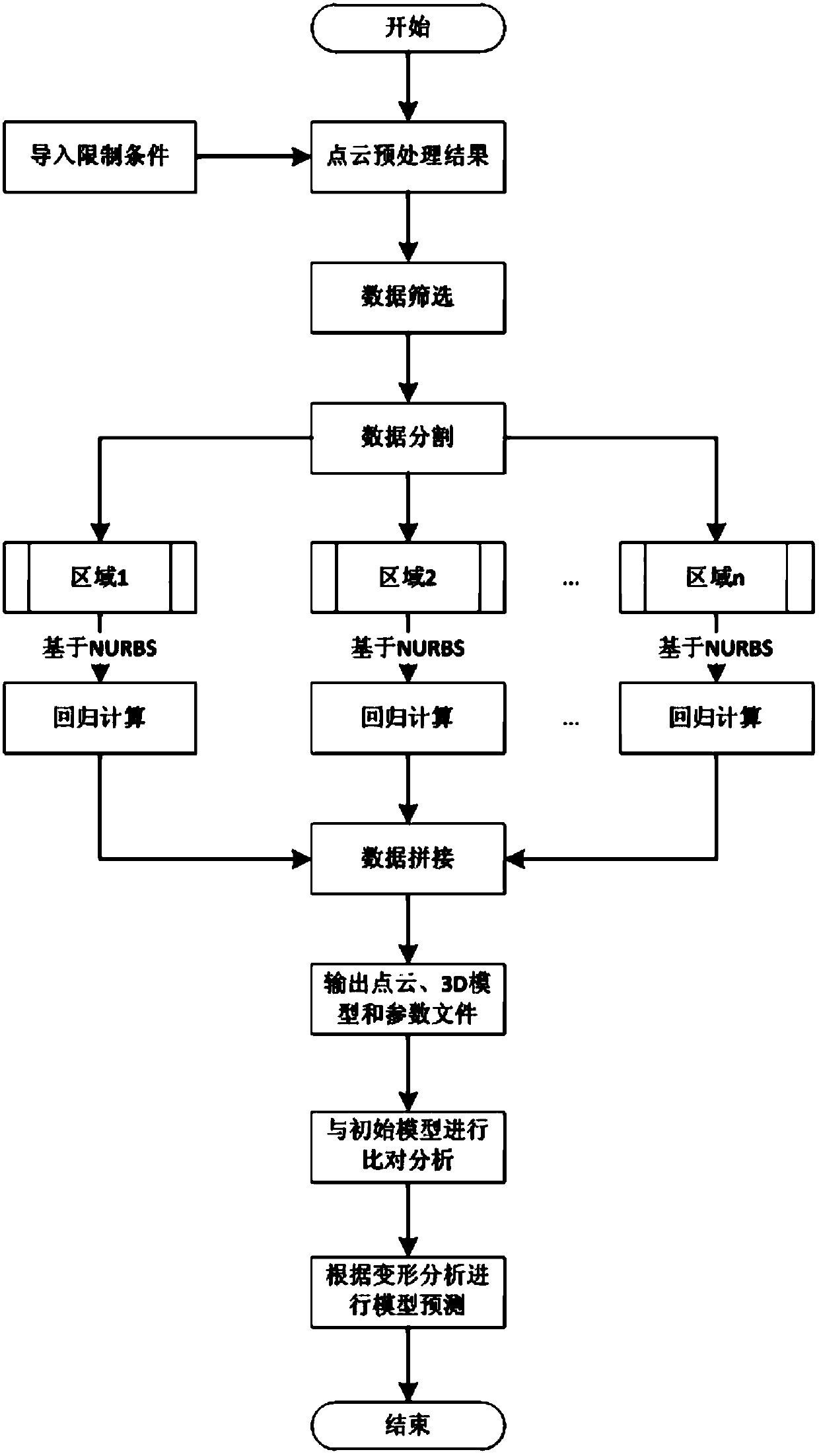

Component defect monitoring and prediction system based on TLS (Terrestrial Laser Scanning)

InactiveCN107729582AEasy to operateEasy to readDesign optimisation/simulationSpecial data processing applicationsPattern recognitionElement model

The application provides a structure health monitoring and intelligent-prediction method based on TLS (Terrestrial Laser Scanning) technology. The method includes: acquiring point cloud data of each area of an external structure of a component, and preprocessing the obtained point cloud data; further processing the point cloud data to obtain a complete three-dimensional model and deformation and crack data, and then carrying out finite-element analysis on the initial model to obtain material deformation and crack results; reconstructing a finite-element model according to corrected parameters,analyzing structure deformation and crack situations, and comparing the deformation and crack results of the finite-element model with the point cloud data to obtain a numerical-value comparison result; and utilizing the reconstructed finite-element model to intelligently predict future deformation situations of the structure, carrying out risk analysis, and giving a risk analysis report. According to the method, detection time of the external structure of the component can be shortened, and accuracy of a defect change trend of the component can be improved.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG

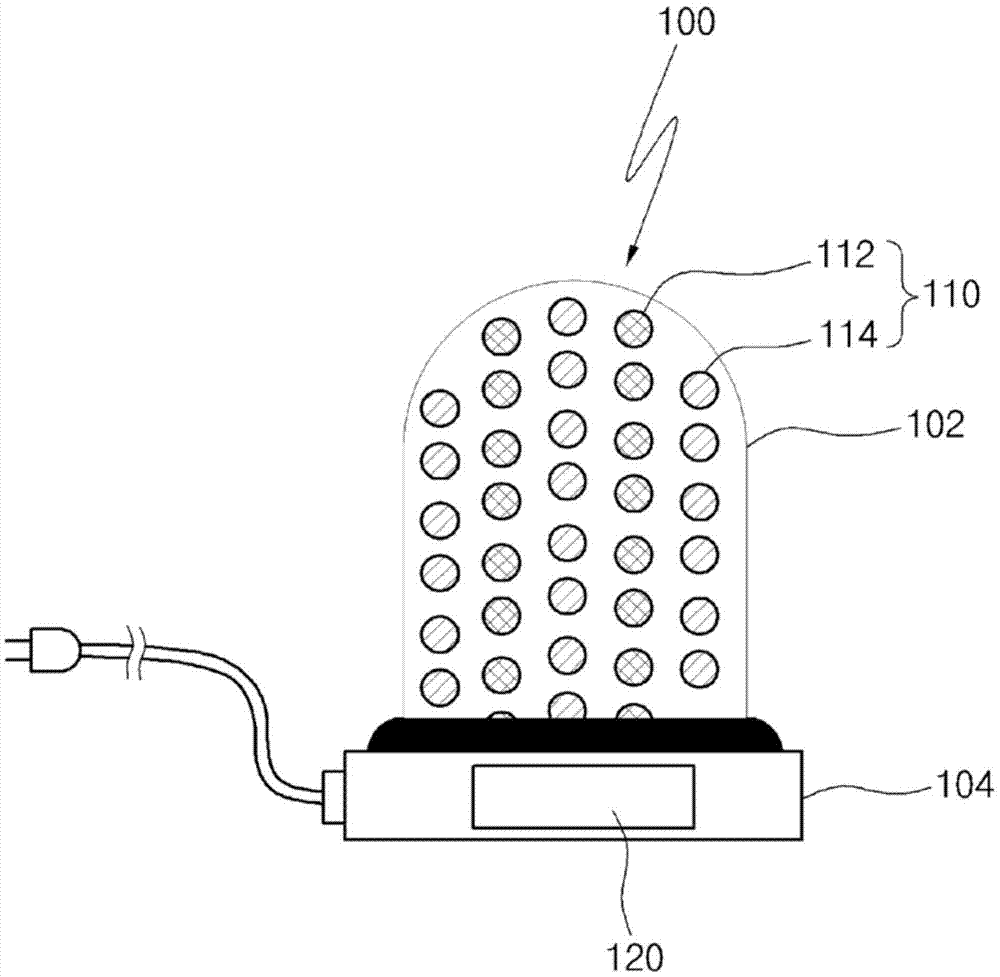

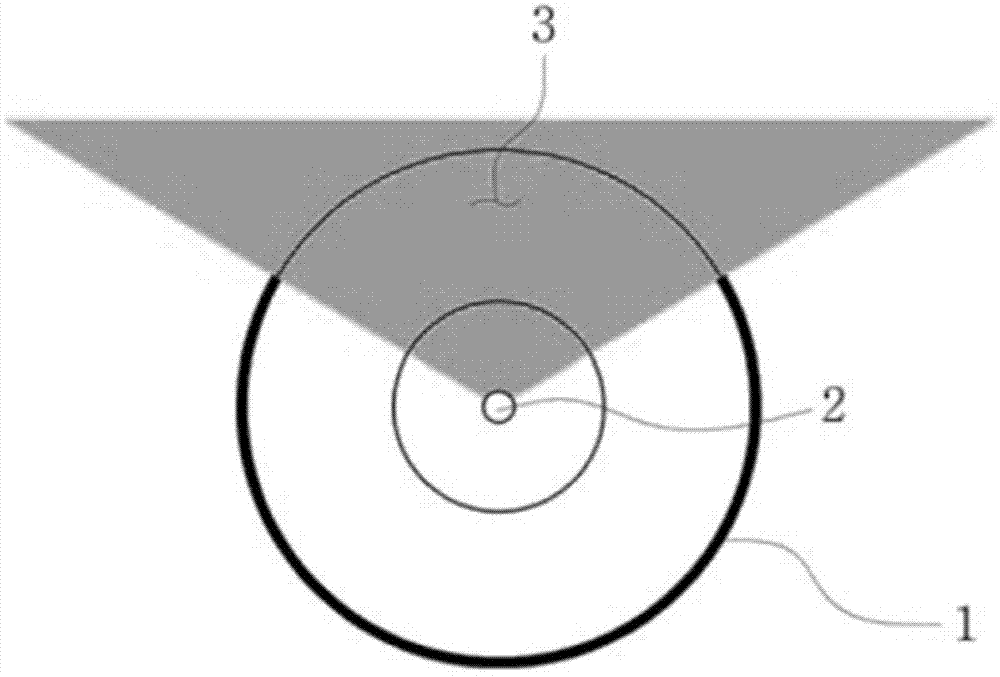

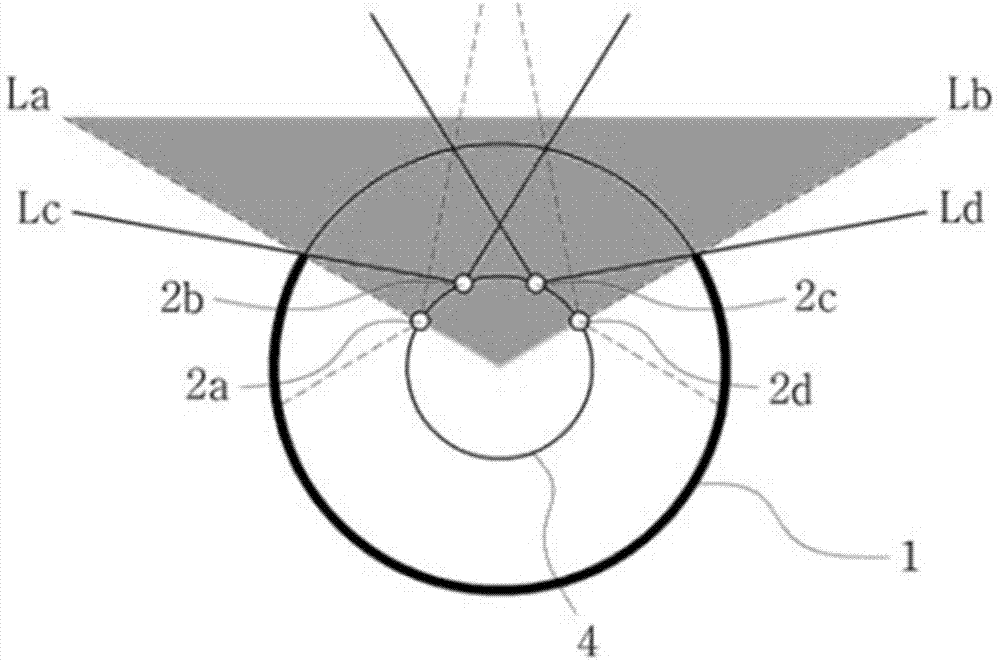

Marine led navigation lights

ActiveCN103697370AAvoid collisionStrong impact resistanceLighting applicationsNon-electric lightingComputer moduleEngineering

The invention provides marine LED navigation lights which performs primary restriction on angle of light emitted from an LED through forming a shielding component by LED modules and performs secondary restriction on angle of the light emitted from the LED through forming a locking part at a housing, so that collision between ships can be prevented without breaking through International Regulations for Preventing Collisions at sea. Furthermore the invention provides the marine LED navigation lights which have advantages of high impact resistance, long service life, remarkable power and maintenance cost reduction and cost competitiveness improvement through replacing existing incandescent lamps by LEDs. The marine LED navigation lights provided by the invention comprise the components of: a housing which accepts a main board in the internal space; a plurality of LED modules which are arranged on a main substrate and is provided with a plurality of LEDs for emitting light; and a cover which covers the upper part of the housing, wherein the LED module comprises the following components: a heat radiating board which is internally provided with a central hole; LEDs which are formed outside the heat radiating board and are used for emitting light; and heat radiating fins which are formed in the central hole of the heat radiating board and are used for radiating heat transmitted from the LEDs.

Owner:KUK DONG ELECOM

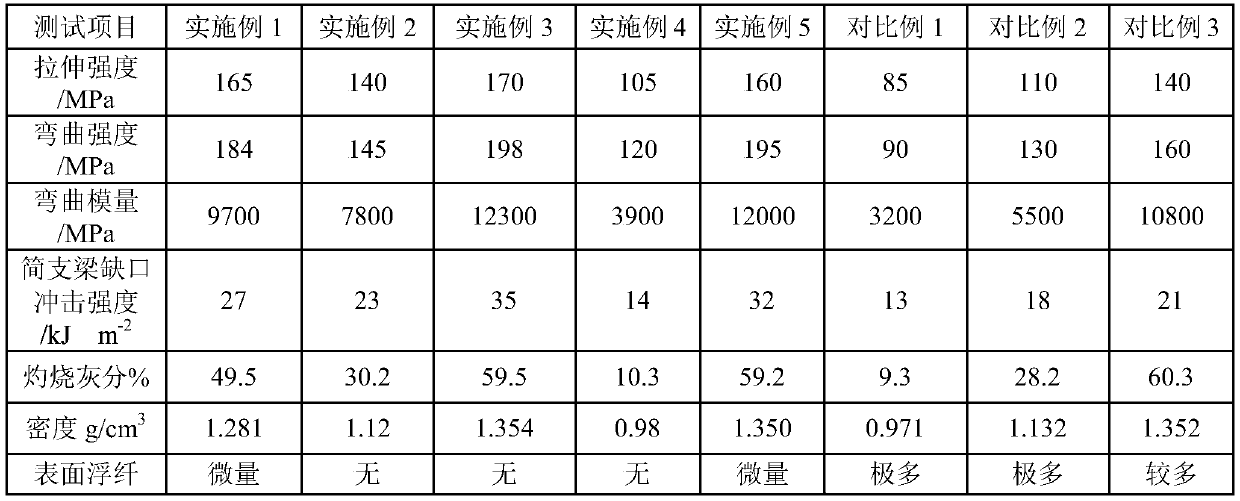

Long glass fiber enhanced polypropylene composite material and preparation method thereof

The invention relates to the technical field of polypropylene materials, and specifically relates to a long glass fiber enhanced polypropylene composite material and a preparation method thereof. Thelong glass fiber enhanced polypropylene composite material comprises a component A and a component B. The component A is prepared from following components in parts by weight: 30 to 90 parts of polypropylene resin, 10 to 60 parts of alkali-free continuous glass fibers, 0.5 to 2.0 parts of a lubricant, 0.01 to 0.1 part of peroxides, 0.5 to 3.0 parts of a silane coupling agent, and 0.2 to 0.7 part of an antioxidant. The component B is prepared from following components in parts by weight: 30 to 90 parts of polypropylene resin, 10 to 60 parts of alkali-free continuous glass fibers, 0.5 to 2.0 parts of a lubricant, 1.0 to 4.0 parts of a catalyst, 0.01 to 0.1 part of peroxides, and 0.2 to 0.7 part of an antioxidant. Peroxides decompose and functionalize polypropylene; during the infiltration process, polypropylene has high fluidity and excellent infiltration effect; after the material is moulded, the mechanical strength of the material is improved, and moreover, the prepared material has few fibers on the surface, is easy to mould, and has a high performance.

