Method for reducing process energy consumption of European smelting furnace

A technology of energy consumption and process, which is applied in the field of reducing energy consumption of Ouye furnace process, and can solve the problems of high pressure on emission reduction and energy saving, and failure to achieve it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: a method for reducing the energy consumption of the Ouye furnace process,

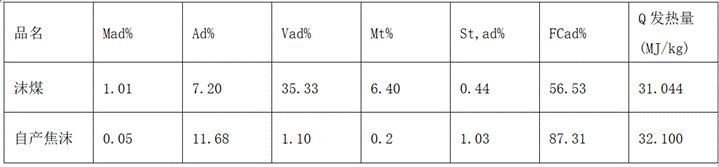

[0018] 1. One of the conditions for the smooth operation of the Ouyeel furnace is to maintain the smooth flow of the furnace while taking into account the economy, especially the straight flow of the shaft furnace is particularly important. According to the existing ore resource conditions of the Bayi Iron and Steel Plant, the use of acid pellets with high Basicity sintered ore, according to the cost performance and economy of ore smelting, the best ore mix structure suitable for the furnace charge structure of Ouyeel furnace reduction furnace is obtained as follows:

[0019]

[0020] Improve the compressive strength of pellets to make the compressive strength greater than 2200N. The composition of sinter is stable, the basicity of sinter is stable at R=2.4 times, MgO: 2.4%, and the conversion of shares is more than 80%.

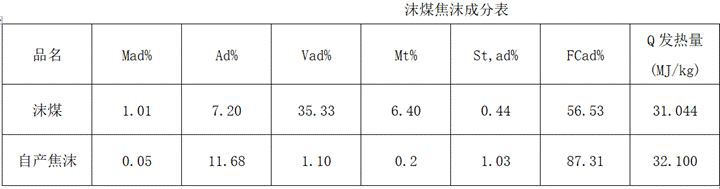

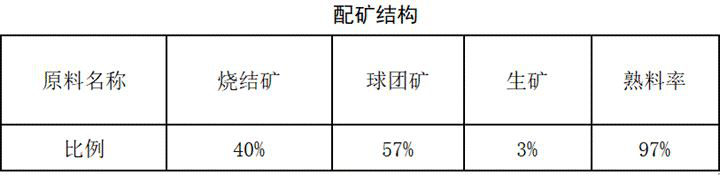

[0021] 2. Low coke ratio operation structure and fuel par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com