Method for producing white sugar, light brown sugar and dark brown sugar using direct recovery process

A technology for yellow granulated sugar and white sugar is applied in the field of preparing white sugar, yellow granulated sugar and brown sugar, which can solve the problems of reducing production cost and imposing restrictions, and achieves the effect of reducing equipment investment and increasing cost competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

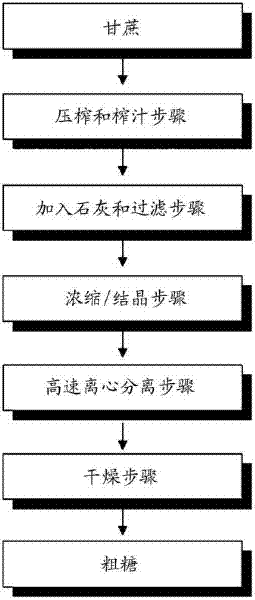

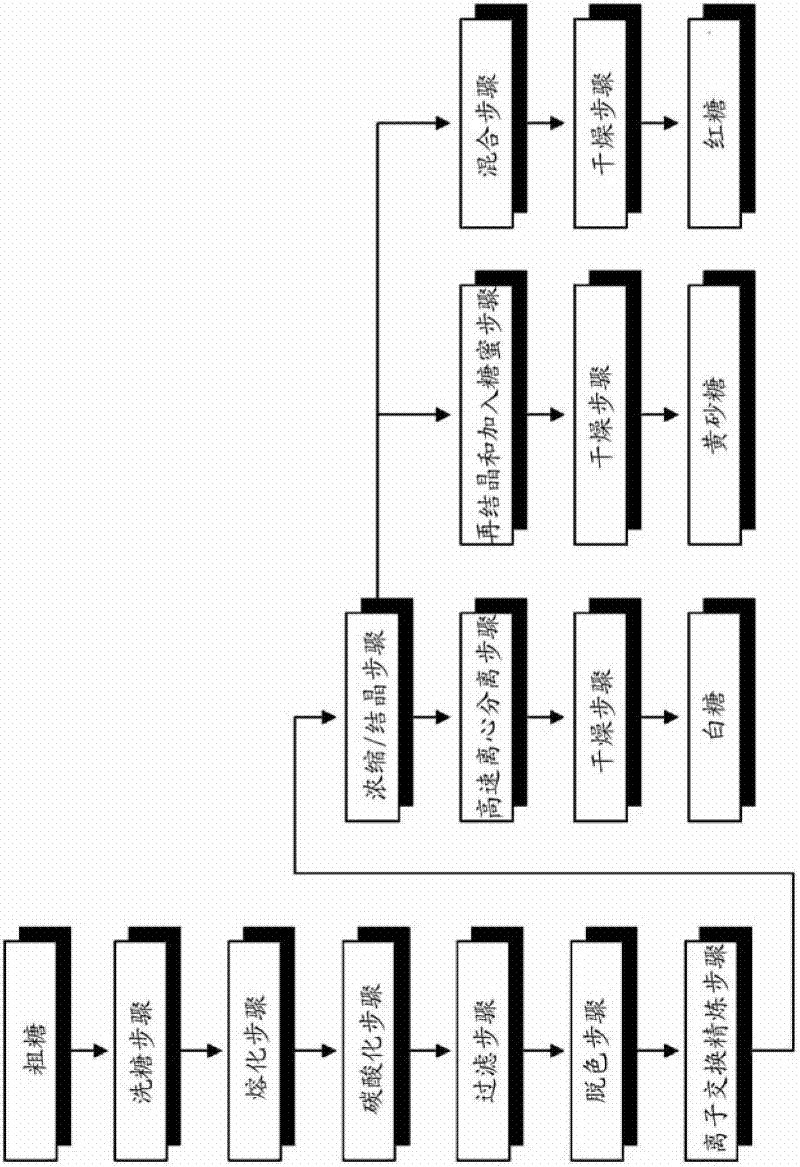

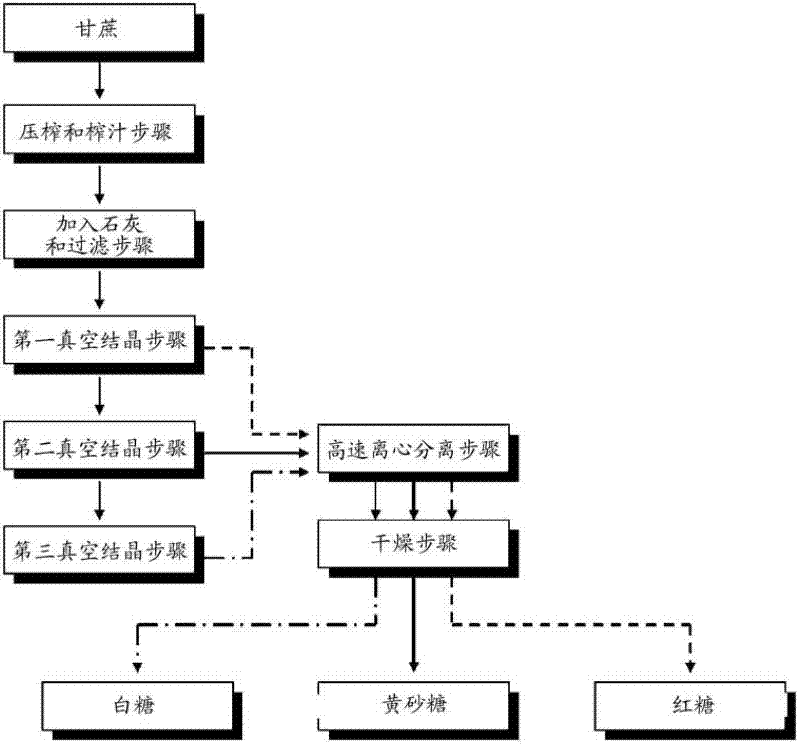

[0042] In the following, reference will be made to image 3 with Figure 4 The preparation method of the present invention is described in detail. Such as image 3 As shown, the method for preparing white sugar, brown sugar and brown sugar according to the present invention includes the steps of pressing and squeezing sugarcane to extract the juice, the steps of adding lime and filtering, the first vacuum crystallization step, the second vacuum crystallization step, the second Three vacuum crystallization steps, a high-speed centrifugal separation step and a drying step. also, Figure 4 The general scheme of the preparation method according to the present invention is shown in .

[0043] Step 1 of the preparation method according to the present invention is a pressing and juicing step: pressing and juicing sugarcane to extract sugarcane juice. In this step, the sugarcane cut to a given size is placed in a conventional press and / or juice extractor where the juice is extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com