Owner:QINGDAO HAIER NEW MATERIAL R&D CO LTD

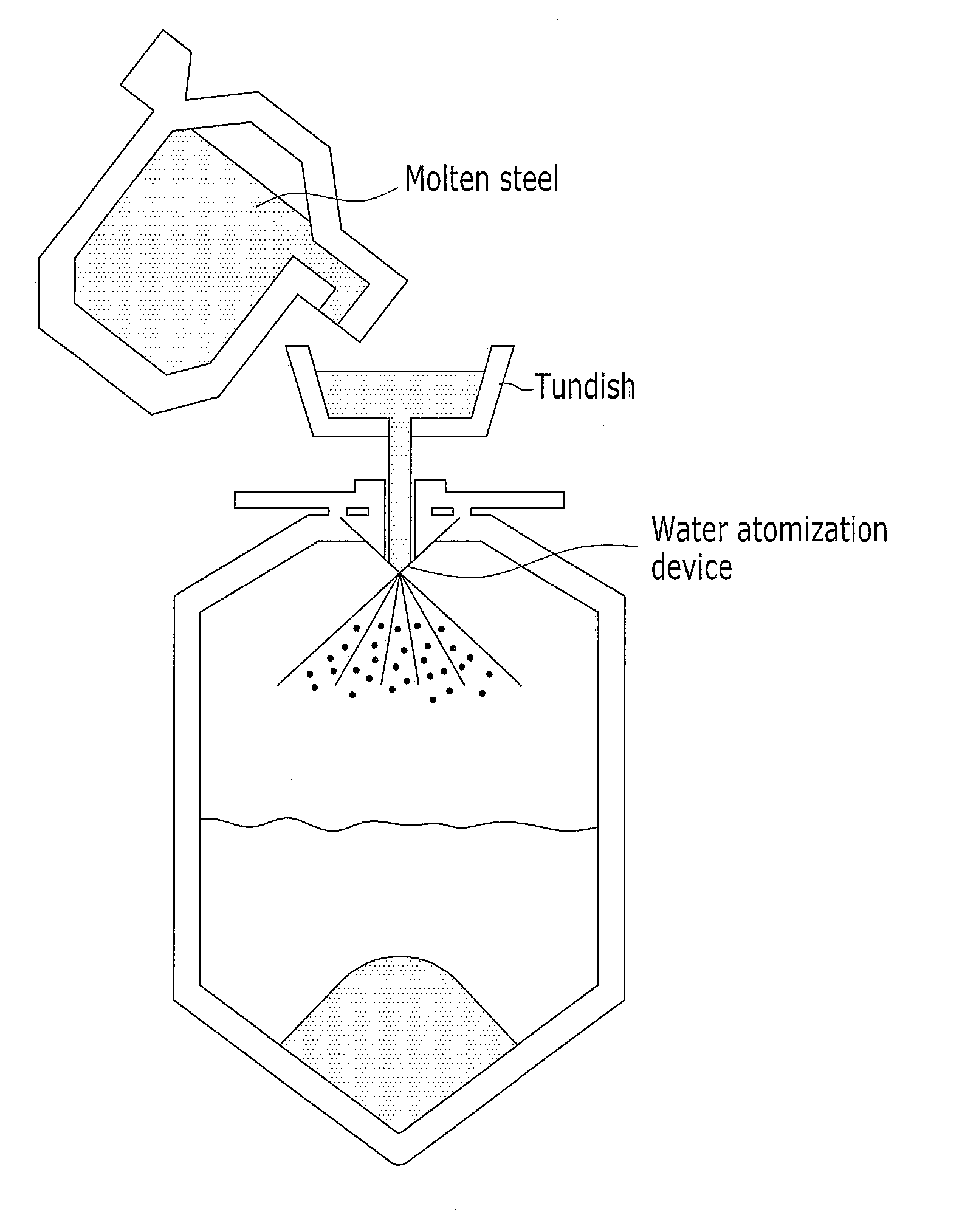

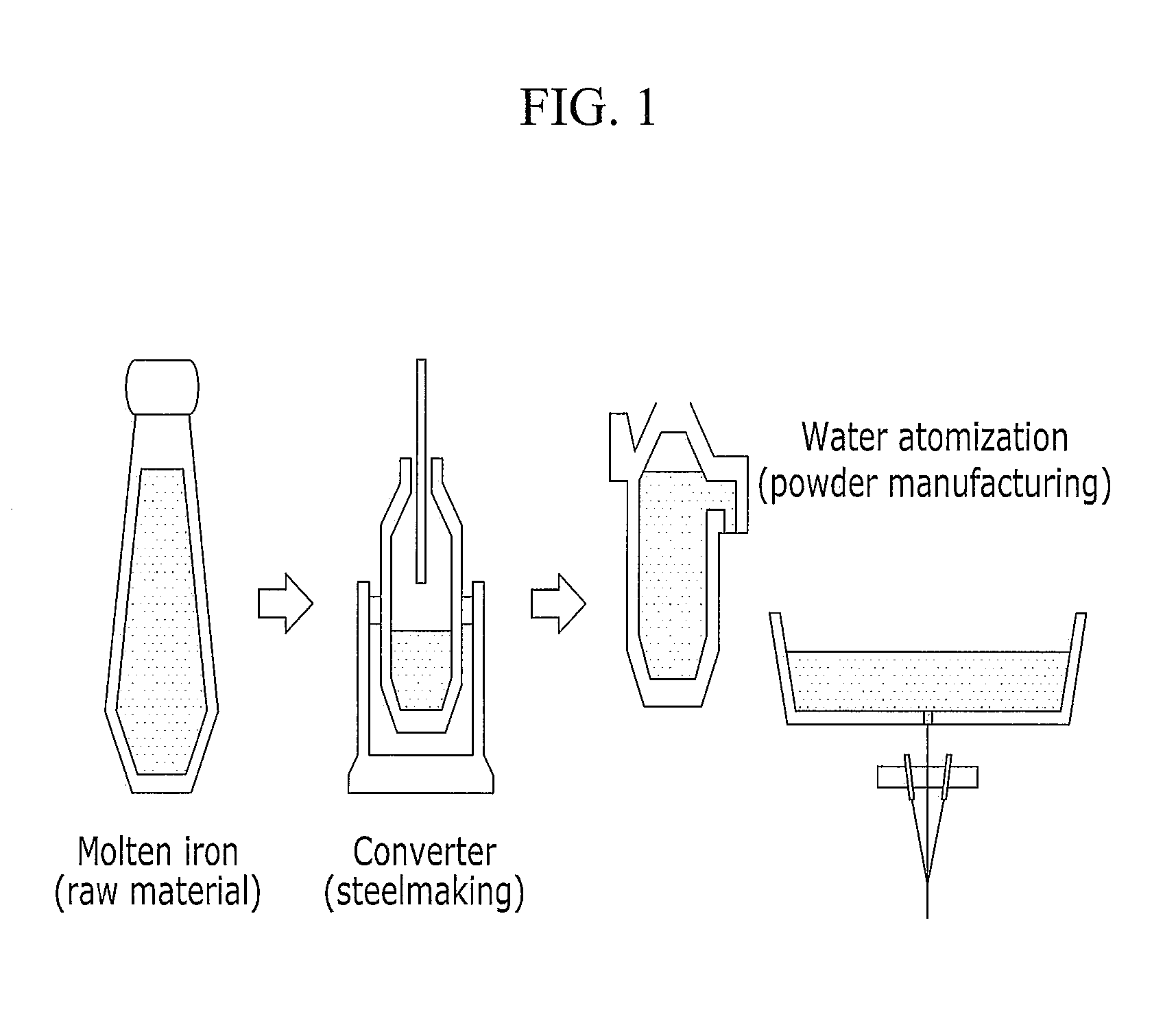

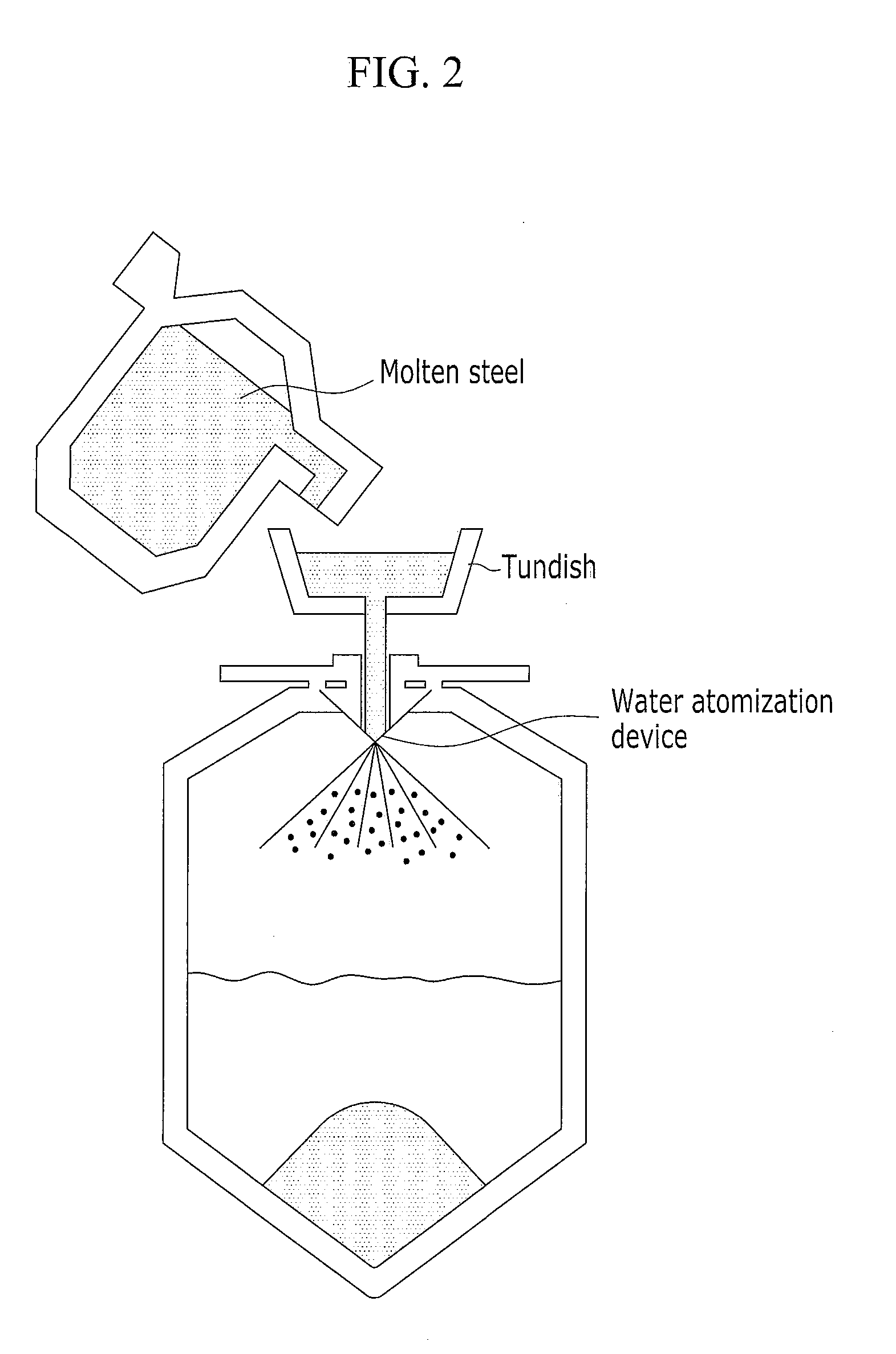

Method of Manufacturing Iron-Based Powder

ActiveUS20130180360A1Quality improvementReduce manufacturing costManufacturing convertersProcess efficiency improvementSteelmakingPre treatment

A method of manufacturing iron-based powder includes providing an iron-based molten steel manufactured through a iron making process and a steelmaking process to a tundish; and performing water atomization over the molten steel discharged through a nozzle connected to the tundish. The iron-based powder is manufactured from the molten steel refined after a molten iron tapped from a iron making process is charged into a converter without a pre-treatment process of the molten iron, thus economically providing the highly clean iron-based powder.

Owner:RES INST OF IND SCI & TECH +1

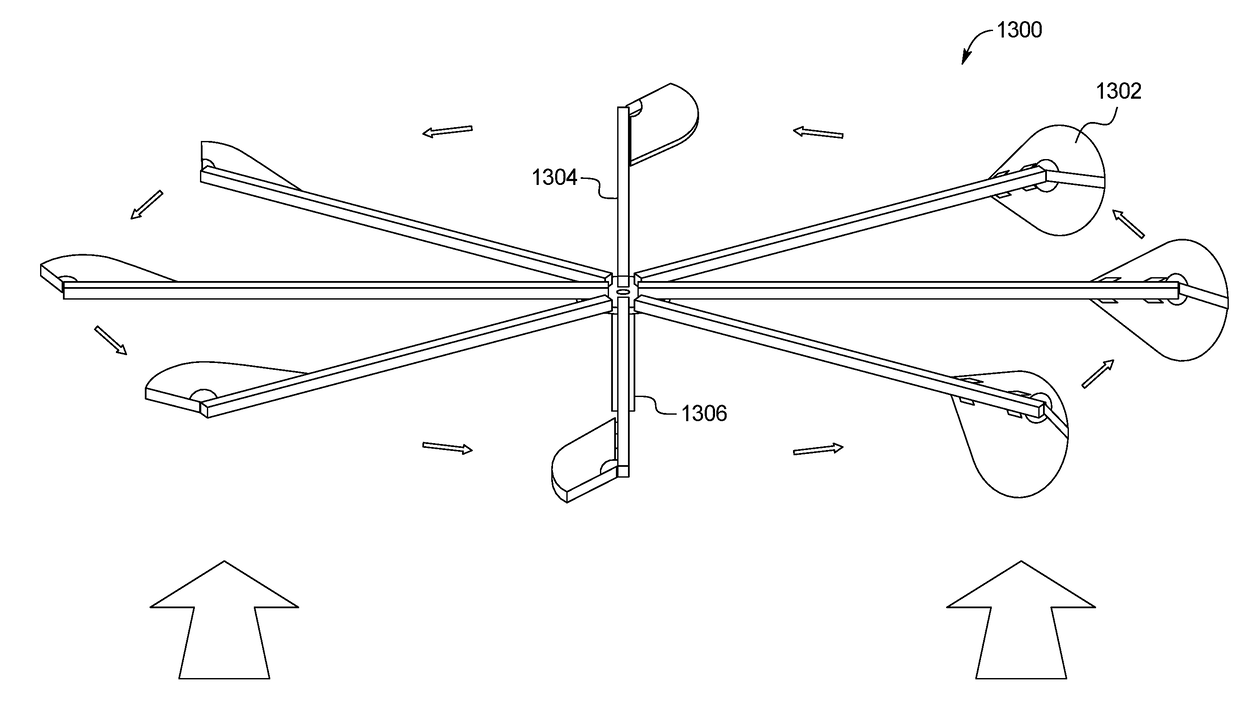

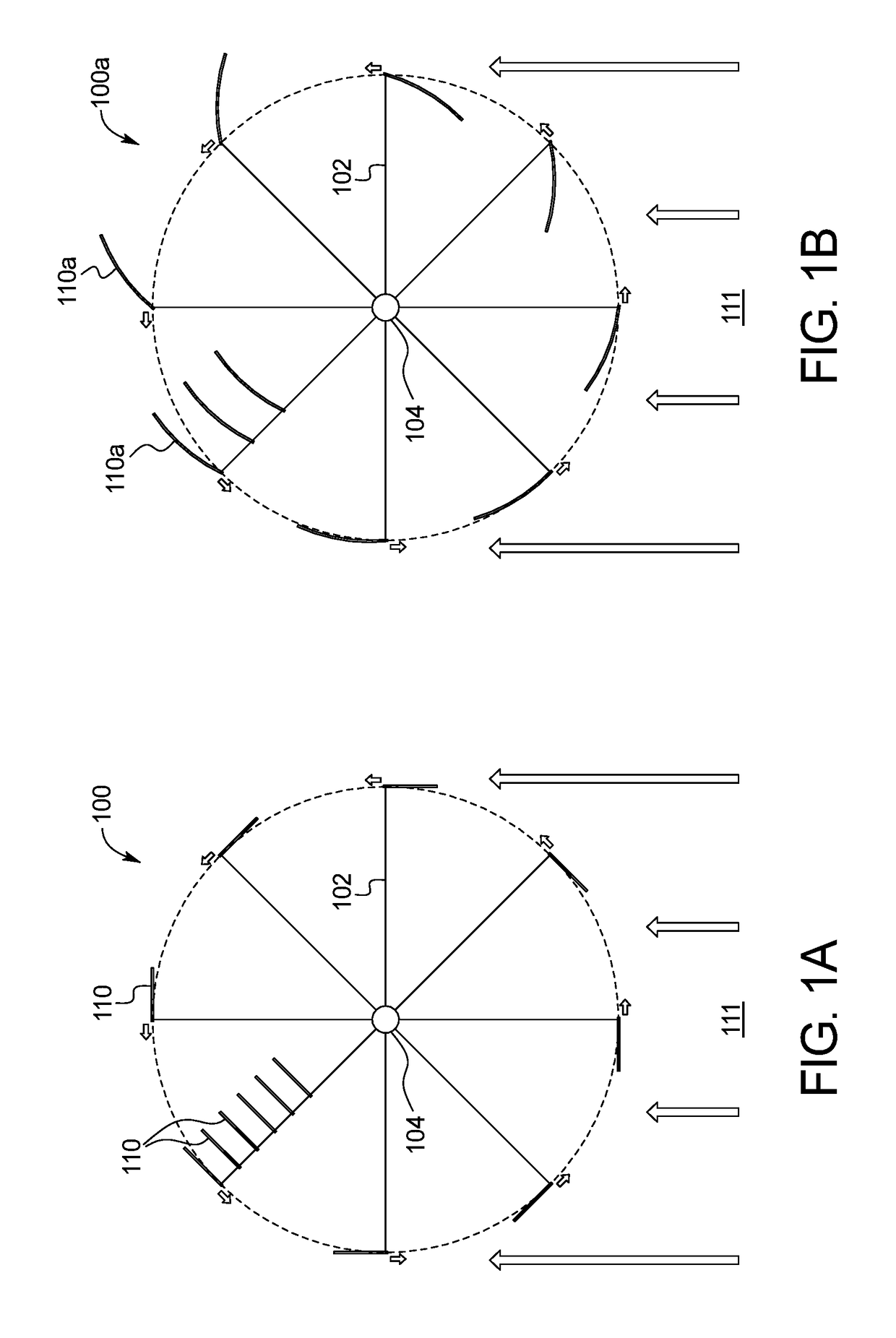

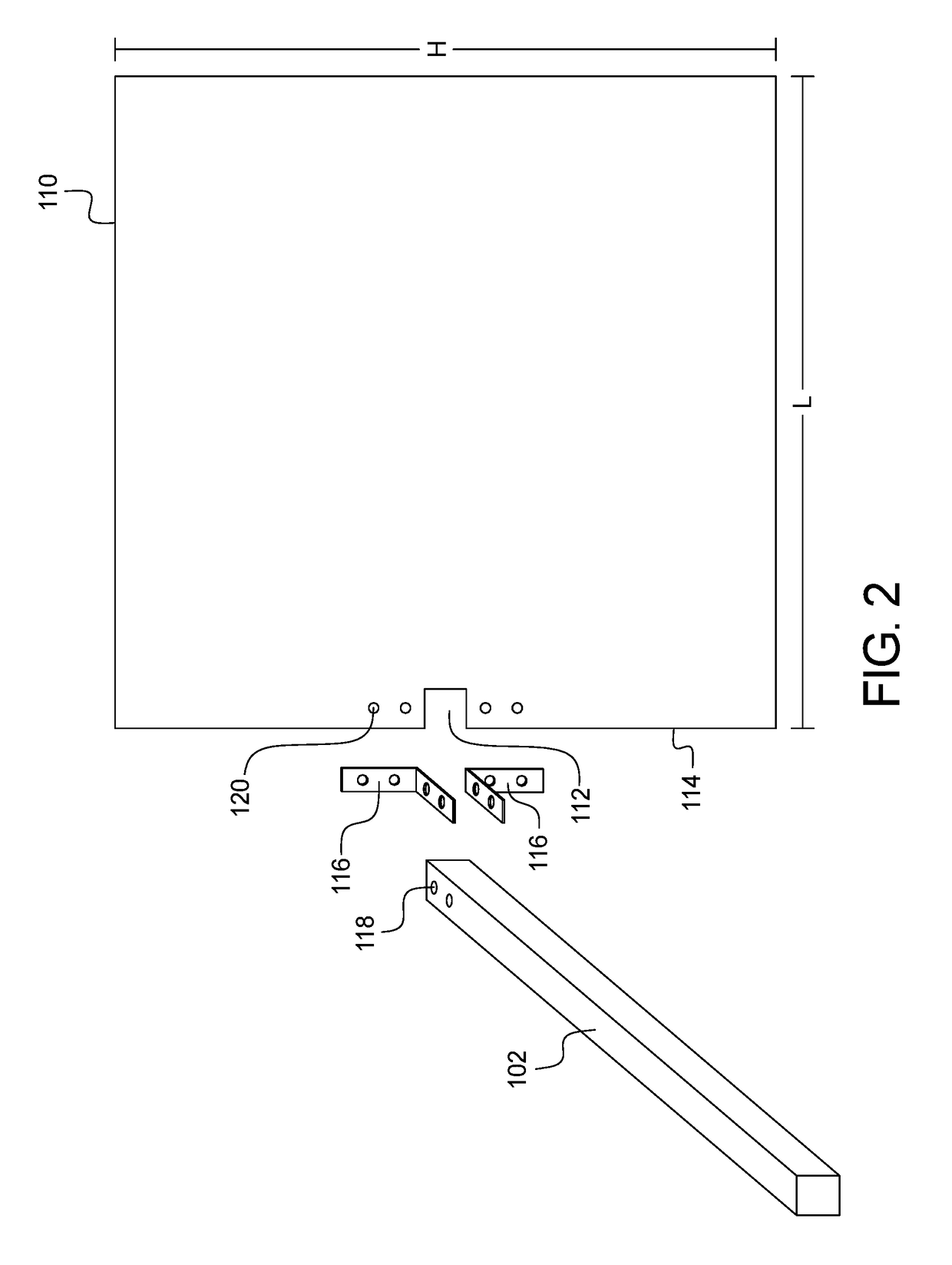

Flexible Wind Turbine Apparatus

InactiveUS20170211544A1Little no disturbanceImprove cost competitivenessRenewable energy generationMachines/enginesArcuate shapeTurbine

An airfoil for a wind turbine apparatus includes an airfoil body having an arcuate shape extending between a first end and a second end and an airfoil support secured to a midpoint on the airfoil body and connected to the outer end of the support arm. The airfoil body includes a first portion adjacent to the first end and a second portion adjacent to the second end. The first end and the second end are secured to the support arm, and the body of the airfoil is comprised of material capable of flexing in response to wind pressure. The first and second portions of the airfoil body extend away from each other in an extended position and collapse together in a collapsed position, and the orientation of the airfoil relative to the direction of the wind causes the airfoil to move between the open and closed positions.

