Soft magnetic powder compound, core and electric reactor

A soft magnetic and composite technology, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., to achieve the effects of easy operation, suppressing noise, and suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0067] (1) Soft magnetic powder

[0068] As the soft magnetic powder, sendust (Fe—Si—Al alloy) powder, Fe—Si alloy powder, pure iron powder, or the like can be used.

[0069] In addition, FeBPN (N is one or more elements selected from Cu, Ag, Au, Pt, and Pd) can be used as the soft magnetic powder. As the soft magnetic powder, those produced by a water atomization method, gas atomization method, or water-gas atomization method can be used, and those produced by a water atomization method are particularly preferable. The reason is that in the water atomization method, crystallization is difficult due to rapid cooling during atomization.

[0070] The average particle diameter of the soft magnetic powder is preferably 20 μm to 100 μm. The powder hardness (pressure required for 10% displacement) of the soft magnetic powder is preferably 100 MPa or more. For example, the powder hardness of amorphous alloy is 700 MPa, the powder hardness of Fe-6.5% Si alloy is 390 MPa, and the po...

Embodiment approach 2

[0101] The same soft magnetic powder, hardening accelerator, binder resin, and lubricating resin as in Embodiment 1 are used.

[0102] The condensed phosphoric acid metal compound uses the same material as in Embodiment 1. In the present embodiment, the added amount of the condensed phosphoric acid metal compound is preferably 0.20% by weight to 0.80% by weight relative to the soft magnetic powder.

