Component defect monitoring and prediction system based on TLS (Terrestrial Laser Scanning)

A technology for predicting systems and components, applied in the field of measurement, can solve the problems of manual extraction, labor and time consumption, etc., and achieve the effects of cost competitiveness improvement, good compatibility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

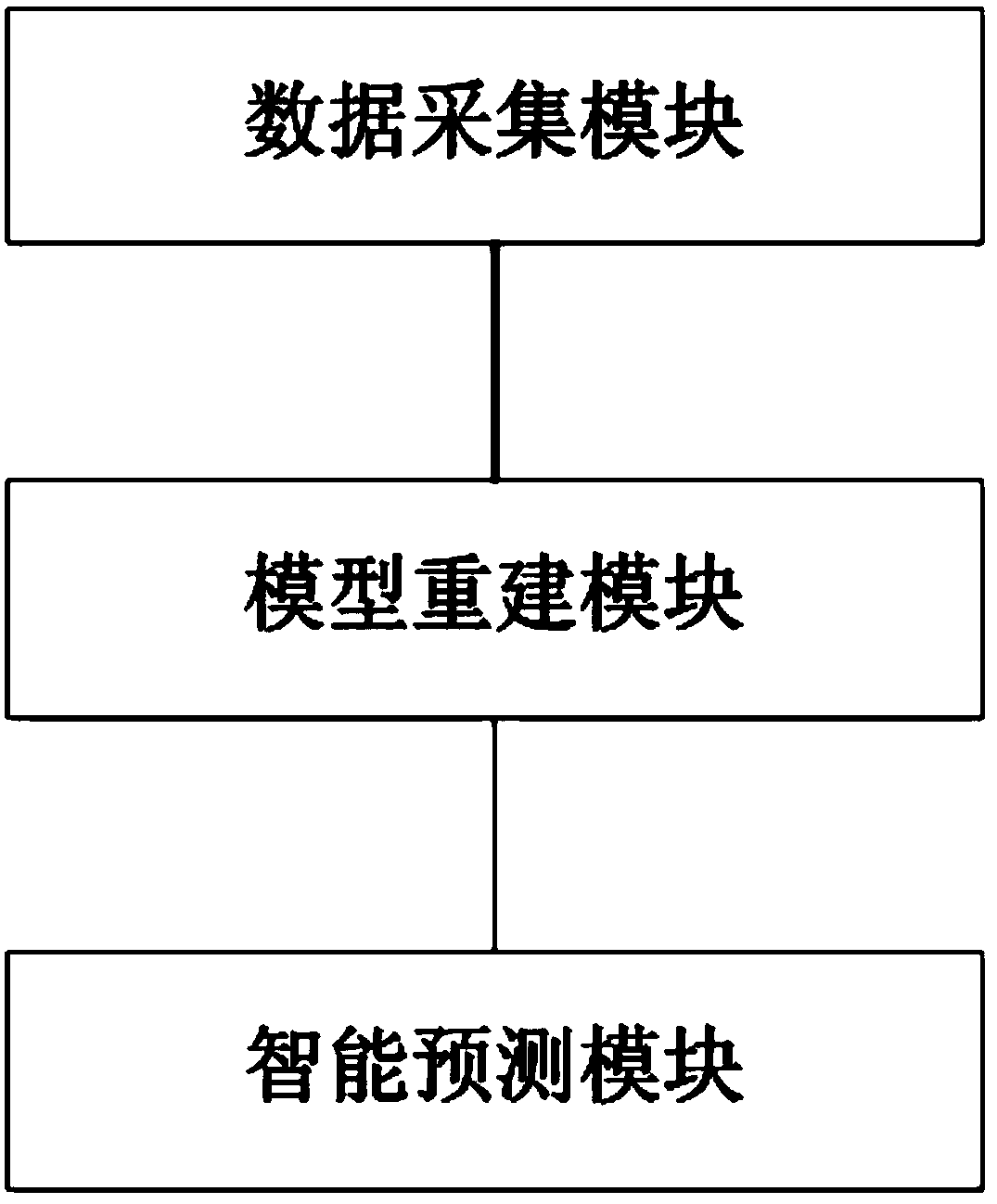

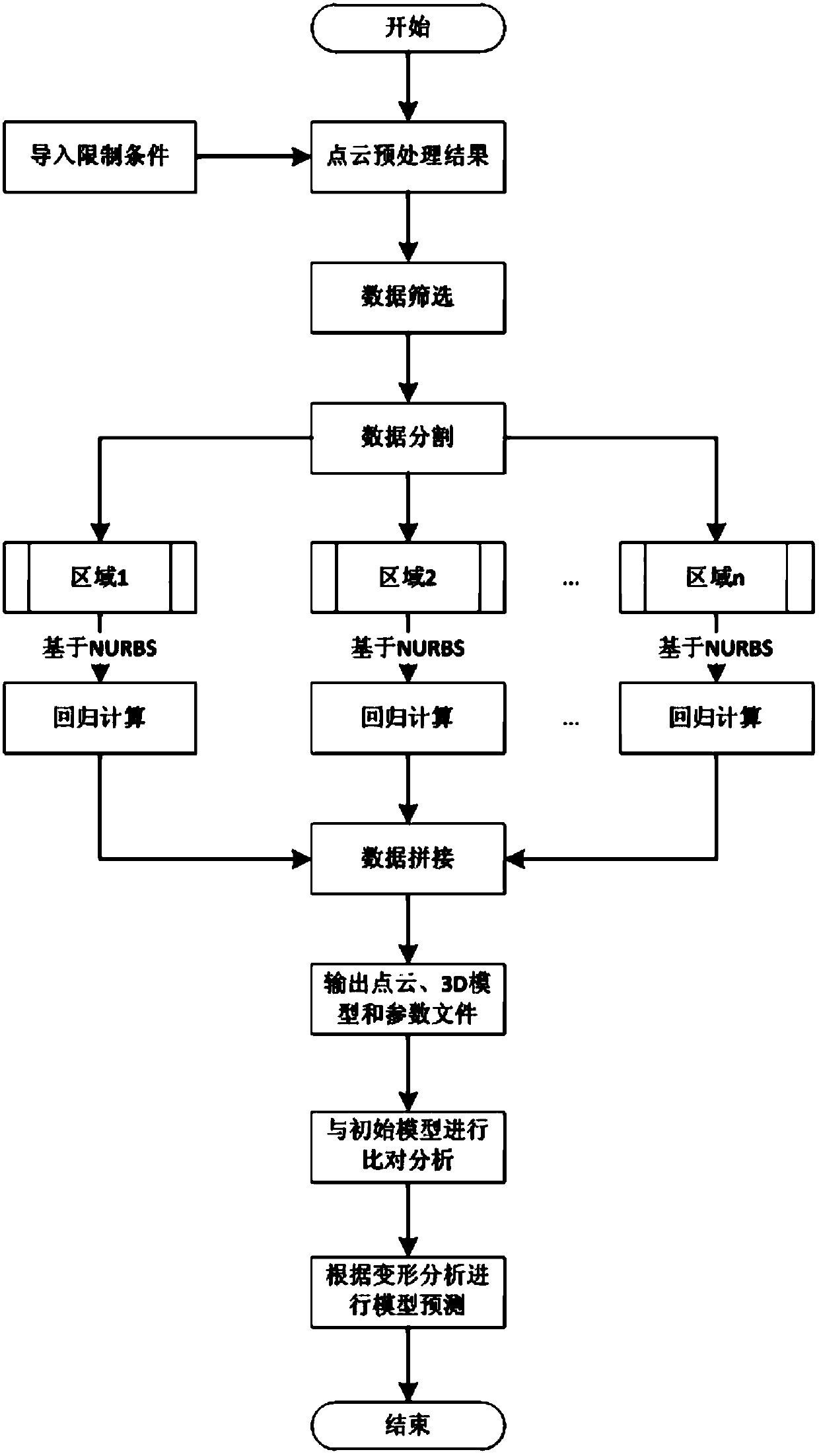

[0055] Such as figure 1 As shown, the present invention provides a structural health monitoring and intelligent prediction system based on TLS (Terrestrial Laser Scanning, TLS for short) technology, including three modules of data acquisition, model reconstruction and intelligent prediction.