Owner:OLIVERA REINALDO IVAN

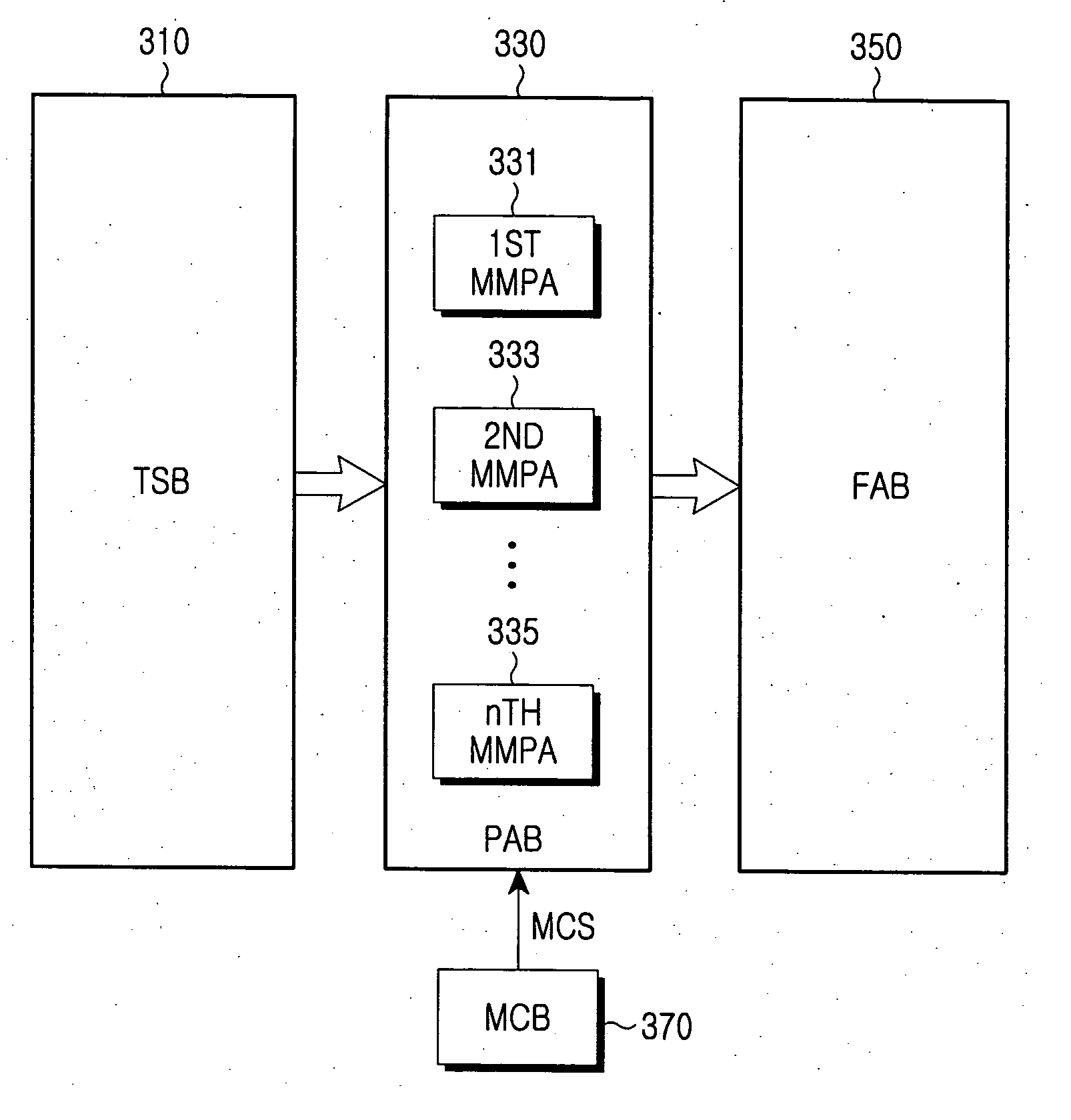

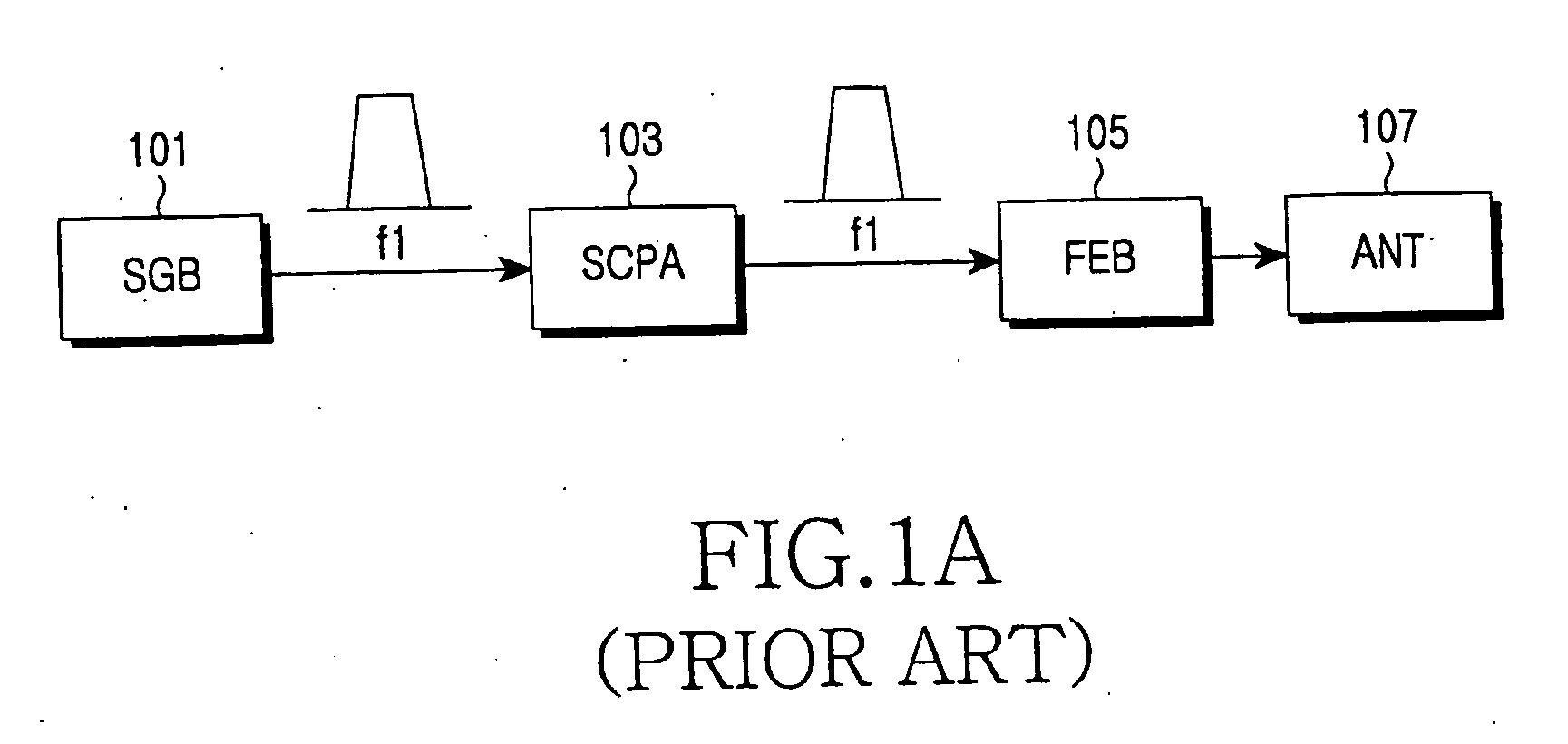

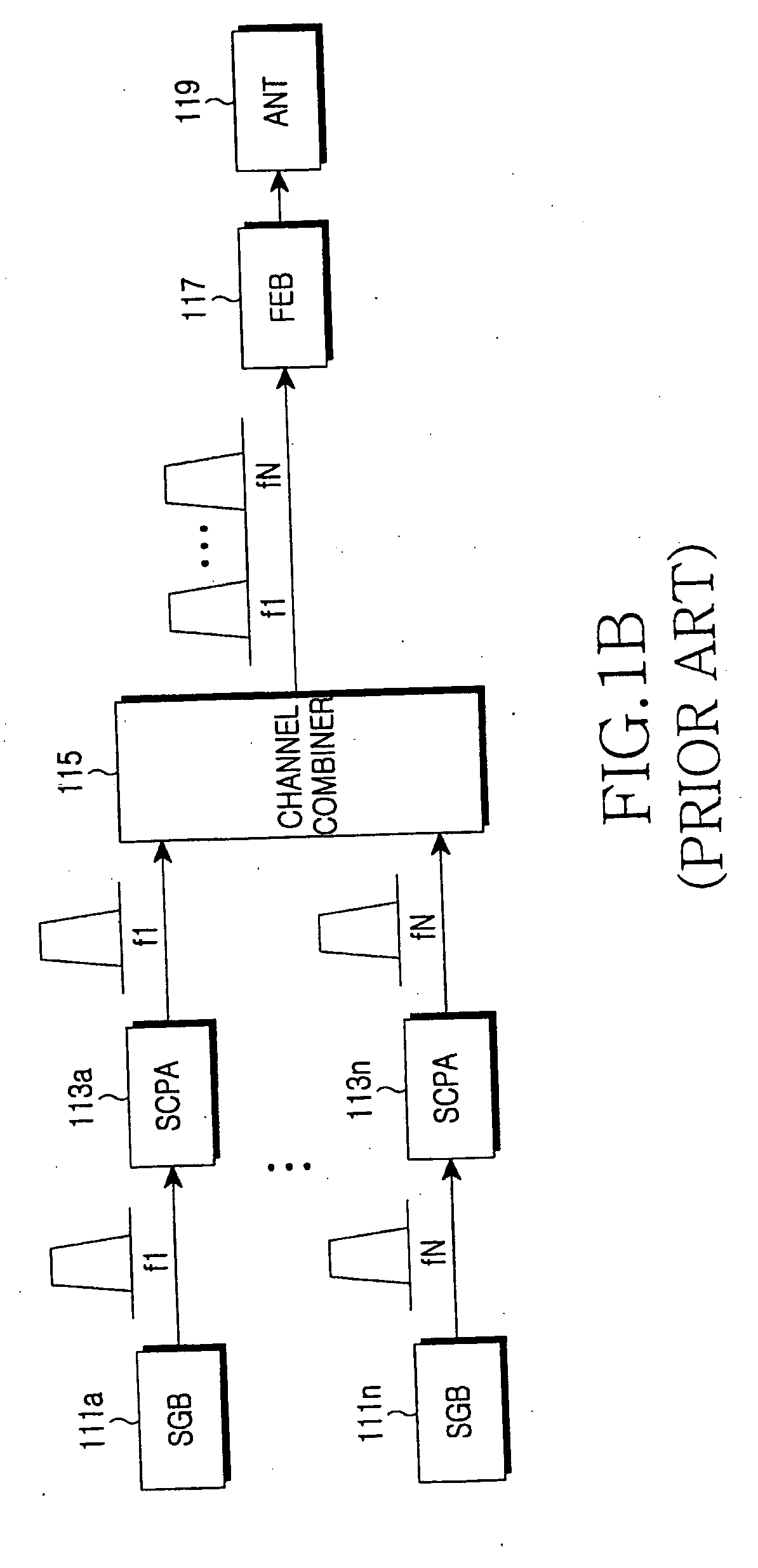

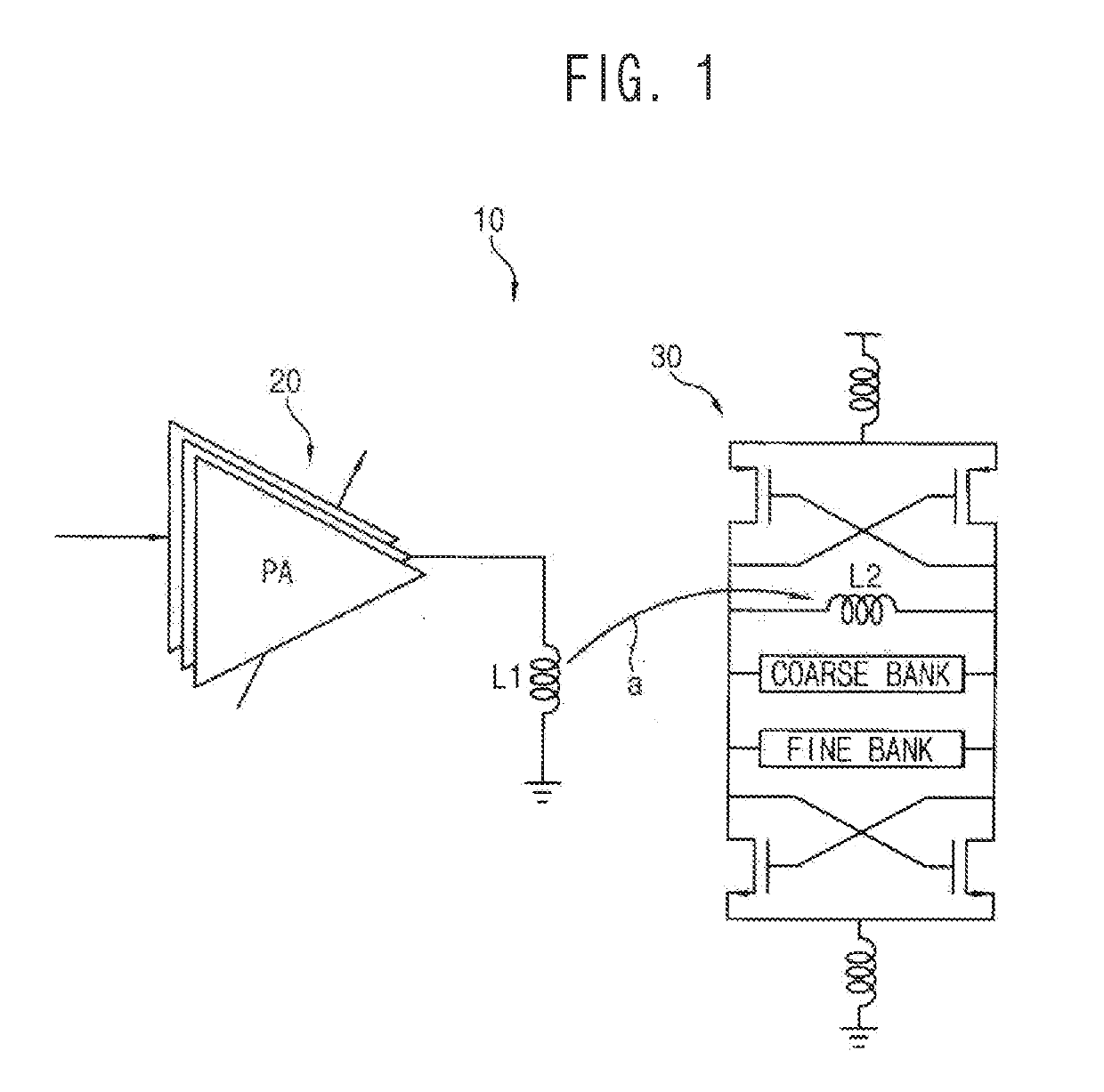

Apparatus and method for transmitting a signal in a communication system

InactiveUS20070178858A1Reduce complexityImprove cost competitivenessResonant long antennasRadio transmissionCommunications systemAudio power amplifier

A method is provided for transmitting a signal in a signal transmission apparatus of a communication system. Upon receiving a signal, the signal transmission apparatus determines a mode of the received signal, in which a power amplifier should amplify the signal; generates a mode control signal corresponding to a single mode, if the mode of the received signal is determined as the single mode; amplifies and transmits the received signal in the single mode according to the mode control signal; generates a mode control signal corresponding to a multi-mode, if the mode of the received signal is the multi-mode; and amplifies and transmits the received signal in the multi-mode according to the mode control signal.

Owner:SAMSUNG ELECTRONICS CO LTD

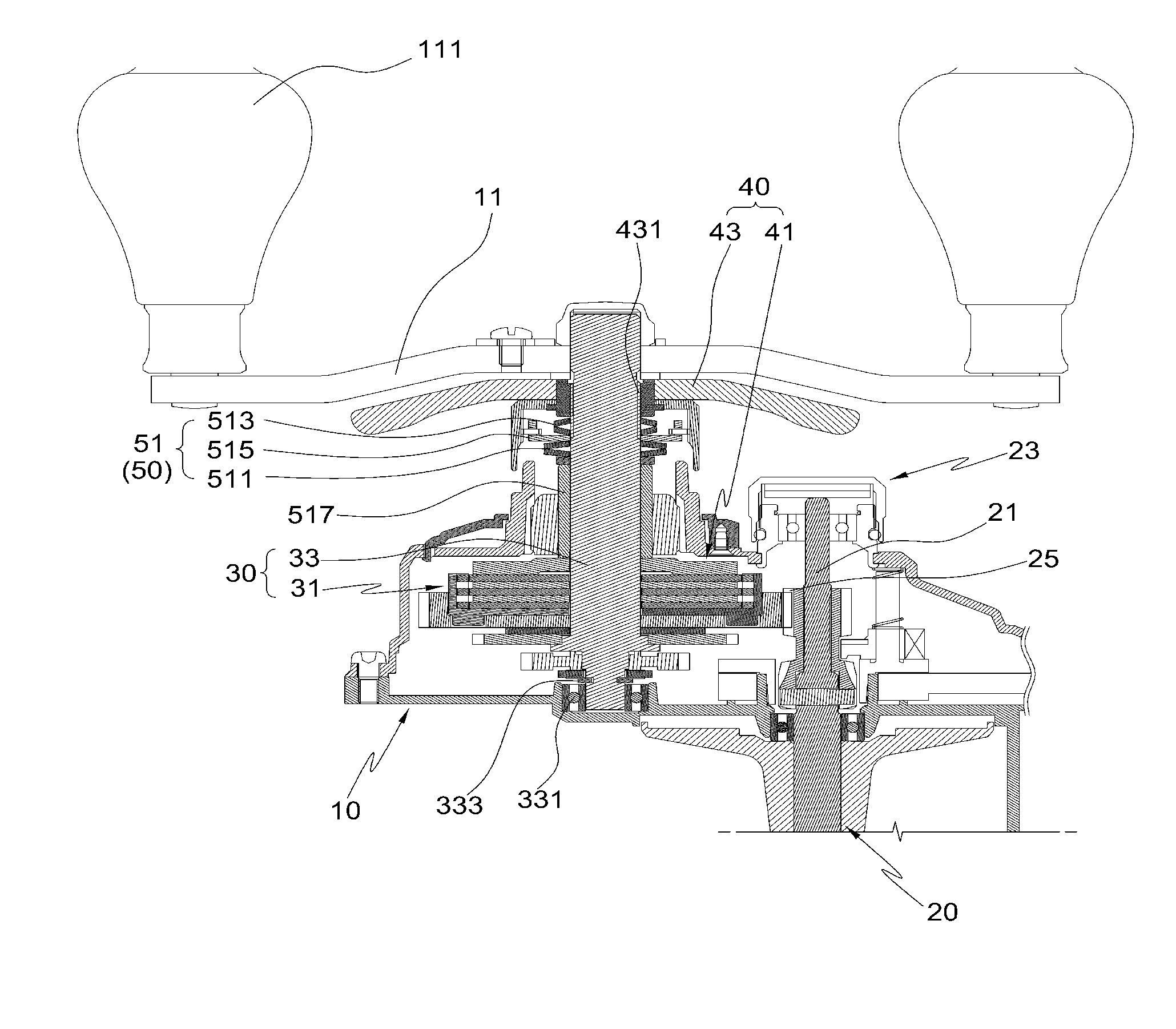

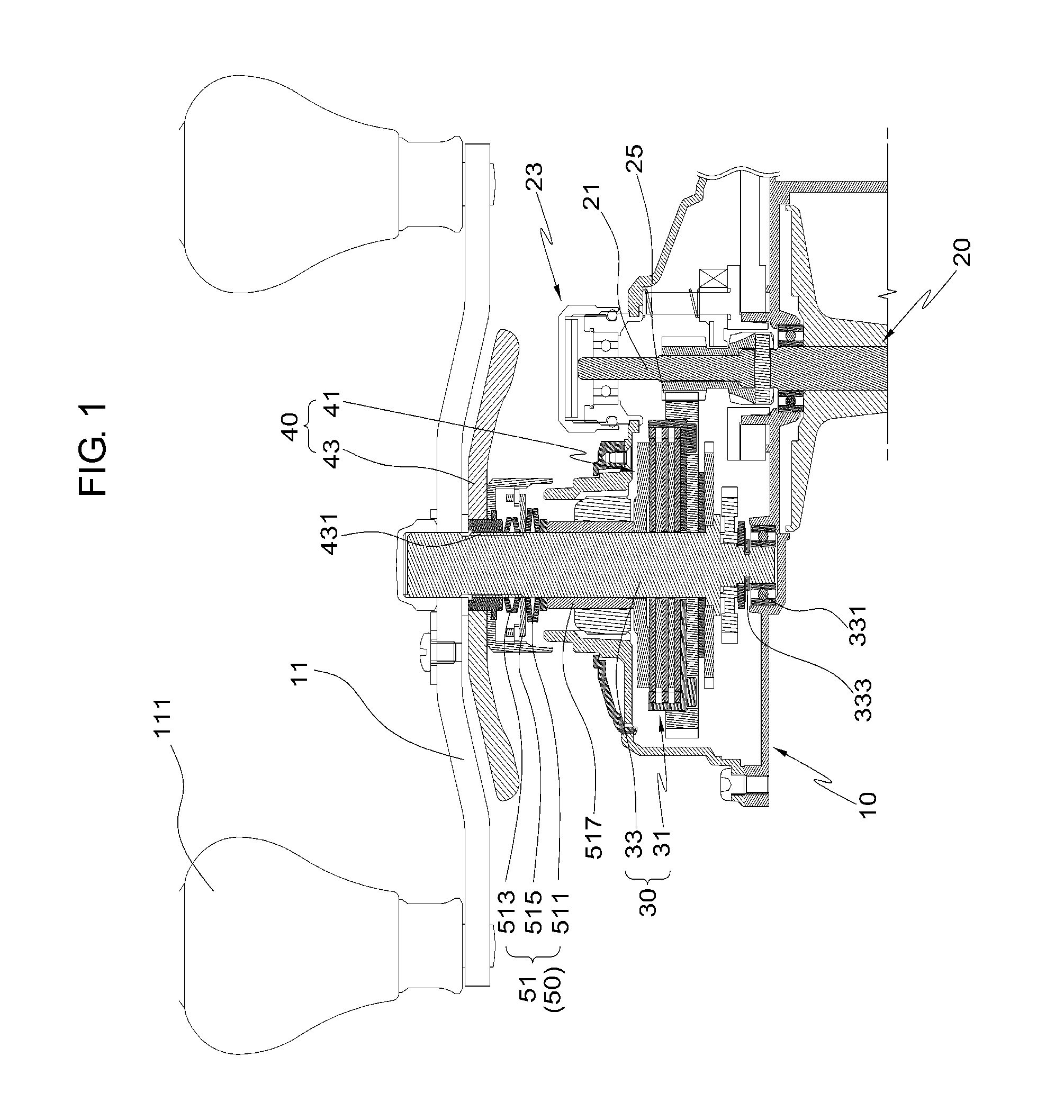

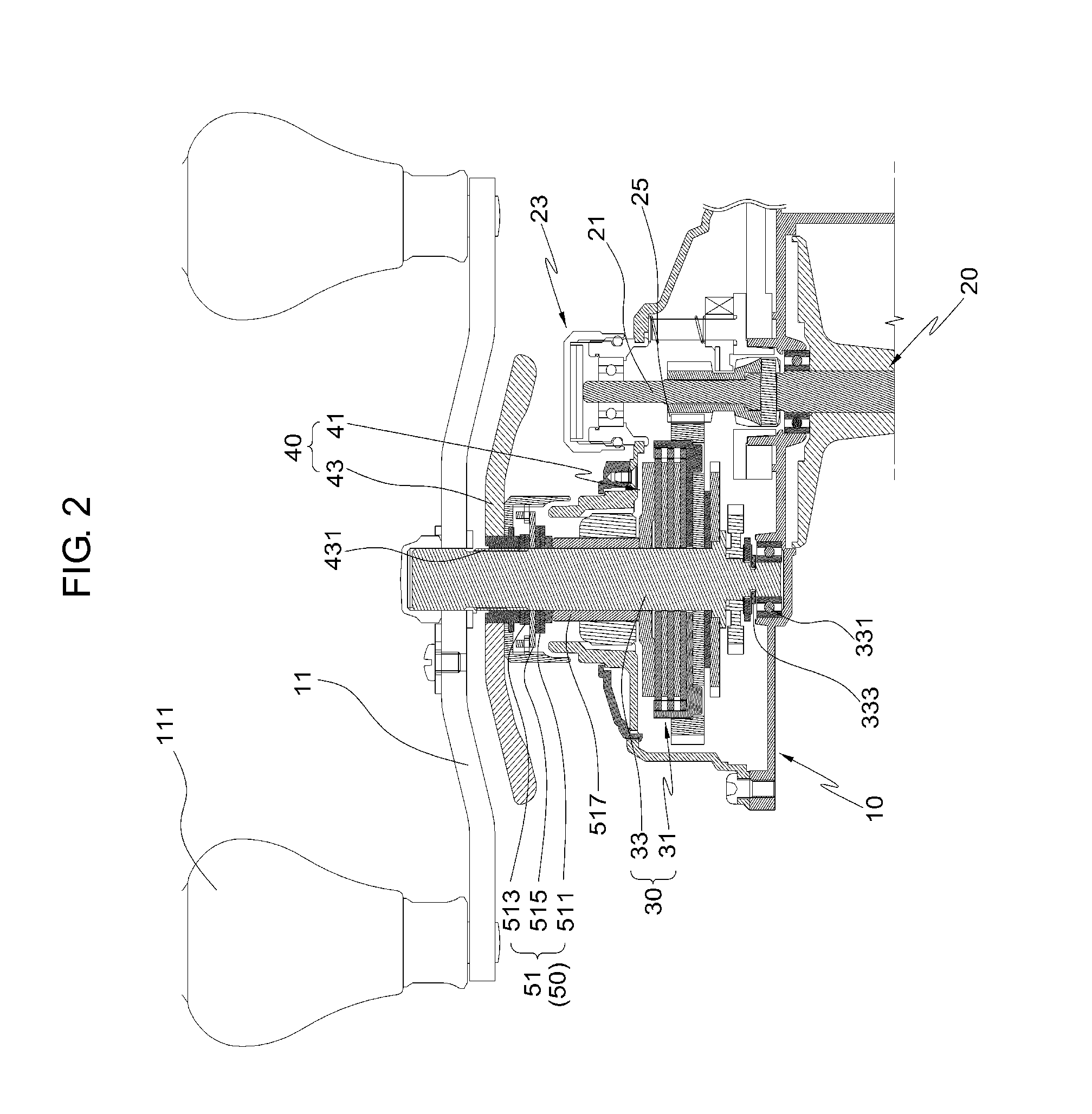

Fishing reel having drag assembly

A fishing reel having a drag assembly. The drag assembly brakes the unwinding rotation of a spool to prevent a fishing line from being excessively rapidly unwound from the spool and thus from being snapped when the fishing line is drawn out by a hooked fish. The drag assembly includes a washer retainer coupled to a drive gear, and a washer group having a brake washer. Therefore, there is no need for the drive gear to have a shape corresponding to the washer group, whereby the manufacturing process can be facilitated, the time it takes to manufacture the fishing reel can be reduced, and the production cost can also be reduced.