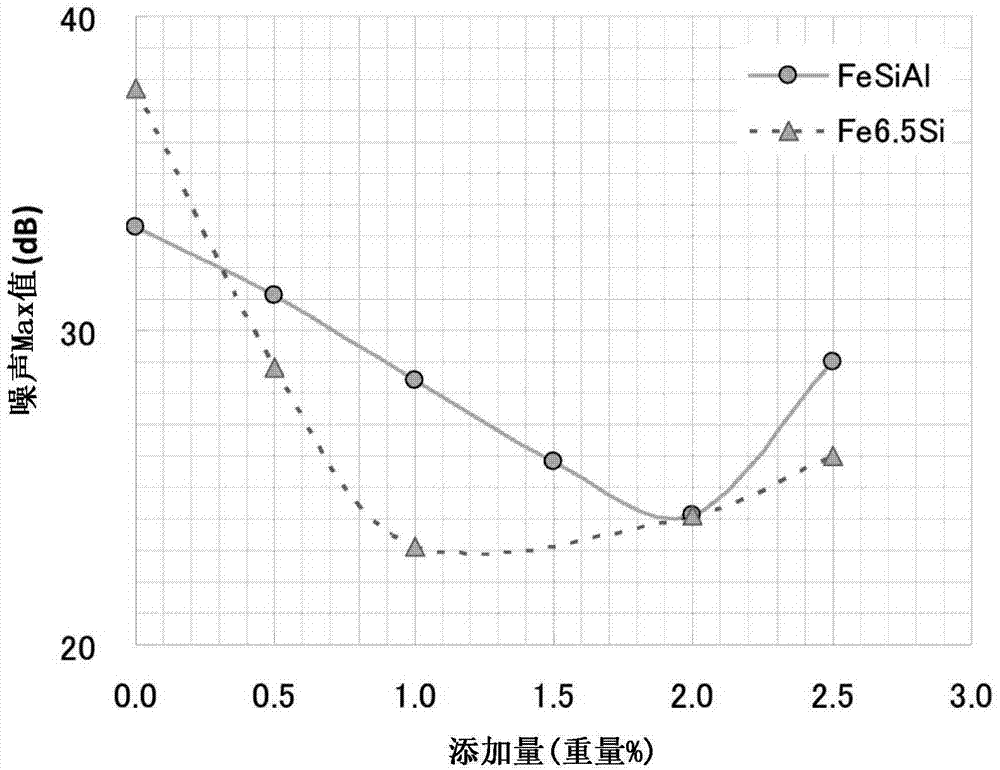

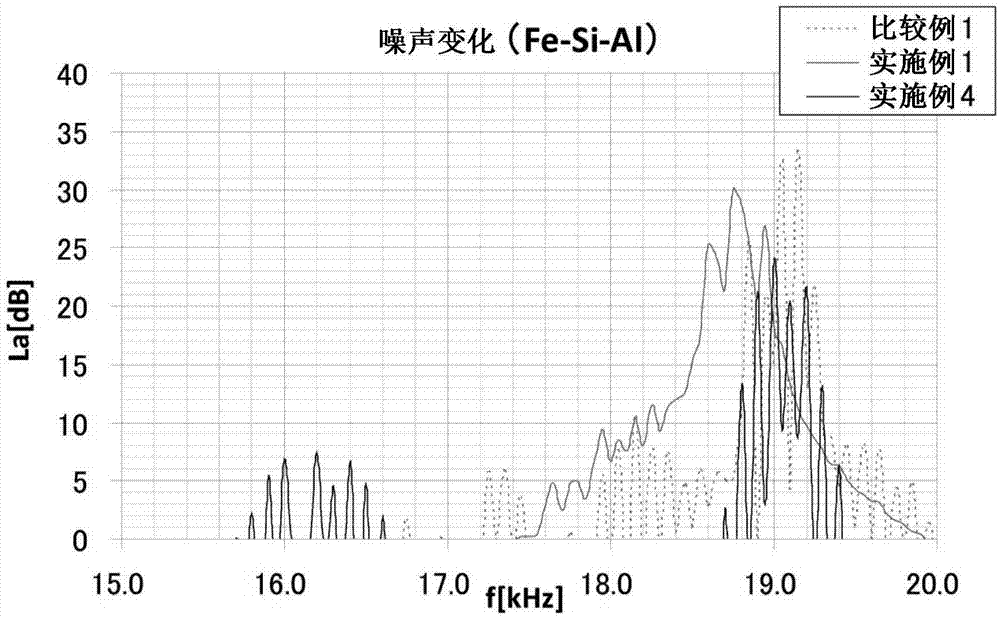

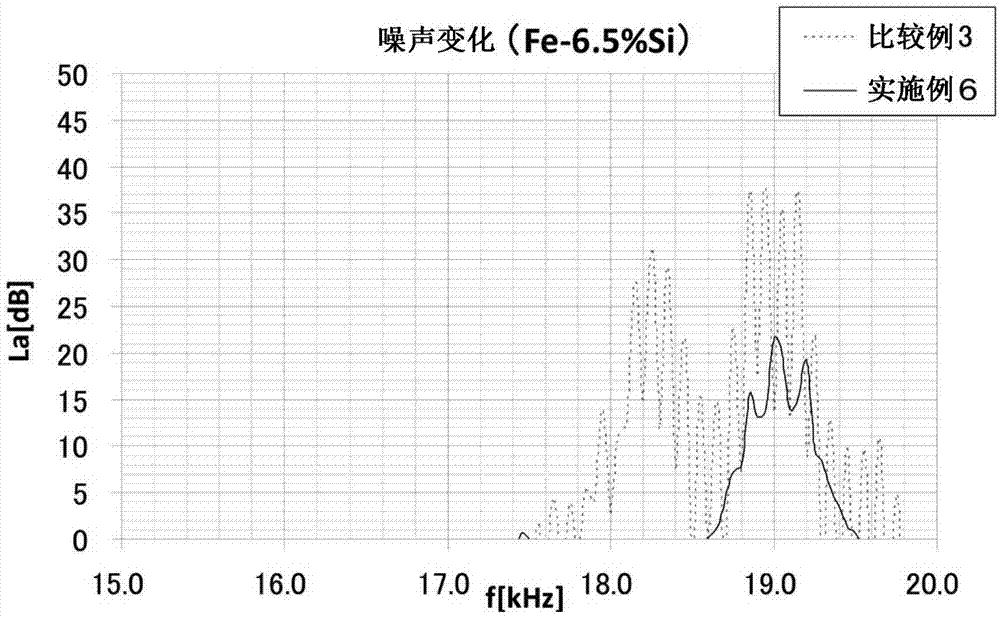

[0103] In this embodiment, by further adding insulating fine powder, it is possible to prevent adhesion between the soft magnetic powders, to harden the insulating layer around the soft magnetic powder, to suppress vibration of the soft magnetic powder, and to obtain a noise suppression effect. From the viewpoint of the noise suppression effect, the average particle diameter of the insulating fine powder is preferably 7 nm to 1 μm. More preferably, it is 7 nm to 500 nm. As insulating fine powder, alumina powder (Al 2 o 3 ), SiO 2 , MgO, etc. In addition, the higher the hardn...

Embodiment approach 3

[0107] The same soft magnetic powder, hardening accelerator, binder resin, and lubricating resin as in Embodiment 1 are used.

[0108] The condensed phosphoric acid metal compound uses the same material as in Embodiment 1. In the present embodiment, the added amount of the condensed phosphoric acid metal compound is preferably 0.25% by weight to 2.0% by weight relative to the soft magnetic powder. When the added amount is more than 0.25% by weight, the effect of increasing the strength of the produced core can be obtained; when the added amount exceeds 2.0% by weight, the density of the core decreases and the strength also decreases.

[0109] The manufacturing method is the same as that of Embodiment 1. In the present embodiment, the step of heat-treating the molded body is performed in a non-reducing atmosphere such as an air atmosphere. As the non-reducing atmosphere, in addition to the air, an inert gas atmosphere such as 100% nitrogen may be used. For example, the molde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com