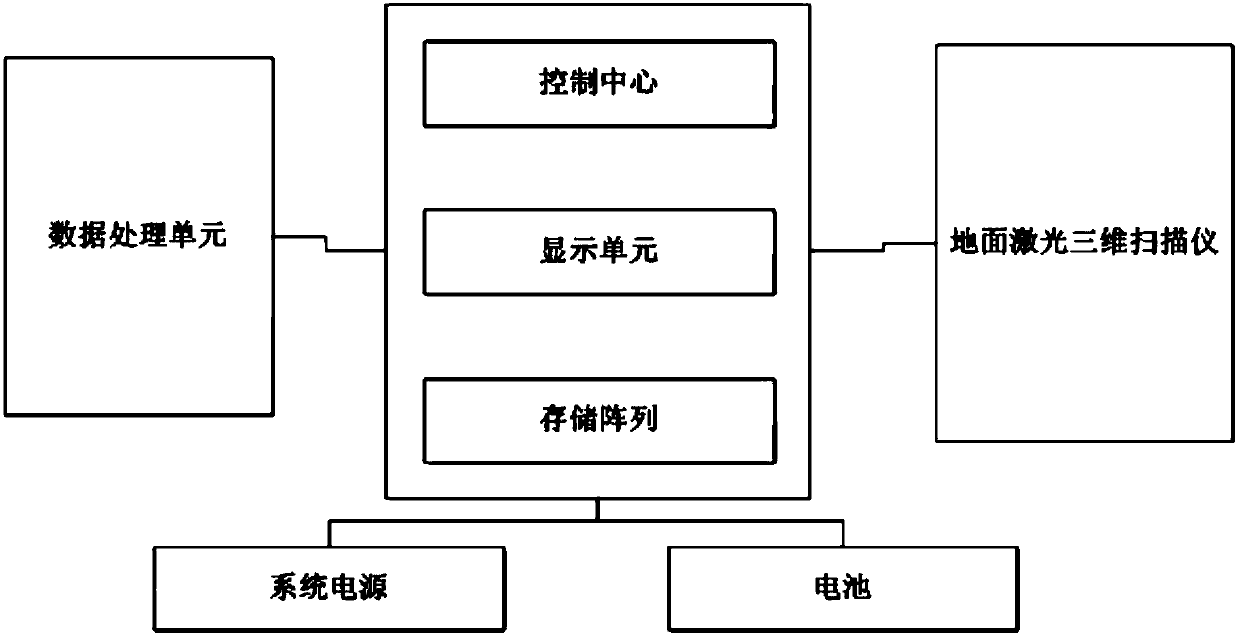

[0056] Such as figure 2 As shown, in terms of hardware architecture, the 3D laser scanner is connected to the control center, and the data processing unit processes the data acquired by the 3D laser scanner and stores it in the storage array, and displays the processing results and modeling results on the display of the control center. and forecast targets. In order to ensure the normal operation of the control center, it is equipped with batteries and system power supply to ensure stable operation. The three-dimensional laser scanner can be a high-speed laser scanning device with a full circle, a rotation frequency of more than 100 revolutions per second, and a scanning point through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com