Owner:DOYO ENG

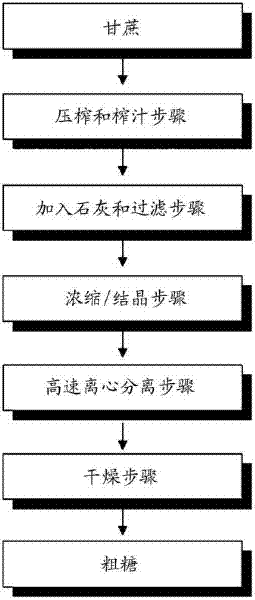

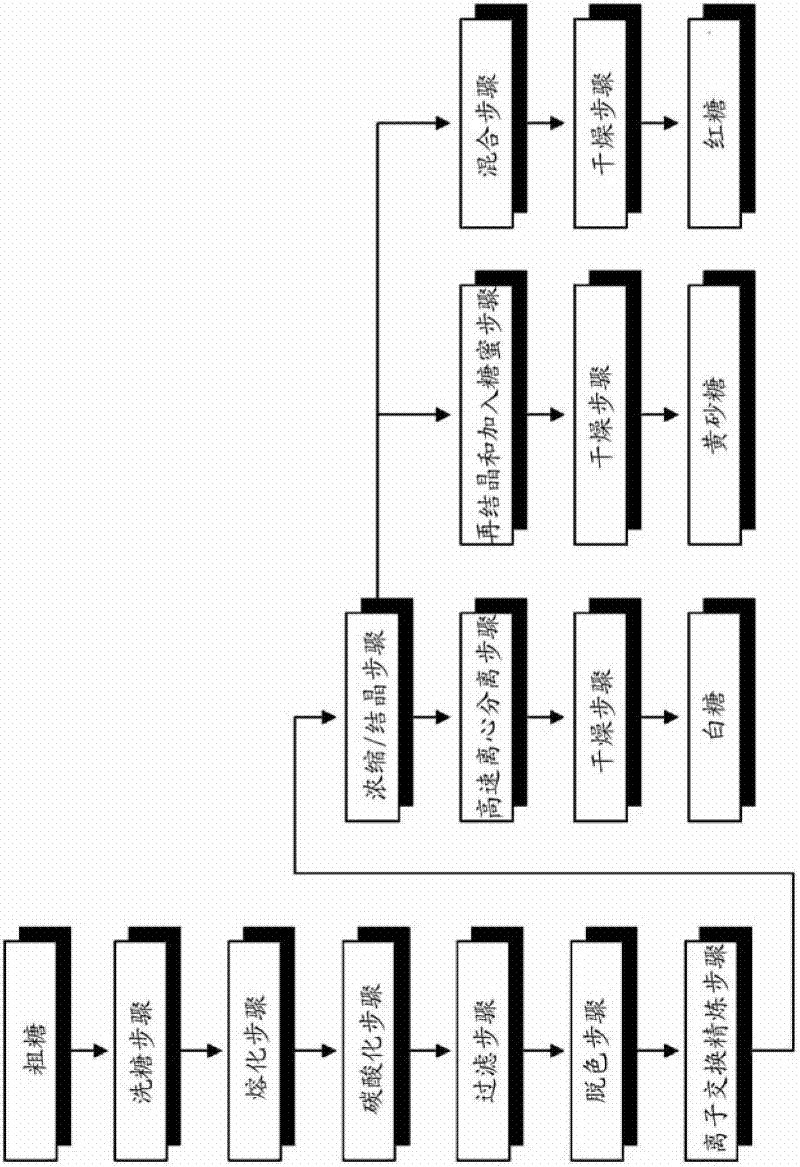

Method for producing white sugar, light brown sugar and dark brown sugar using direct recovery process

ActiveCN102648296AReduce equipment investmentImprove cost competitivenessSugar dryingSugar productsSucroseMother liquor

The present invention relates to a method for producing white sugar, brown white sugar and dark brown sugar, the method including: pressing and juicing sugar cane to extract sugar cane juice; adding lime to the juice and removing foreign matter and impurities from the juice; vacuum-concentrating the filtered juice in a first vacuum concentrator to produce a first crystal slurry containing sucrose; centrifuging the first crystal slurry in a first high-speed centrifuge into a first crystal and a first mother liquor and recovering the first crystal as dark brown sugar or transferring the first crystal to a second vacuum concentrator; vacuum-concentrating the transferred first crystal in the second vacuum concentrator to produce a second crystal slurry containing sucrose; centrifuging the second crystal slurry in a second high-speed centrifuge into a second crystal and a second mother liquor, transferring the second liquor to the pressing and juicing step, and drying the second crystal to produce brown white sugar, or transferring the second crystal to a third vacuum concentrator; vacuum-concentrating the transferred second crystal in the third vacuum concentrator to produce a third crystal slurry containing sucrose; and centrifuging the third crystal slurry in a third high-speed centrifuge into a third crystal and a third mother liquor, transferring the third mother liquor to the first vacuum concentrator, and drying the third crystal to produce white sugar.

Owner:CJ CHEILJEDANG CORP

Stably foamed polyisocyanurate foam material and its preparation method

The invention relates to a combined material for stably foaming a polyisocyanurate foam material, a method for using the combined material to produce the polyisocyanurate foam material, and the polyisocyanurate foam material produced through the method. The combined material for the polyisocyanurate disclosed in the invention is especially suitable for continuous production line technologies. Compared with routine combined materials for the polyisocyanurate, the combined material used in the invention has the advantages of stable material foaming, smooth surface, small foam contraction, high dimensional stability, low defective rate and the like in the polyisocyanurate production process.

Owner:WANHUA CHEM GRP CO LTD +1

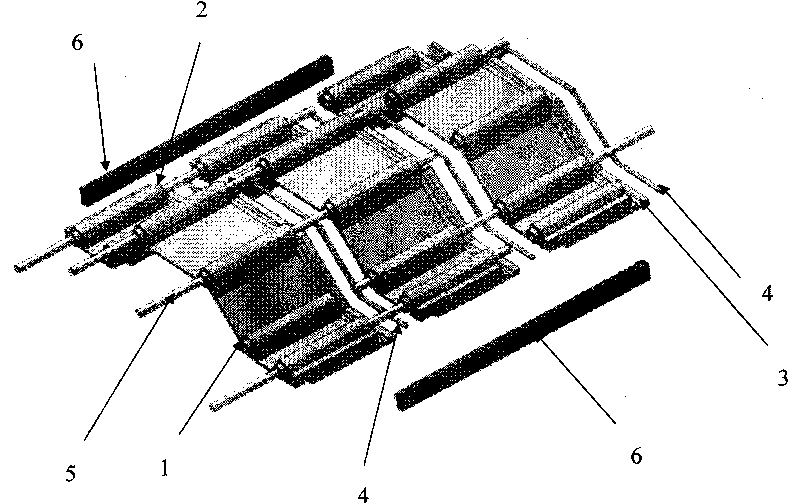

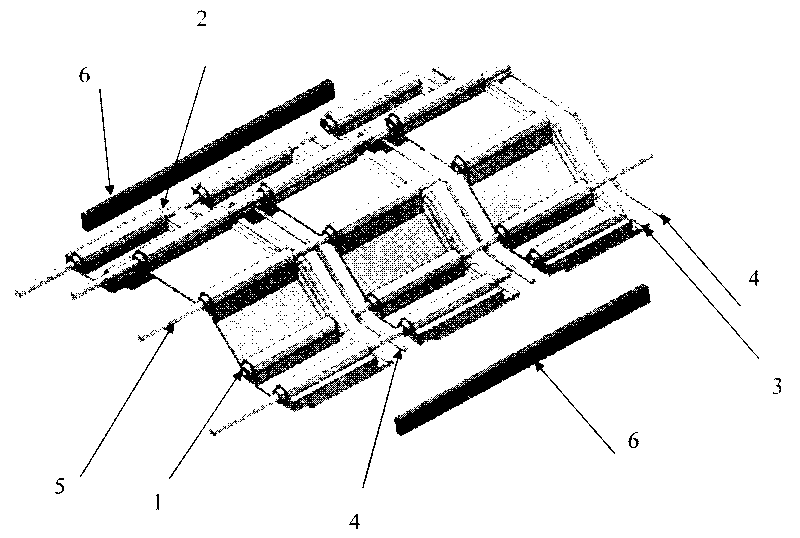

Sintering device and sintering method using induction heating

InactiveCN104271779AReduce the amount of cokeReduce generationFurnace componentsFurnace typesMetallurgyConductive materials

Disclosed are a sintering device and a sintering method using induction heating, wherein a raw ore can be heated by inducing the heating of a highly conductive material included in the raw ore through magnetic inductance of an induction coil. The sintering device using induction heating of the present invention manufactures a sintered ore by inductively heating a raw ore, comprising: an induction case; and a heat inducing body which is mounted in the induction case and induces, through magnetic induction, the heating of the raw ore that is accommodated within the induction case or penetrates the induction case.

Owner:POSCO

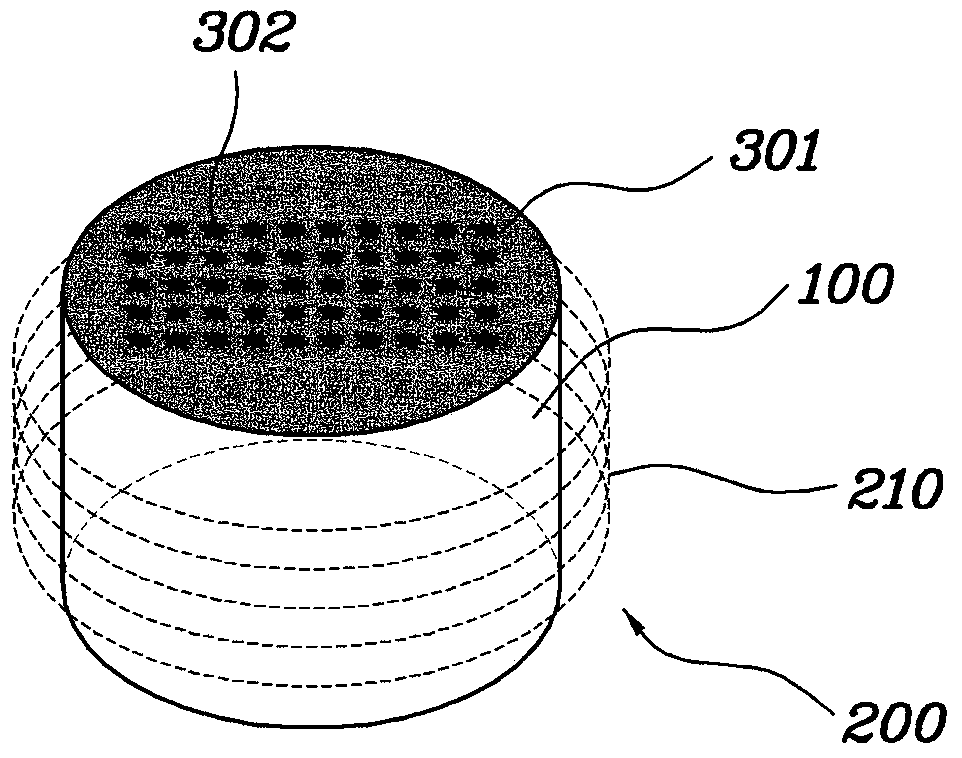

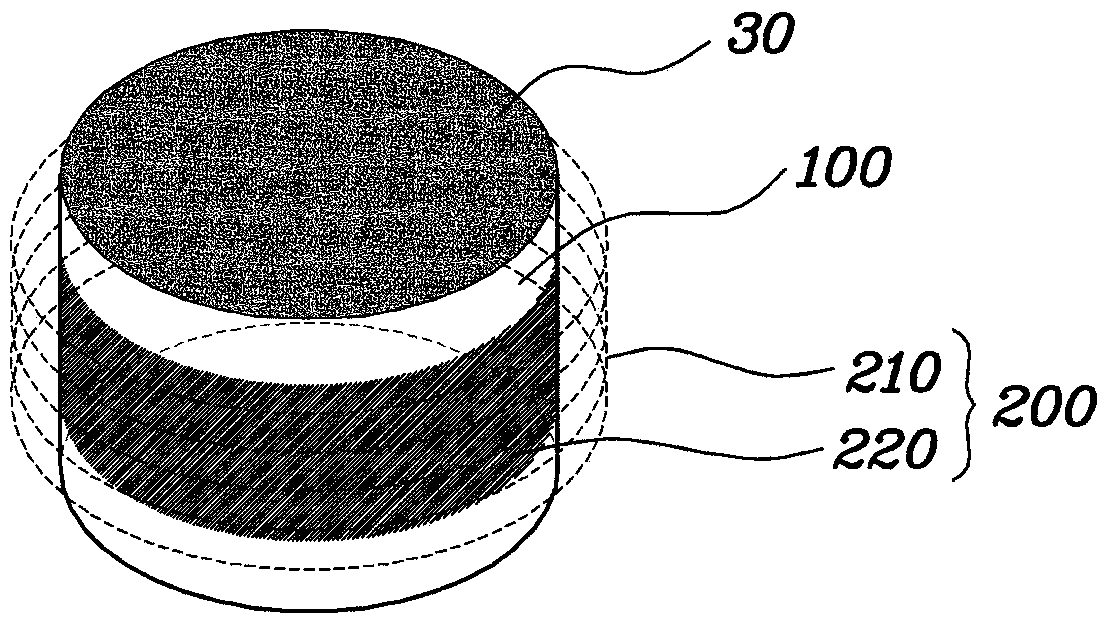

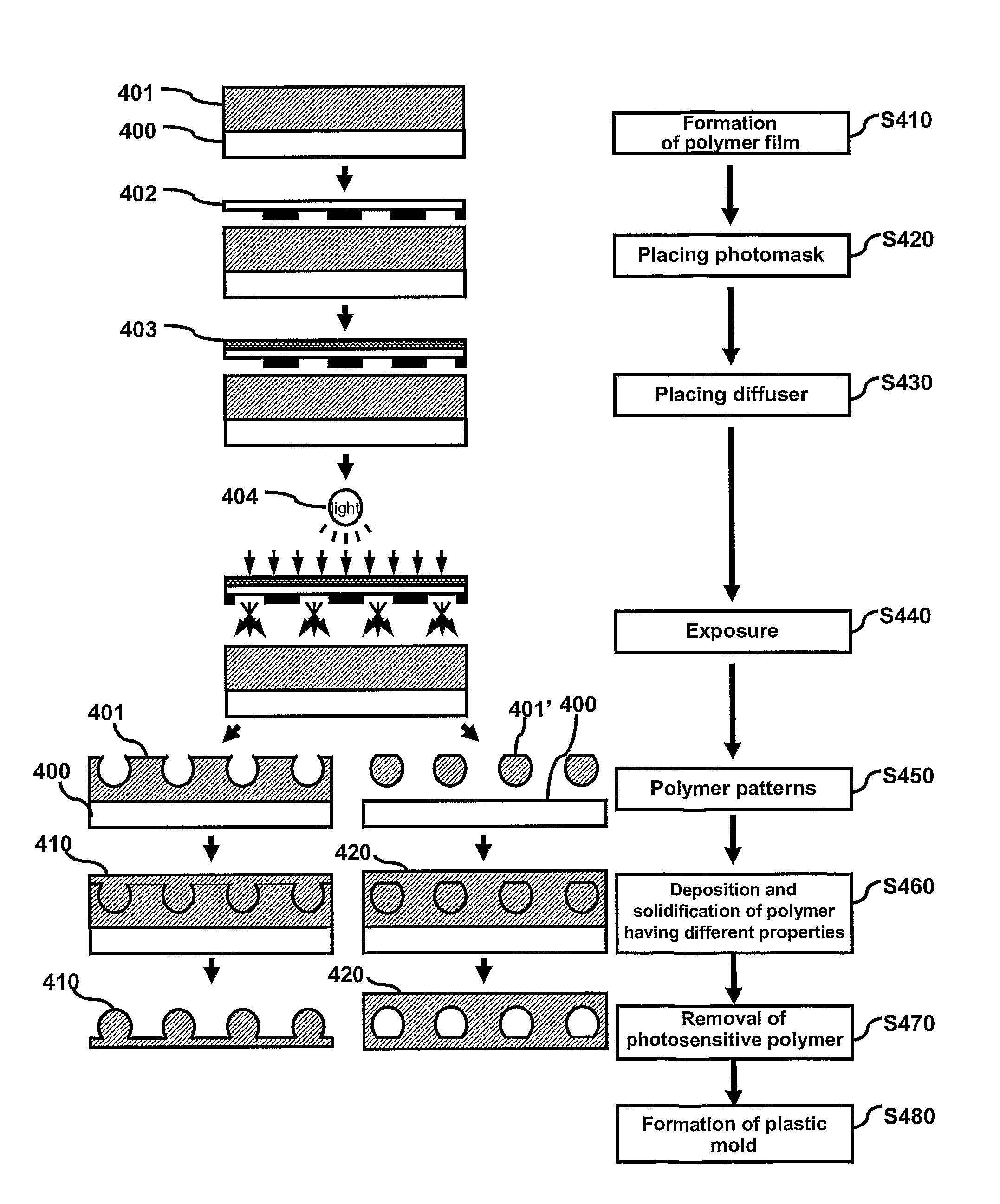

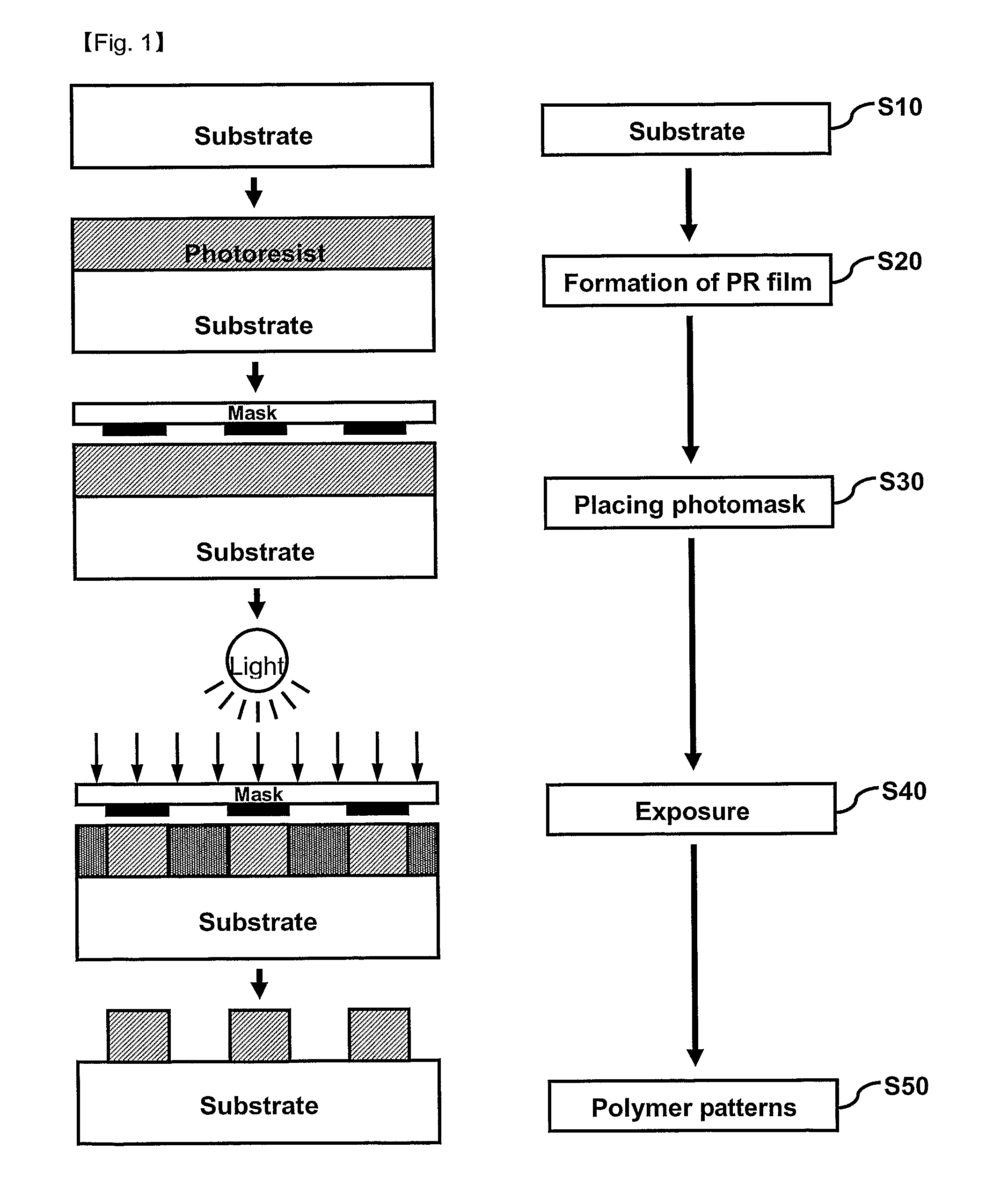

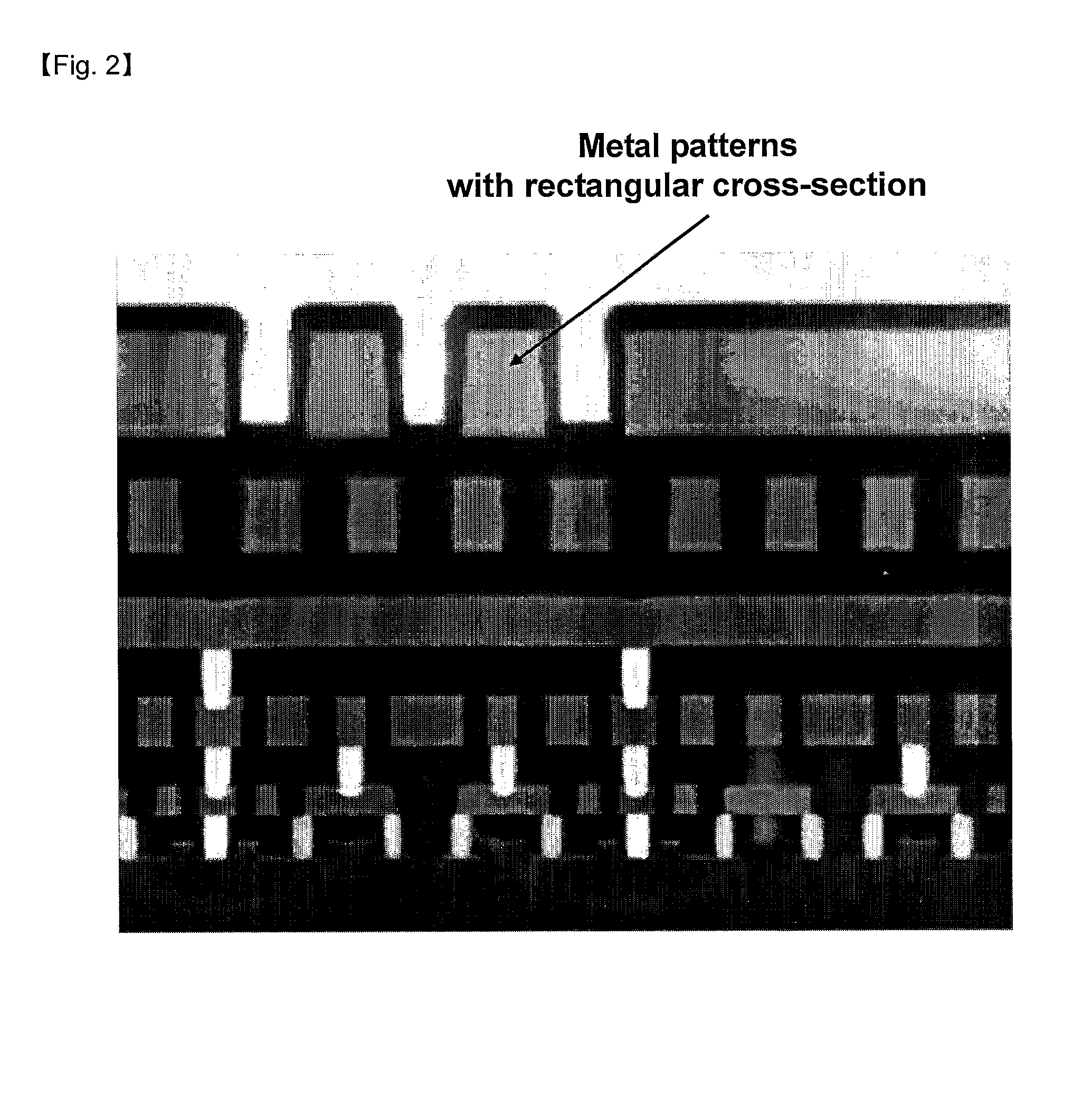

Polymer pattern and metal film pattern, metal pattern, plastic mold using thereof, and method of the forming the same

InactiveUS20100046079A1Simple processEliminate needSemiconductor/solid-state device detailsSolid-state devicesLithography processPhotosensitive polymer

The present invention relates to polymer patterns of various shapes formed using modifications of means and methods used in the prior lithography process, and the metal film patterns, metal patterns and plastic molds using the polymer patterns, as well as methods of forming these patterns and molds. The method of forming the polymer patterns comprises the steps of: (a) depositing a photosensitive polymer on the substrate to form a polymer film; (b) placing a photomask on the polymer film; and (c) irradiating the polymer film with a light moving in random direction through the photomask, so as to form at least one pattern which is concave from the surface of the polymer film in a direction perpendicular to the substrate and extends in a direction parallel to the substrate. The inventive polymer patterns have at least one pattern which is concave from the surface of the polymer film in a direction perpendicular to the substrate and extends in a direction parallel to the substrate. The vertical cross-section of the concave patterns has at least one curved surface.

Owner:KOREA ADVANCED INST OF SCI & TECH

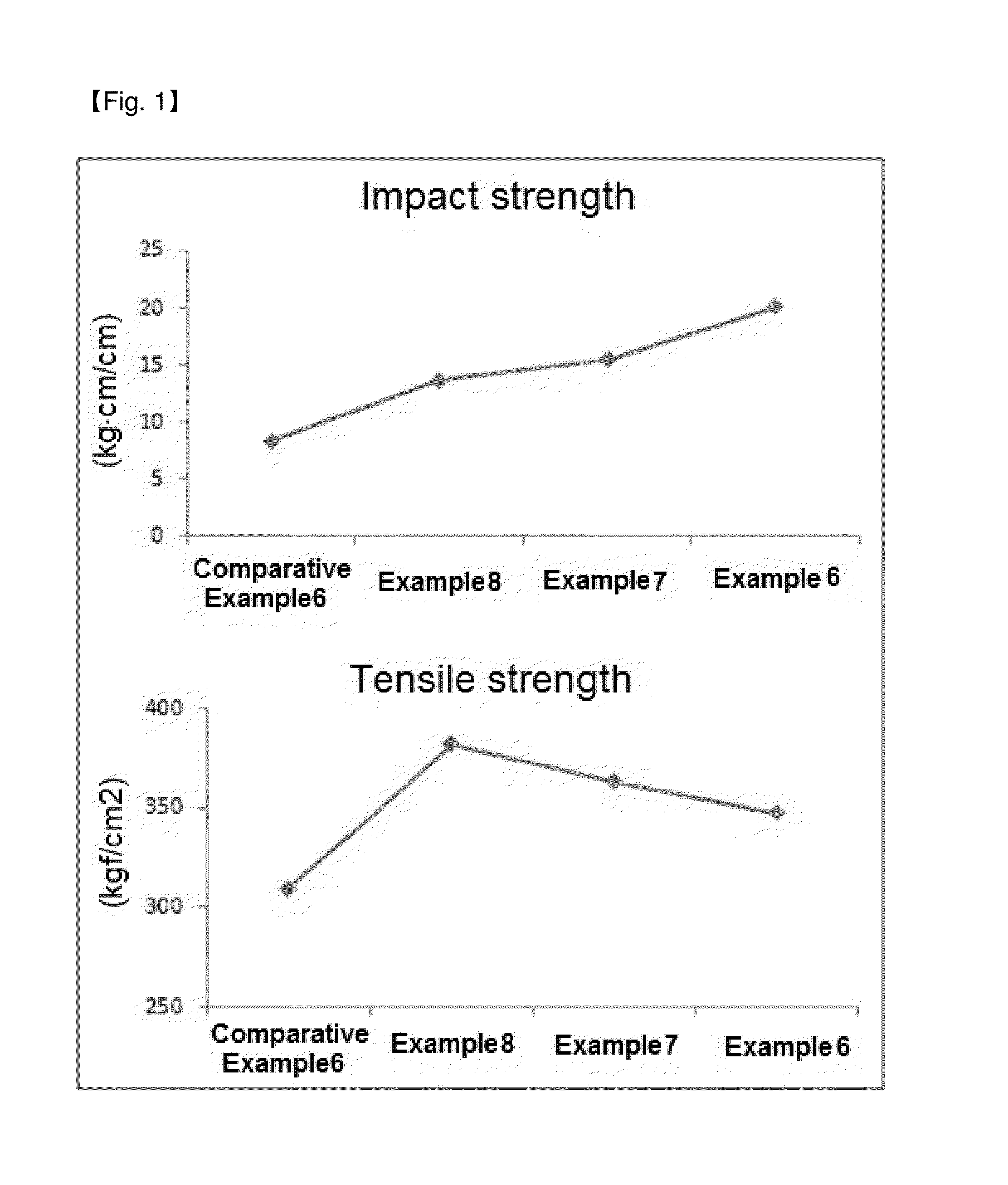

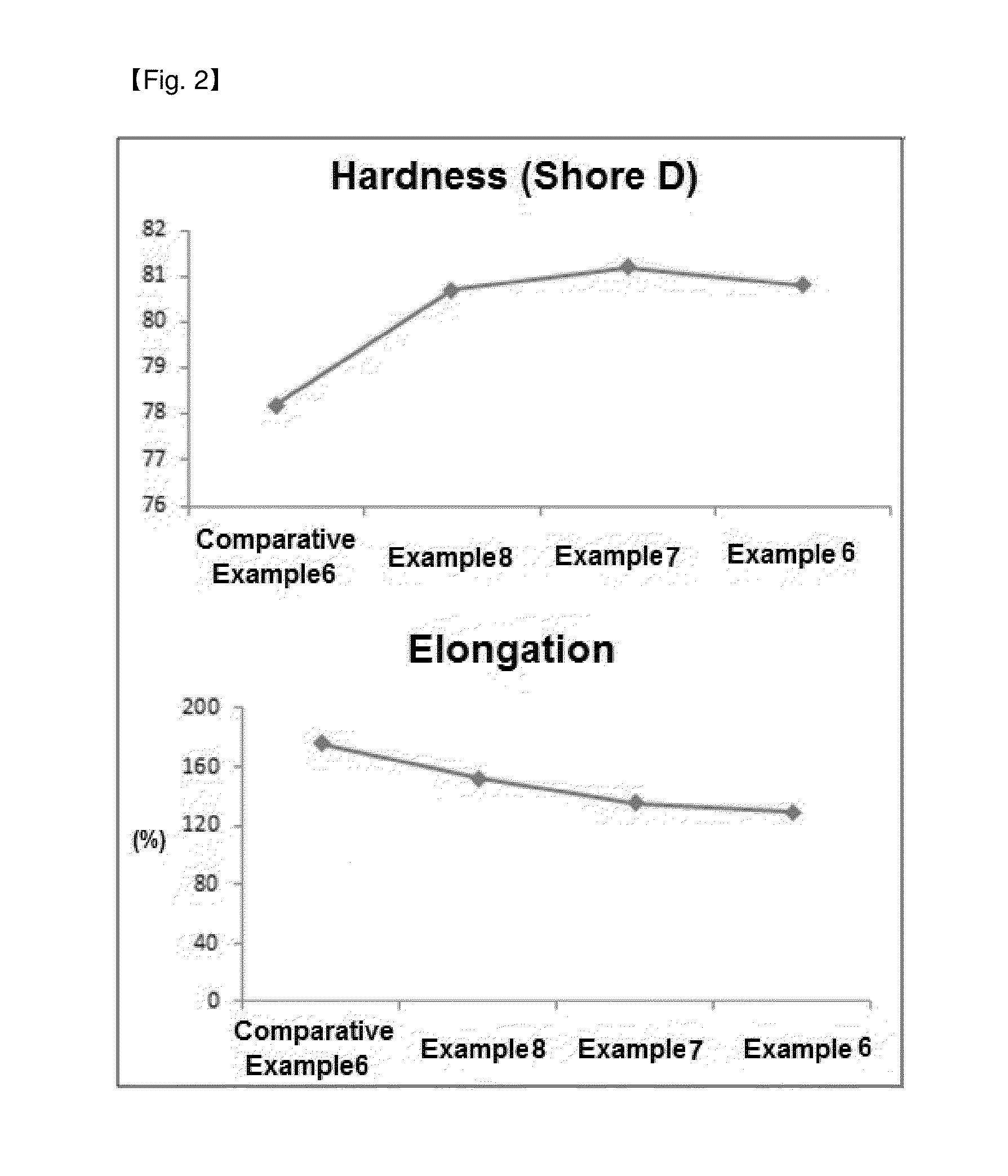

PVC-based compound composition

The present invention relates to a polyvinyl chloride (PVC)-based compound composition, and more specifically, to a PVC-based compound composition that uses a PVC-based copolymer having internal plasticity prepared by suspension polymerization together with a PVC resin, thereby increasing compatibility with the PVC resin to shorten the gelling time, lowering the load at the time of extrusion to increase production in the same process conditions, and partially showing an impact modifier substitution effect.

Owner:HANWHA CHEMICAL CORPORATION

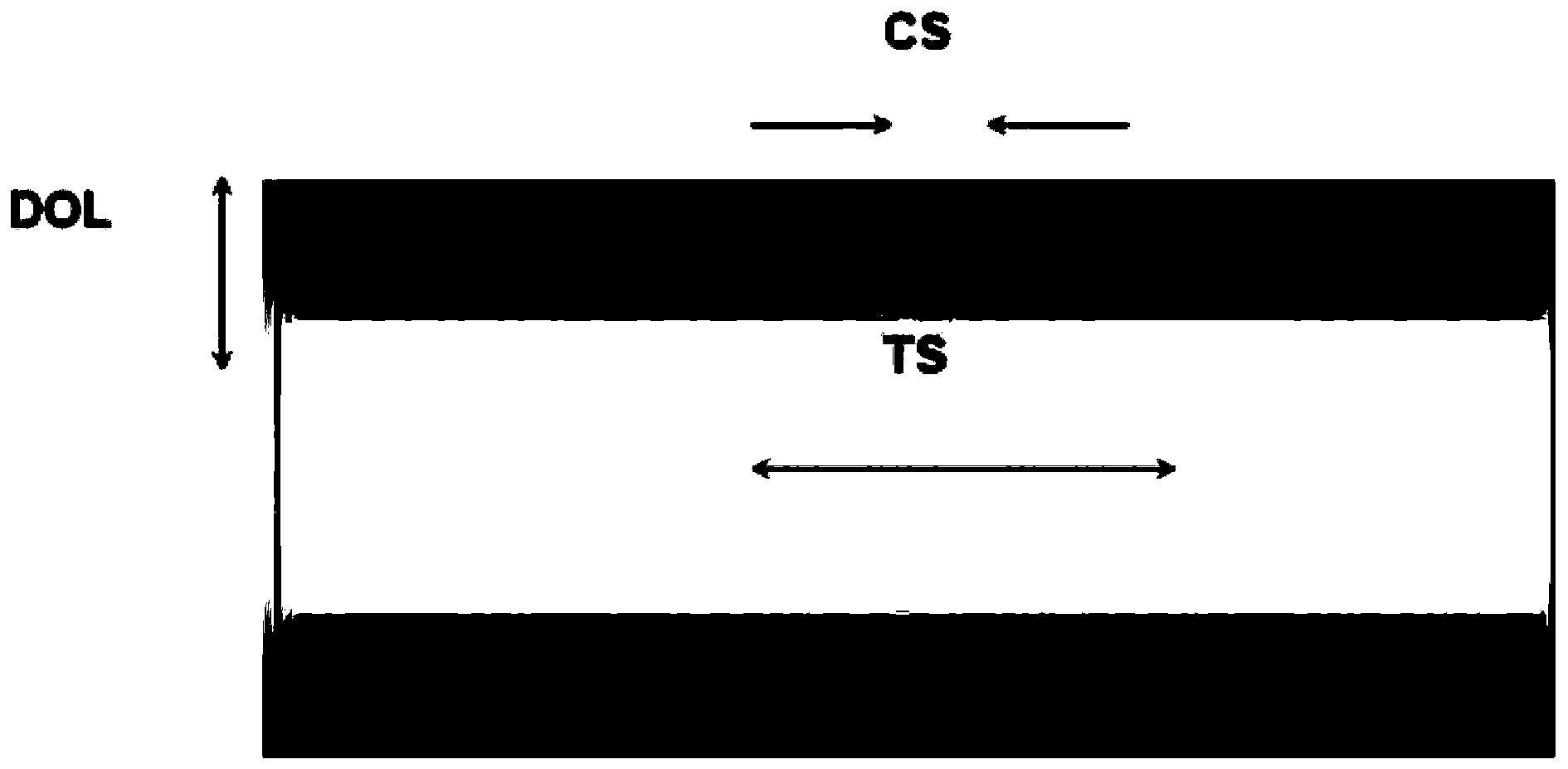

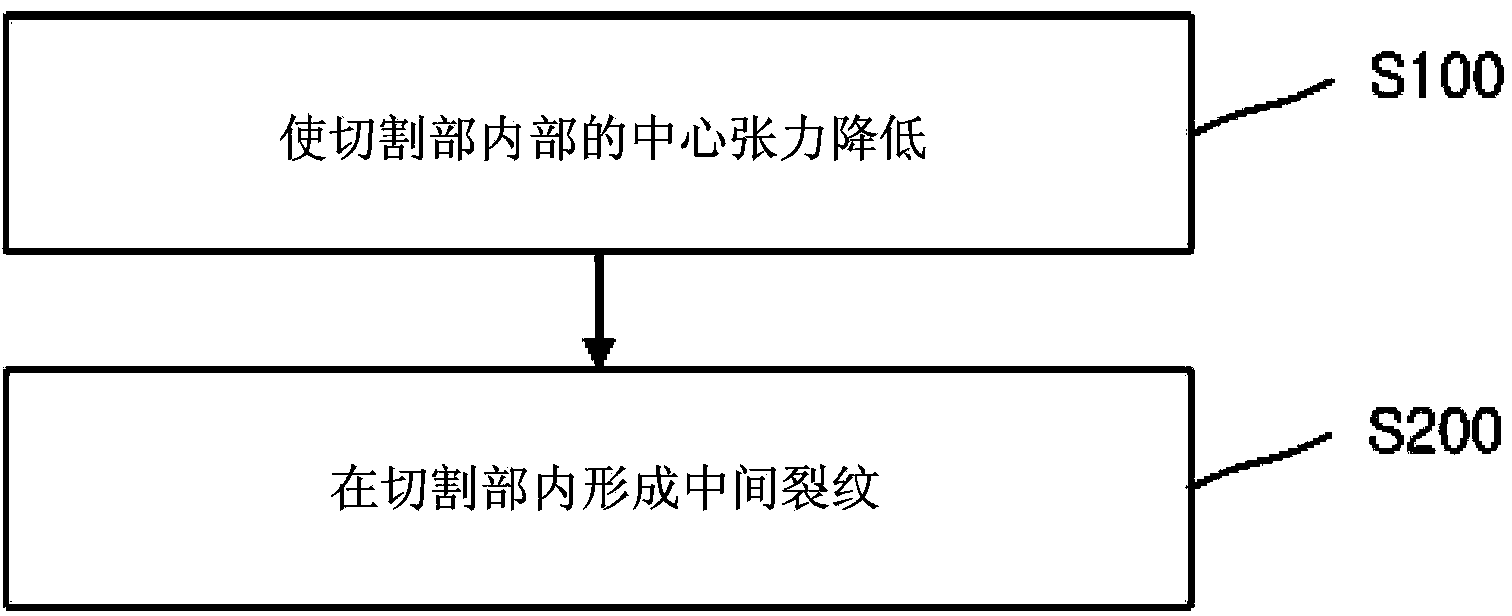

Cutting method and stage for cutting of tempered glass

InactiveCN103570232AImprove cost competitivenessConveyorsMetal-working apparatusToughened glassGlass sheet

A cutting method and cutting stage of toughened glass with which a piece of toughened glass is divided into unit pieces of toughened glass. The cutting method cuts a piece of toughened glass which is strengthened by forming a compressive stress in the surface of a raw glass plate. The method includes the steps of reducing the central tension inside a cutting portion of the piece of toughened glass that is to be cut by concavely bending the cutting portion; and cutting the piece of toughened glass by forming a median crack in the cutting portion.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

Large-diameter wear-resistant steel ball and production process thereof

ActiveCN103320695ALow costImprove cost competitivenessFurnace typesGrain treatmentsSteelmakingProduction line

The invention discloses a large-diameter wear-resistant steel ball. The large-diameter wear-resistant steel ball comprises the following materials in percentage by weight: 0.6-07% of C, 0.95-1.25% of Mo, 0.01-0.02% of Ti, 0.25-0.45% of Si, not more than 0.03% of S, not more than 0.035% of P, not more than 0.2% of Cu, and the balance of Fe. The production of the large-diameter wear-resistant steel ball has the beneficial effects as follows: 1, according to the most advanced international qualification of large-diameter (120-200mm) forged balls, a material superior to domestic high-carbon alloy steel is developed by combining advantages of an existing domestic steelmaking technology and a precious metal mineral resource condition, and the cost can be lower than one fifth, so that the product cost competitiveness is increased after utilization; and 2, a novel, efficient and large-diameter wear-resistant forged steel ball with the leadership in domestic and overseas markets can be produced by combining an existing roll forging steel ball automatic production line with the technology provided by the invention, so that the domestic blank is filled up, and meets the requirements on installation and use of domestic and overseas large-scale ball mills.

Owner:SHANDONG HUAMIN STEEL BALL

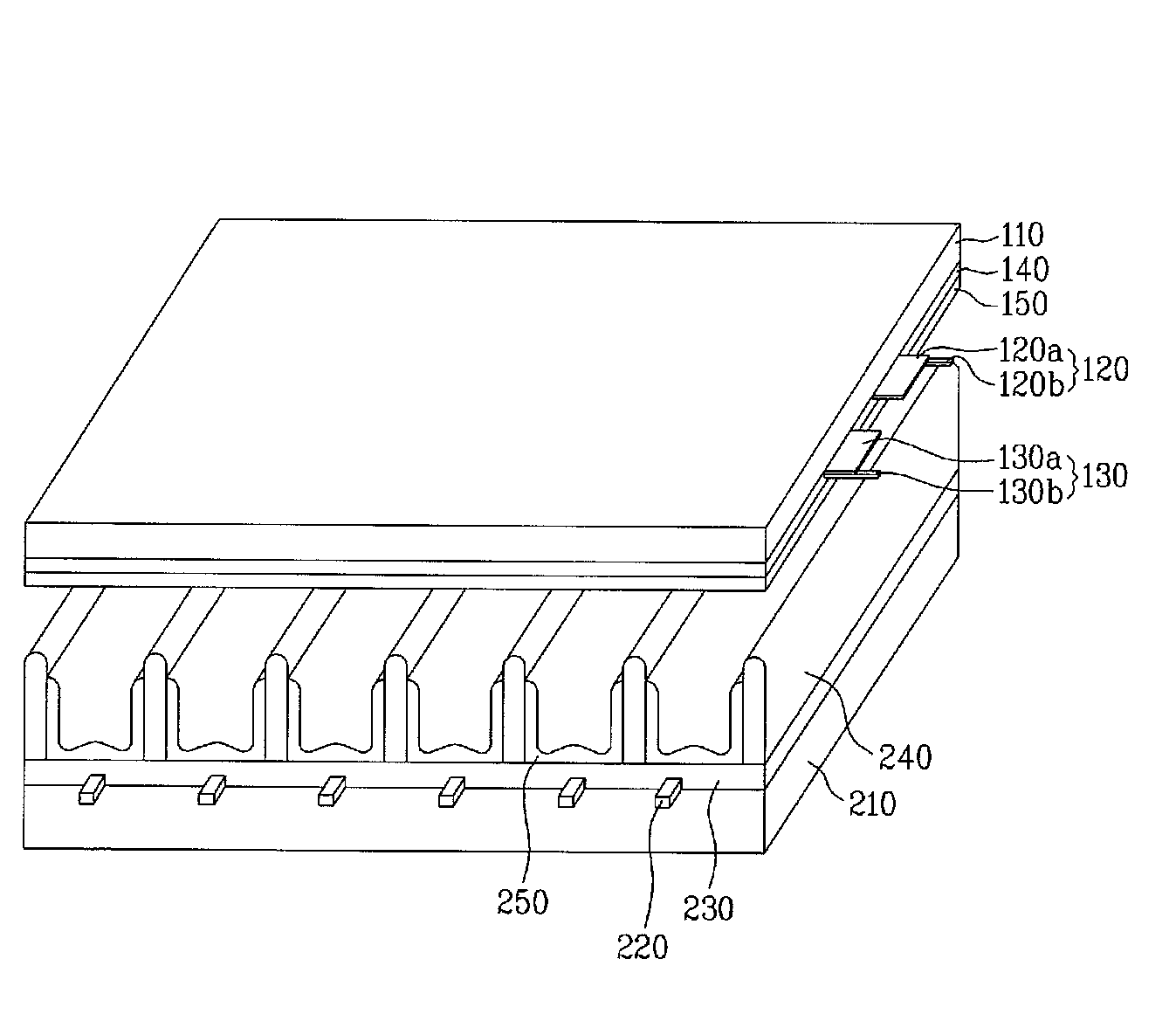

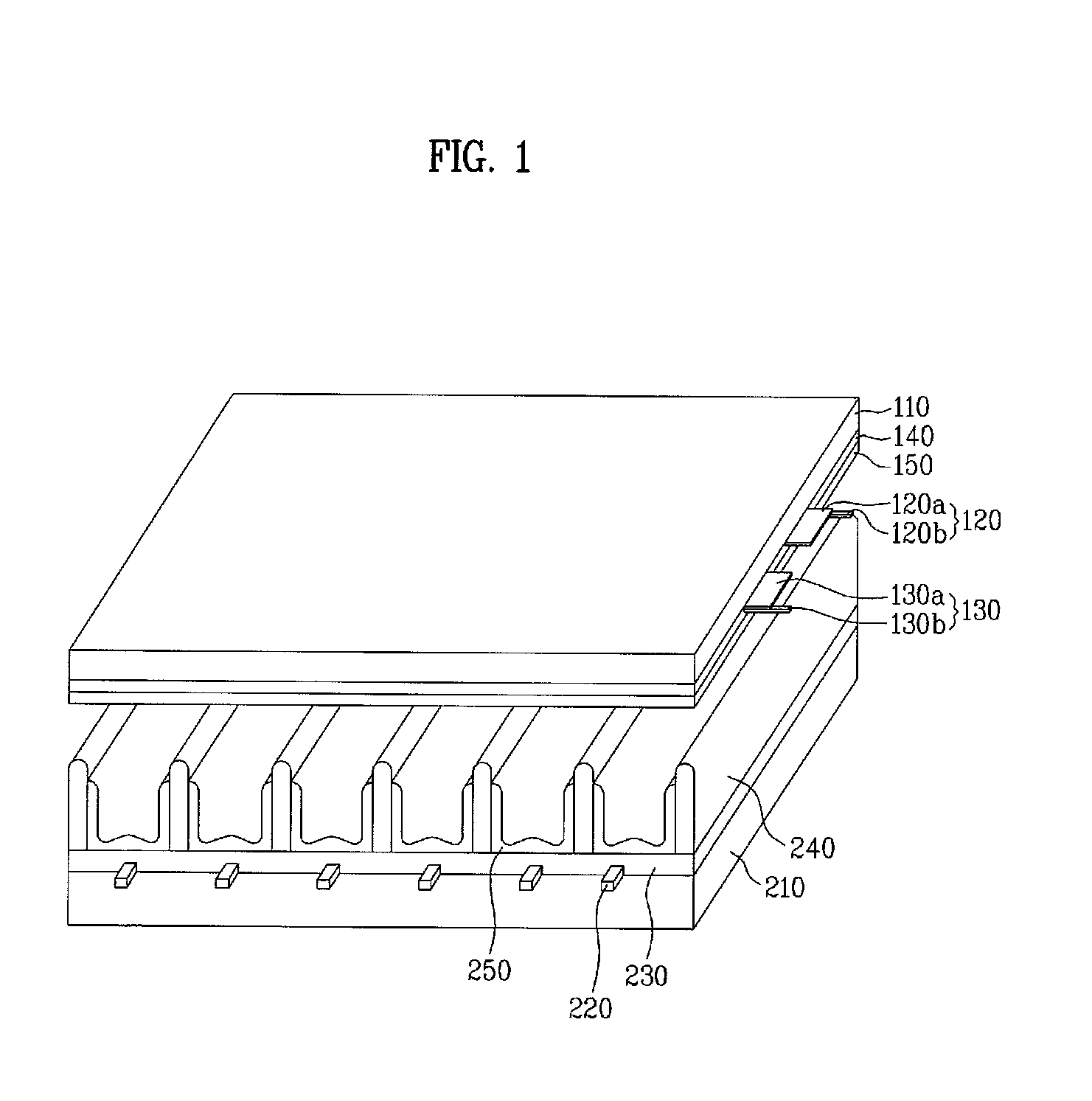

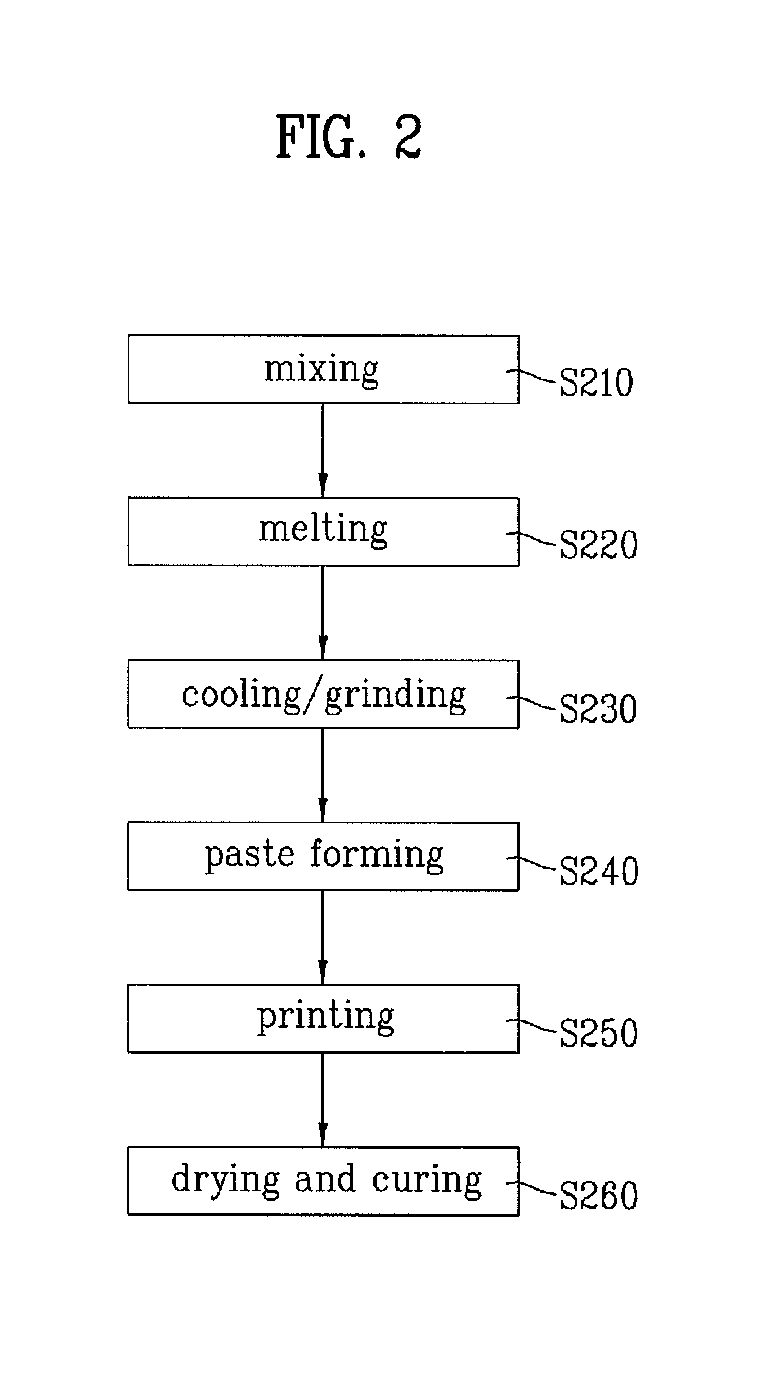

Plasma display panel, a method for manufacturing a plasma display panel, and related technologies

InactiveUS20080085423A1Improve cost competitivenessLower unit costAlternating current plasma display panelsNatural mineral layered productsOptoelectronicsDielectric layer

A plasma display panel includes a substrate with electrodes. A dielectric layer is disposed over the substrate and covers the electrodes. The dielectric layer includes 10 to 60 mol % of Bi2O3, 5 to 40% of CuO, and 15 to 40 mol % of B2O3.

Owner:LG ELECTRONICS INC

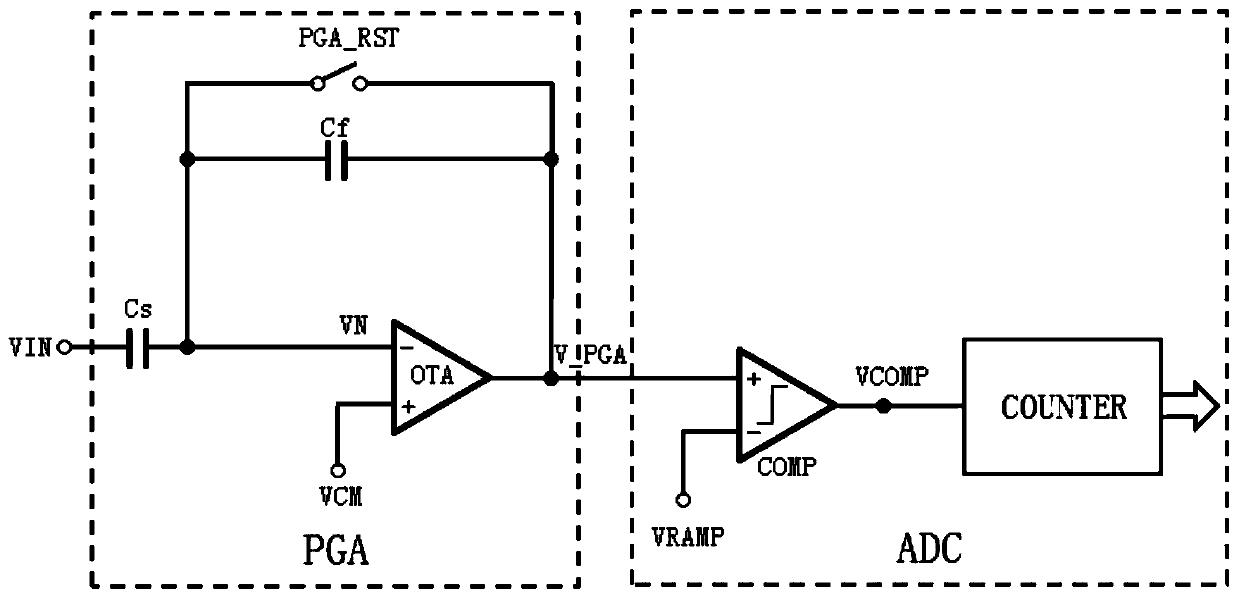

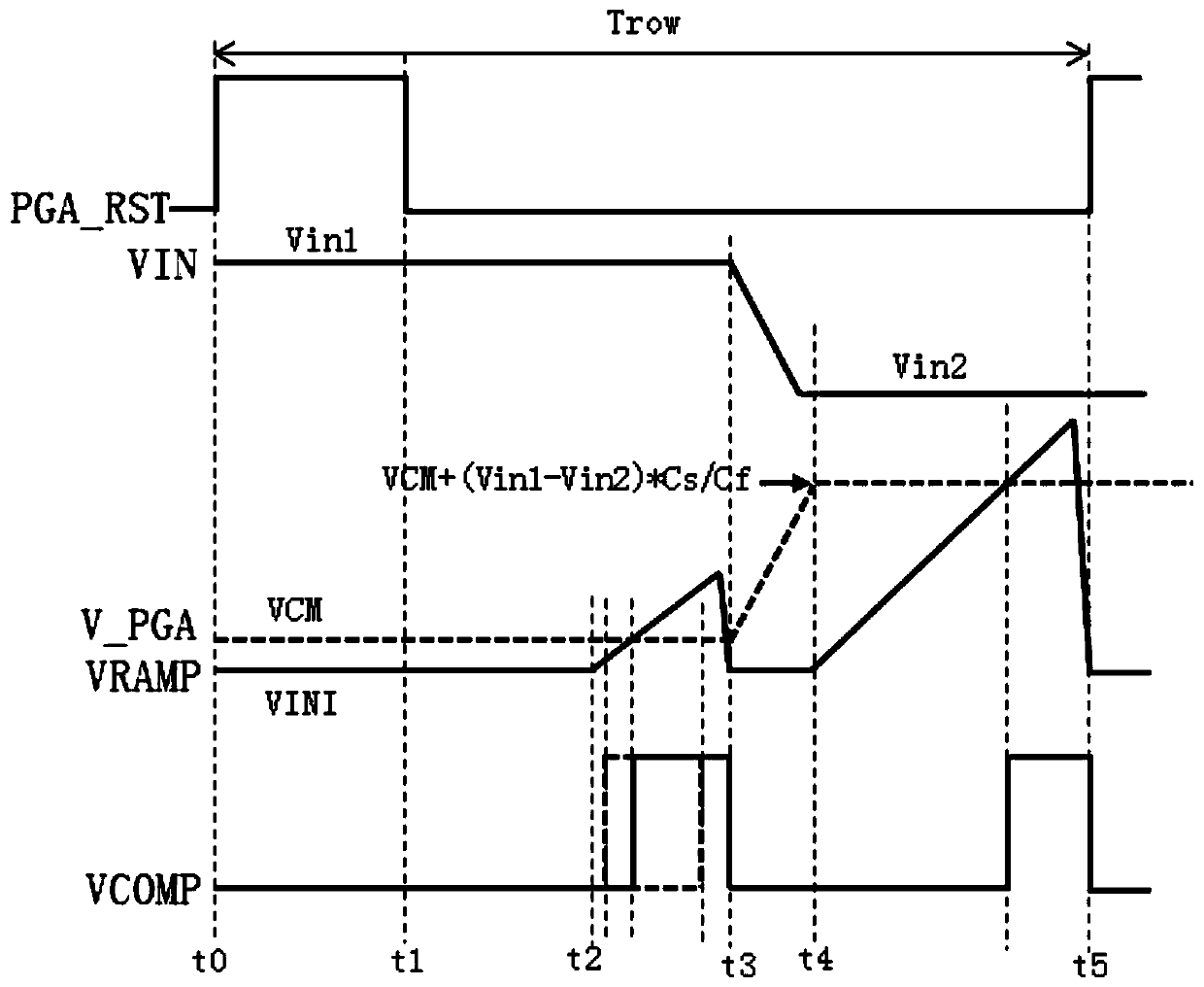

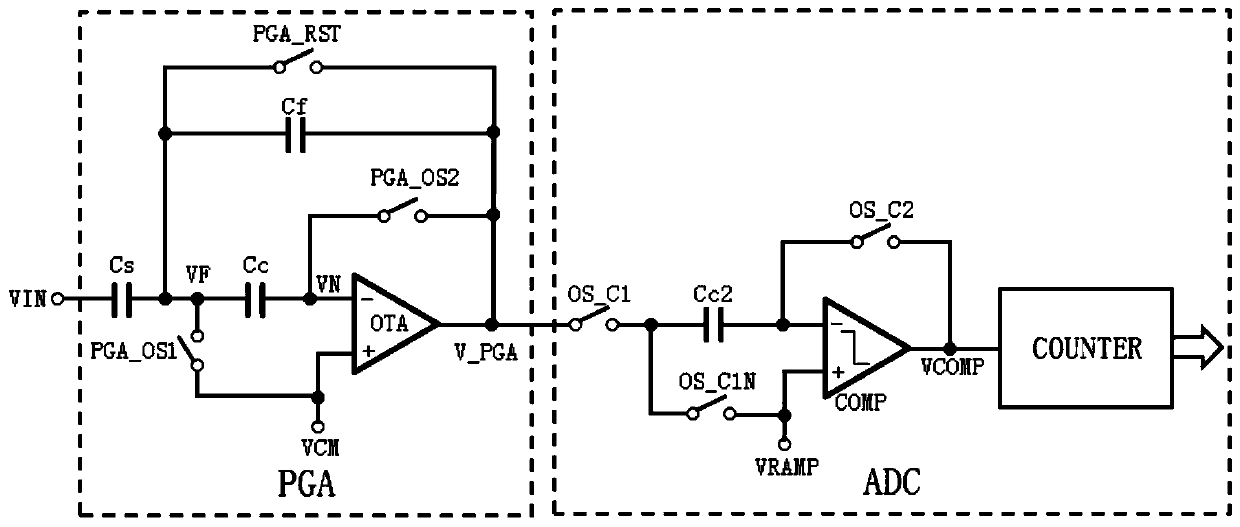

Readout circuit structure and working time sequence control method thereof

ActiveCN111327848AWith offset cancellation functionSave extra spaceTelevision system detailsColor television detailsCapacitanceSequence control

The invention provides a readout circuit structure and a working time sequence control method thereof. The readout circuit structure comprises a programmable gain amplifier circuit and an analog-to-digital converter circuit which are arranged in a coupling mode, the programmable gain amplifier circuit comprises a sampling capacitor, a feedback capacitor, an operational amplifier and a reset control switch, and the analog-to-digital converter circuit comprises a comparator and a counter. Wherein one end of the reset control switch is connected with one input end of the operational amplifier, the other end of the reset control switch is connected with the output end of the comparator, the output end of the operational amplifier is connected with one input end of the comparator, and the otherinput end of the comparator is connected with a reference voltage. According to the technical scheme, the readout circuit structure has an offset elimination function, and meanwhile, the use of capacitors and switches can be reduced, so that the area and the power consumption are saved, the time sequence complexity of control signals is reduced, and the overall circuit precision is improved.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT +1

Modular LED street lamp

InactiveCN101737736ALow costImprove cost competitivenessPoint-like light sourceOutdoor lightingEngineeringMechanical engineering

The invention relates to a modular LED street lamp. Each single module comprises screw rods, a convex ring, a concave ring, semicircular concave grooves, elastic rubber rods and fastening pressing strips. Modules are connected in an overlapping way. The connection surface of the adjacent two modules is divided into a part at the top and a part at the bottom, wherein one of the two parts is concave, and the other part is convex. The left surface and the right surface are concave and convex oppositely. The body of the modular LED street lamp, which is perpendicular to the contact and connection surface of adjacent two modules, is externally and longitudinally provided with a locking hole which penetrates through the whole modules, and the locking holes are penetrated by the rods and are fastened by nuts one two ends. The connection surface of adjacent two locking holes is provided with the convex ring and concave ring which are used for guiding and limiting. The left contact and connection surface and the right contact and connection surface of the adjacent two modules on the upper part are respectively provided with one semicircular concave groove, and the two semicircular concave grooves are opposite to each other and can be combined together to form a full circle. One elastic rubber rod whose diameter is larger than the diameter of each of the semicircular concave grooves is filled in each semicircular concave groove. Two sides of the horizontal line connecting the multiple modules are respectively provided with one fastening pressing strip for limiting.

Owner:天津市易伸技术有限公司

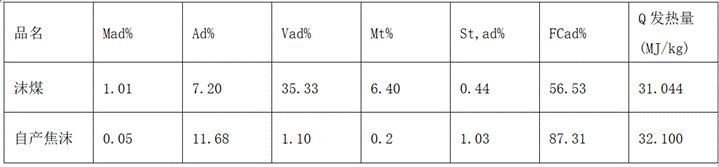

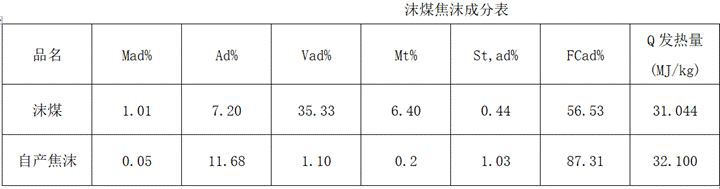

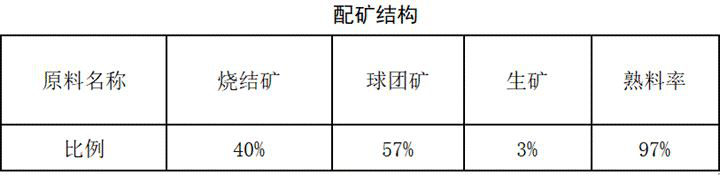

Method for reducing process energy consumption of European smelting furnace

PendingCN114395655AImprove cost competitivenessHigh compressive strengthShaft furnaceCokeComponents of crude oil

The invention discloses a method for reducing process energy consumption of an European smelting furnace, which is characterized in that acid pellets are matched with high-alkalinity sinter, and according to the cost performance and economical efficiency of ore smelting, an ore matching structure suitable for a furnace charge structure of a reduction furnace of the European smelting furnace is obtained as follows: 40% of sinter, 57% of pellets, 3% of raw ore and 97% of clinker rate. Components of the sintered ore are stabilized, the alkalinity of the sintered ore is stabilized to be R = 2.4 times, the content of MgO is 2.4%, and the content of rotary strands is larger than 80%; coal injection is conducted on a vault, the coal injection amount stably reaches about 150 kg / tHM, the material level of the gasification furnace is stabilized, 25 material levels before tapping are stabilized at 50%, 24 material levels after tapping are not smaller than 100%, and low material levels or long-term full material levels are completely eradicated; the coke foam is discharged from a 2500m < 3 > blast furnace, the particle size composition of 5-10mm is 60%, the particle size composition of the slack coal is 5-10mm and is kept above 50%, the moisture of the coke foam is less than 5%, and the moisture of the slack coal is less than 8%; the volatile matter of the slack coal is controlled to be greater than 35%, the gas generation amount is increased, and the fuel consumption is reduced.

Owner:XINJIANG BAYI IRON & STEEL

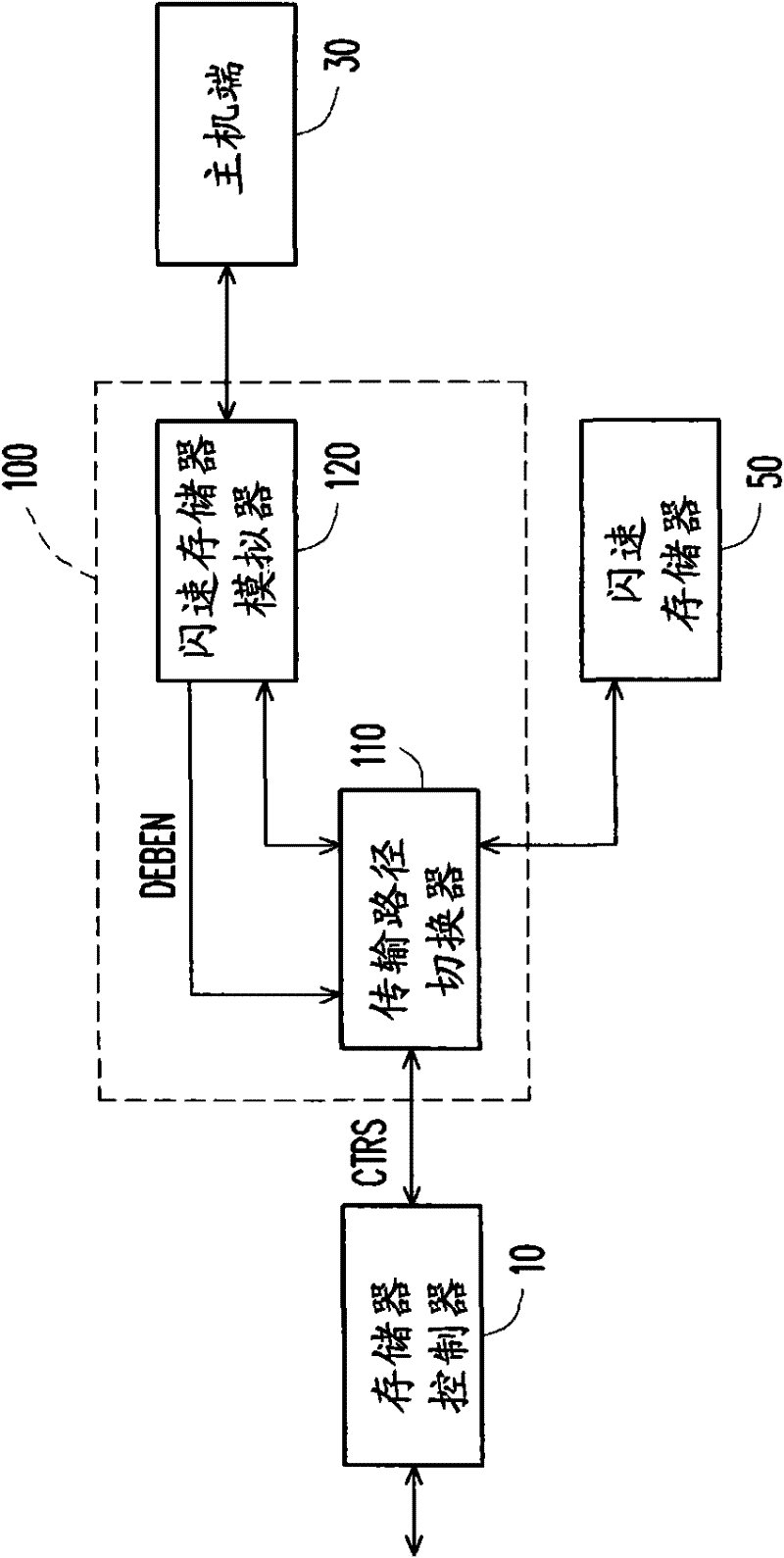

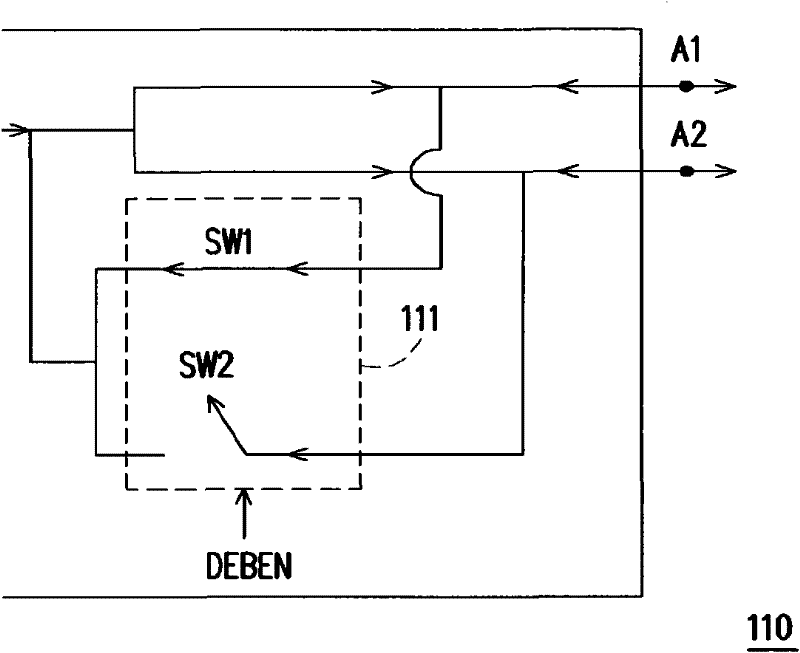

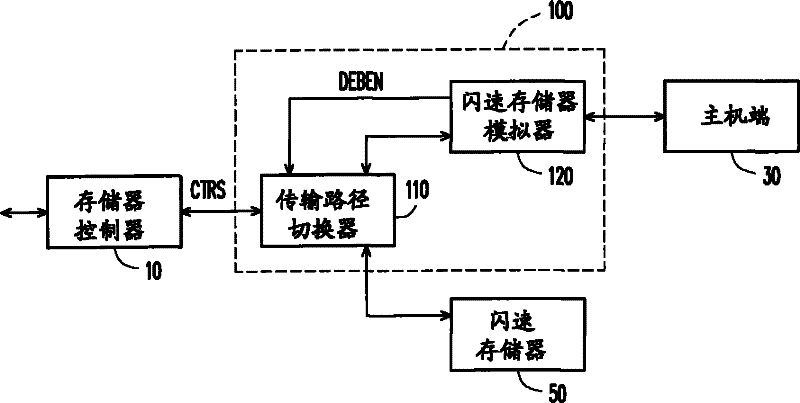

Flash memory development system

A flash memory development system comprises a transmission path switching device and a flash memory simulator. The transmission path switching device is connected in series between a memory controller and a signal transmission path of the flash memory and used for receiving debug startup signals. The flash memory simulator is used for receiving at least one control command from the memory controller through the signal transmission path. The flash memory simulator is used for interpreting and responding the control command to generate at least one simulation and response data. The flash memory simulator is also used for sending simulation and response data to the memory controller through the signal transmission path. The system can enhance cost competitiveness of products without expensive apparatuses or complicated method.

Owner:ASOLID TECH

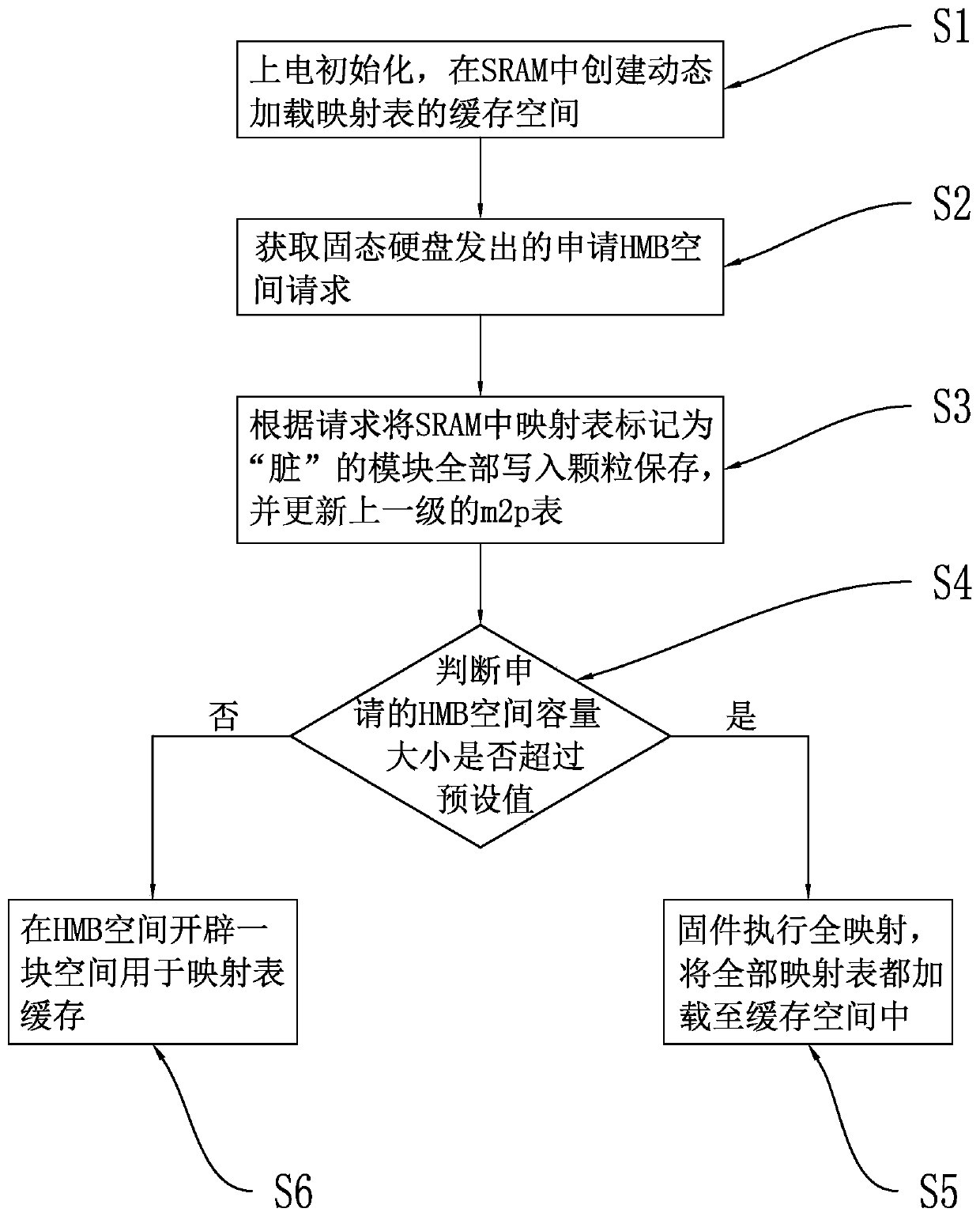

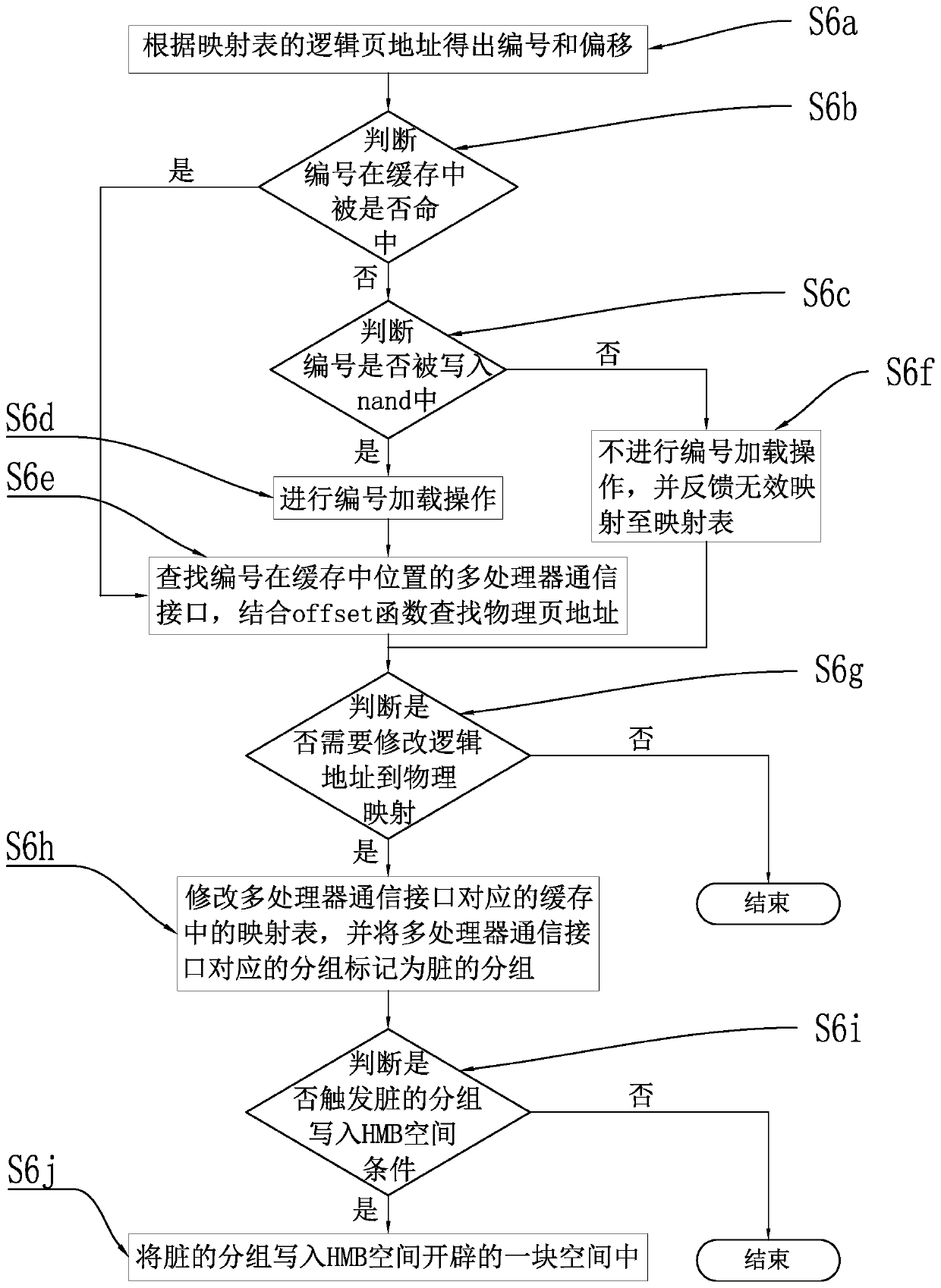

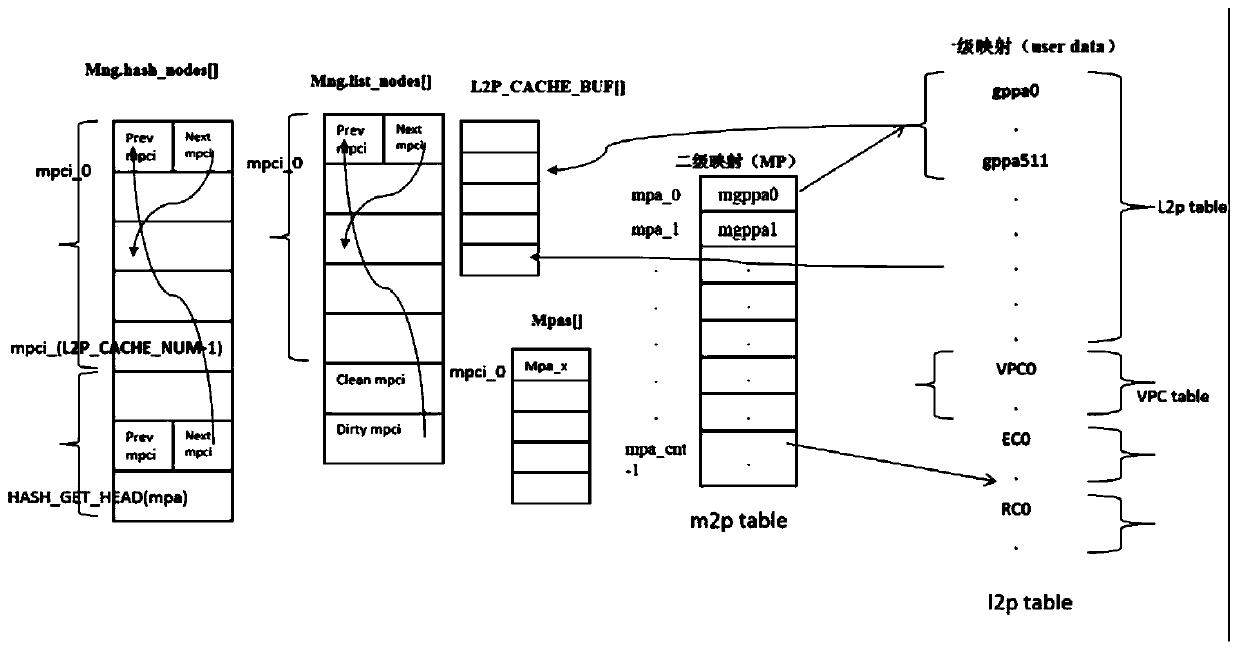

Implementation method and device of cache-free solid state disk, computer equipment and storage medium

The invention relates to an implementation method and device of a cache-free solid state disk, computer equipment and a storage medium. The method comprises the following steps of: performing electrifying and initializing, and creating a cache space for dynamically loading a mapping table in the SRAM; obtaining an HMB space application request sent by the solid state disk; writing all the modulesmarked as dirty in the mapping table in the SRAM into the particles for storage according to the request, and updating the m2p table of the previous level; judging whether the applied HMB space capacity exceeds a preset value or not; if yes, enabling the firmware to execute full mapping, and loading all mapping tables into the cache space; if not, opening up a space in the HMB space to be used formapping table caching. The acceleration of the solid state disk is realized, the DRAM cache of the current mainstream solid state disk is removed, the cost of the solid state disk is reduced, and thecost competitiveness of the product is improved.

Owner:SHENZHEN YILIAN INFORMATION SYST CO LTD

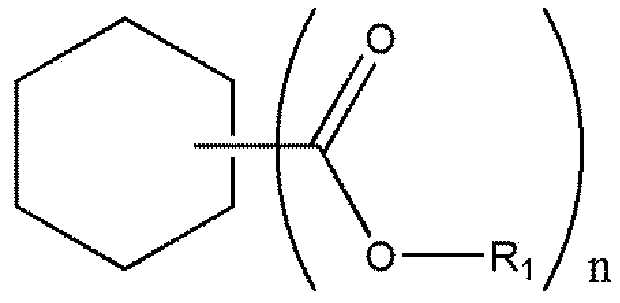

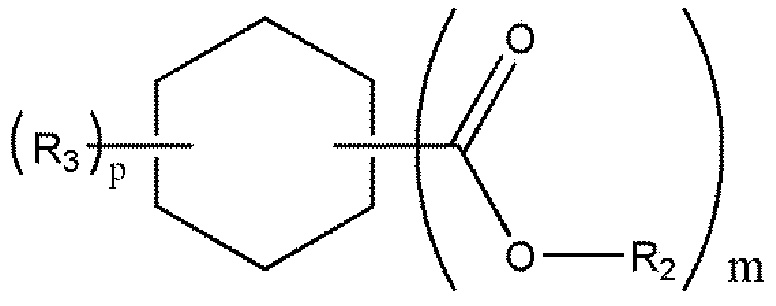

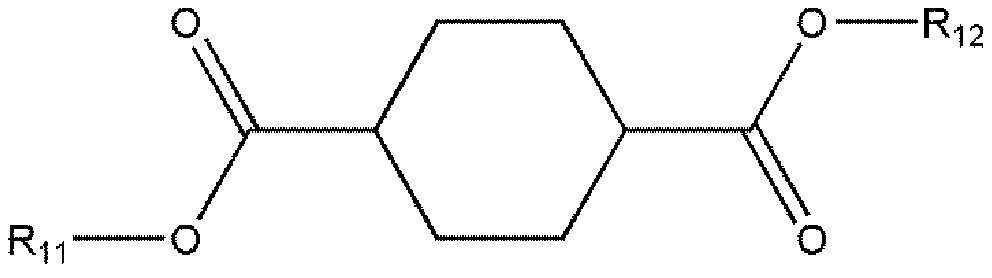

Plasticizer composition comprising cyclohexane polyester-based material, and resin composition comprising same

ActiveCN111491995AImprove thermal stabilityGuarantee friendlinessOrganic compound preparationCarboxylic acid esters preparationPolyesterPolymer science

The present invention relates to a plasticizer composition for reducing heat loss and for improving thermal stability, and, as mechanical properties, elongation and tensile strength by applying a cyclohexane polyester-based material as a plasticizer and applying, together therewith, a material, which has fewer ester groups than the cyclohexane polyester-based material, as a peroxide.

Owner:LG CHEM LTD

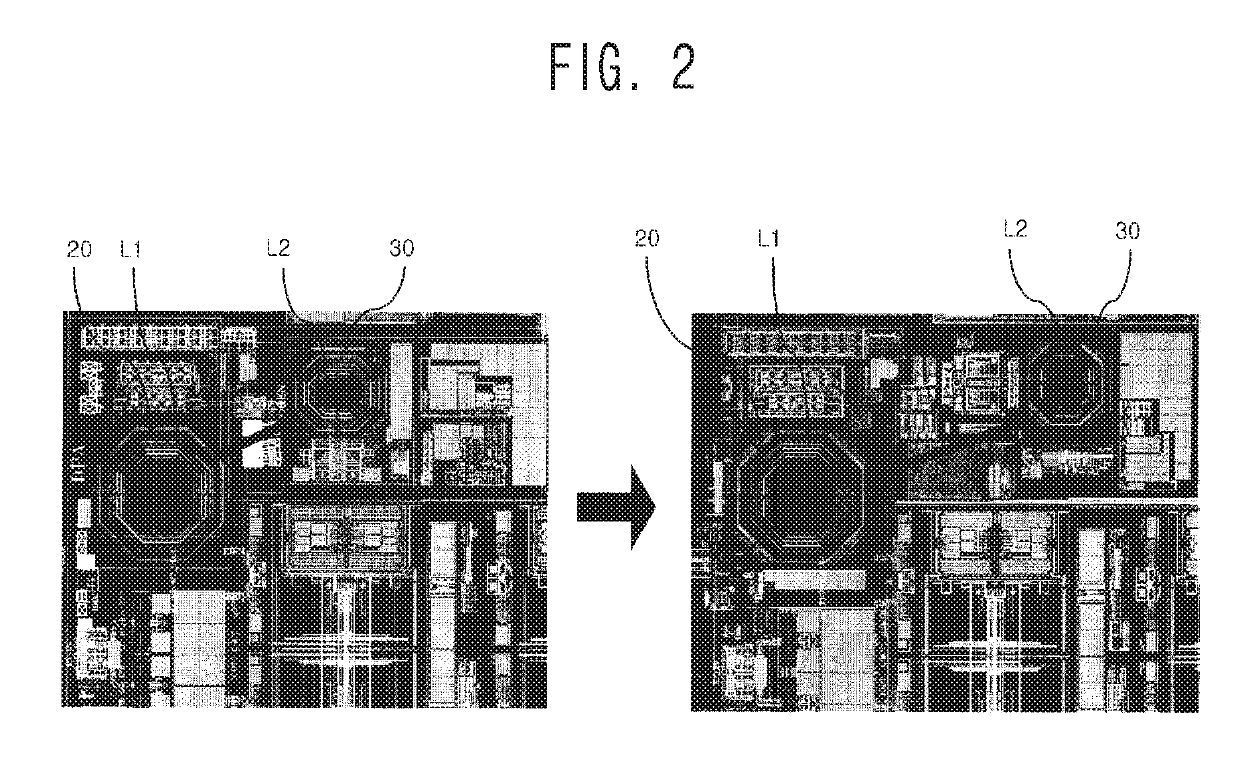

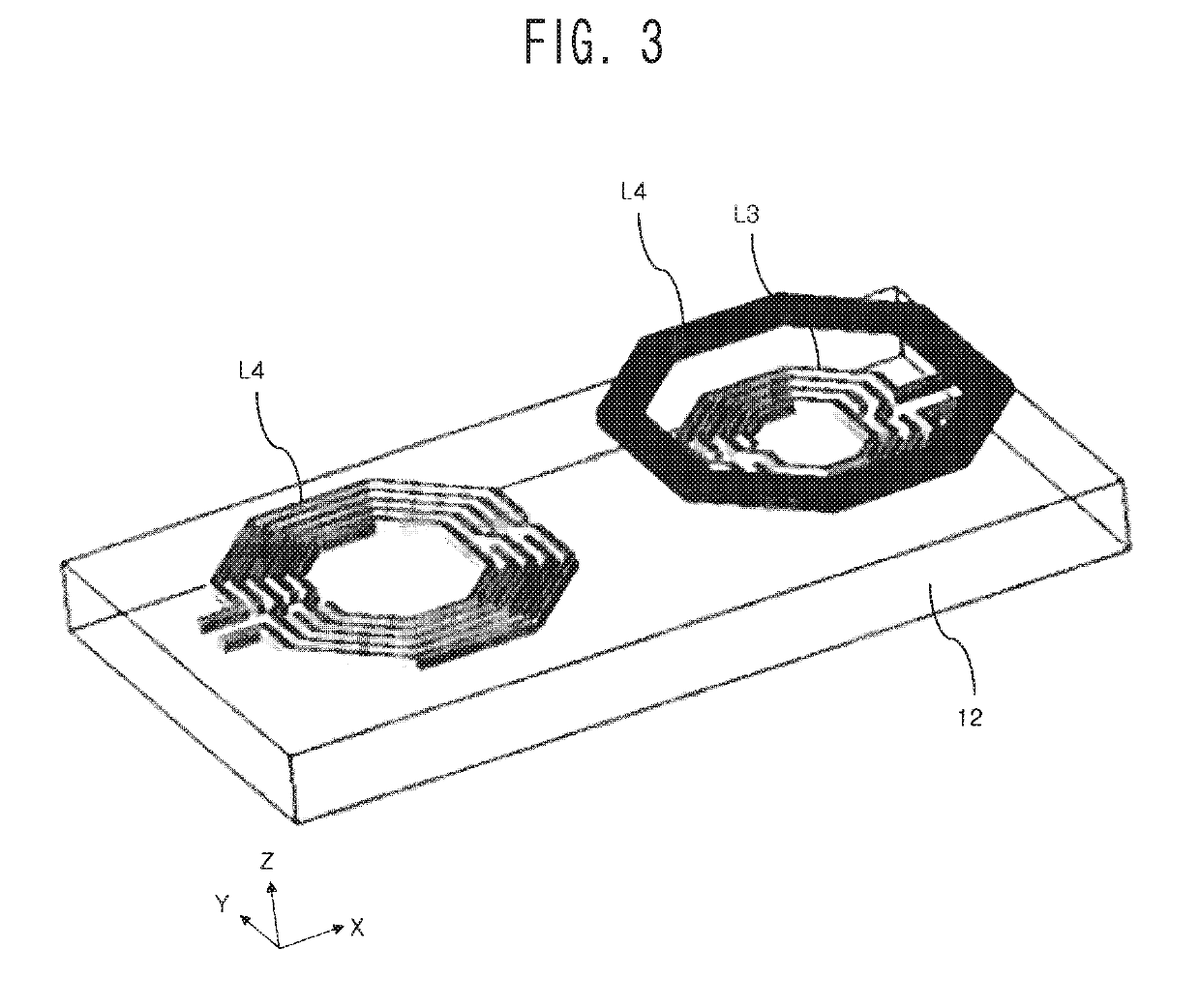

Inductor layout having improved isolation through blocking of coupling between inductors, and integrated circuit device using same

InactiveUS20190180931A1Reduce areaMiniaturizeNear-field transmissionNegative-feedback-circuit arrangementsElectrical conductorRFIC

Disclosed are an inductor layout and an integrated circuit device with improved isolation between inductors through shielding magnetic coupling between the inductors. first and second inductor coils are horizontally spaced apart from each other. A conductor loop is disposed in parallel above the first inductor coil and shields magnetic coupling between the first and second inductor coils in the manner that a part of magnetic flux of a first time-varying magnetic field generated by the second inductor coil is cancelled by magnetic flux of a second magnetic field generated by an induction current that flows in the conductor loop magnetically interlinked with the first time-varying magnetic field. The inductor layout can be applied to an RFIC device to reduce magnetic coupling between inductors of a power amplifier and an oscillator. Improved performance of the device and a very small RFIC can be achieved.

Owner:KOREA ADVANCED INST OF SCI & TECH +1

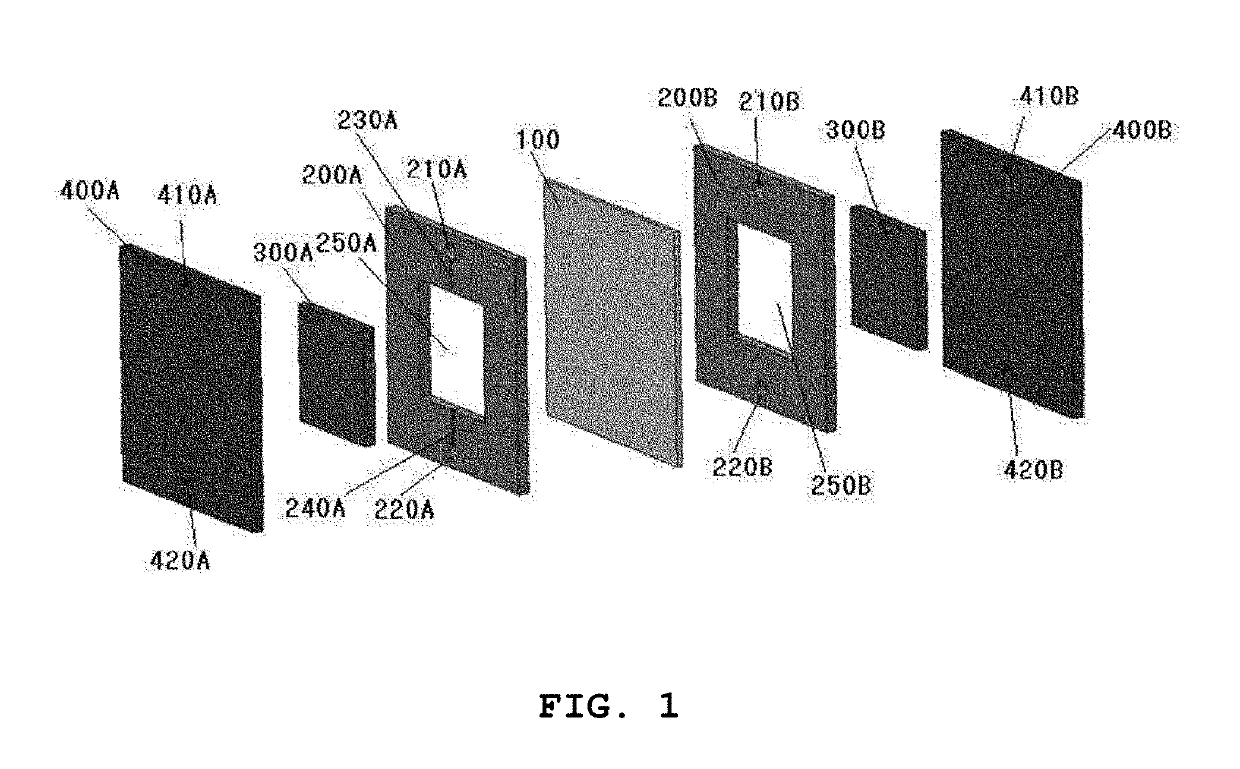

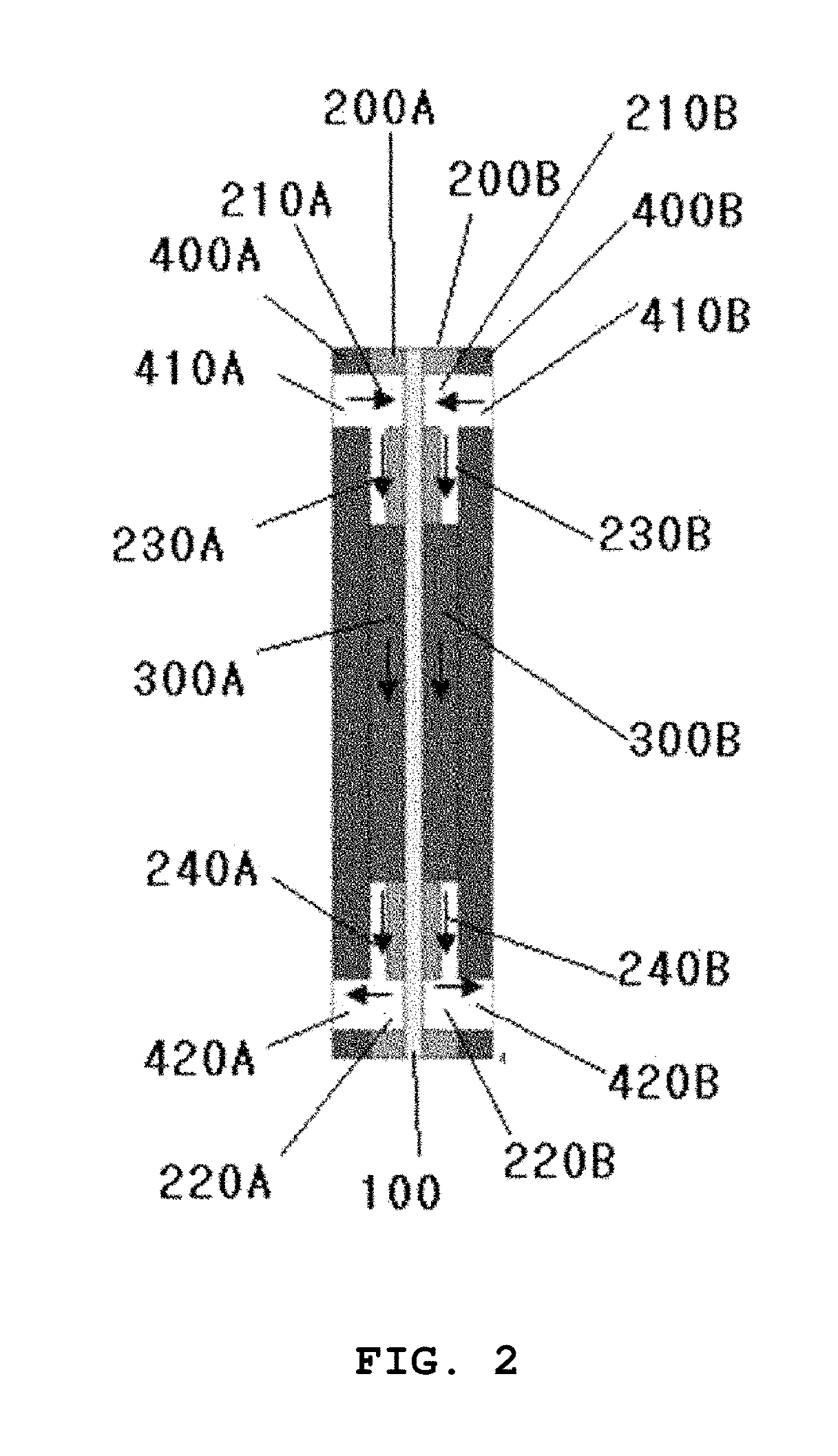

Unit cell for redox flow battery, for reducing pressure drop caused by electrolyte flow in stack

ActiveUS20190165385A1Lower overall pressure dropReduce power consumptionRegenerative fuel cellsRedoxIon-exchange membranes

Provided is a redox flow battery stack comprising: an ion-exchange membrane (1000); two flow frames (2000A, 2000B) disposed on both sides of the ion-exchange membrane (1000), respectively; two bipolar plates (4000A, 4000B) disposed outside the flow frames (2000A, 2000B), respectively; and electrodes disposed in cavities inside outer frames of the flow frames (2000A, 2000B), respectively, in which at least two electrodes are disposed in the flow frames, respectively, and at least three furrows in which the electrolyte flows are formed between electrodes or between the electrode and the outer frame in the flow frame.

Owner:H2 METAL

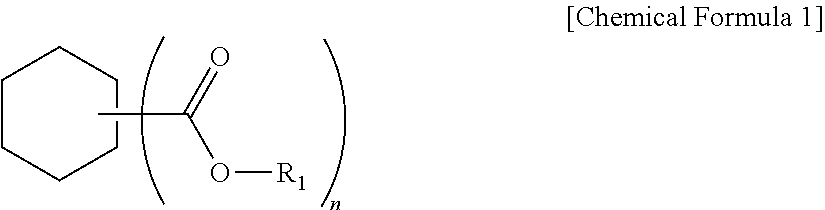

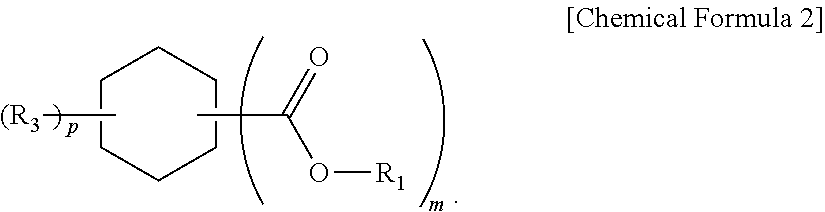

Plasticizer composition comprising cyclohexane polyester-based substance and resin composition comprising the same

PendingUS20210070965A1Improve mechanical propertiesImprove thermal stabilityOrganic compound preparationCarboxylic acid esters preparationPolyesterPolymer science

Provided is a plasticizer composition comprising a cyclohexane polyester-based substance which is a compound of Chemical Formula 1 as a plasticizer:in combination with a perhydride comprising a compound of Chemical Formula 2 having a smaller number of ester groups than the cyclohexane polyester-based substance:Also provided are resin compositions containing the plasticizer composition and methods of preparing the plasticizer composition.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com