Sintering device and sintering method using induction heating

A technology of a sintering device and a sintering method, which is applied to lighting and heating equipment, process efficiency improvement, furnace components, etc., can solve problems such as increasing flame propagation speed, environmental pollution, etc., and achieve the effect of reducing the amount of coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] First of all, it should be noted that when adding reference numerals to components of each figure, the same reference numerals are given to the same components as much as possible although they are indicated on other figures. Also, in describing the present invention, detailed descriptions of known functions and structures incorporated herein will be omitted to avoid obscuring the subject matter of the present invention.

[0044] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

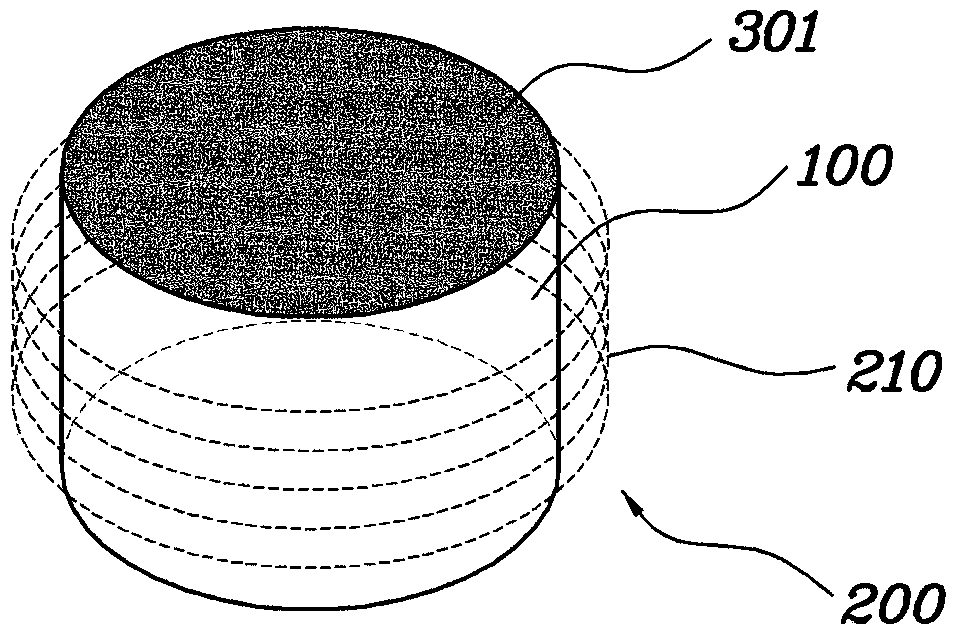

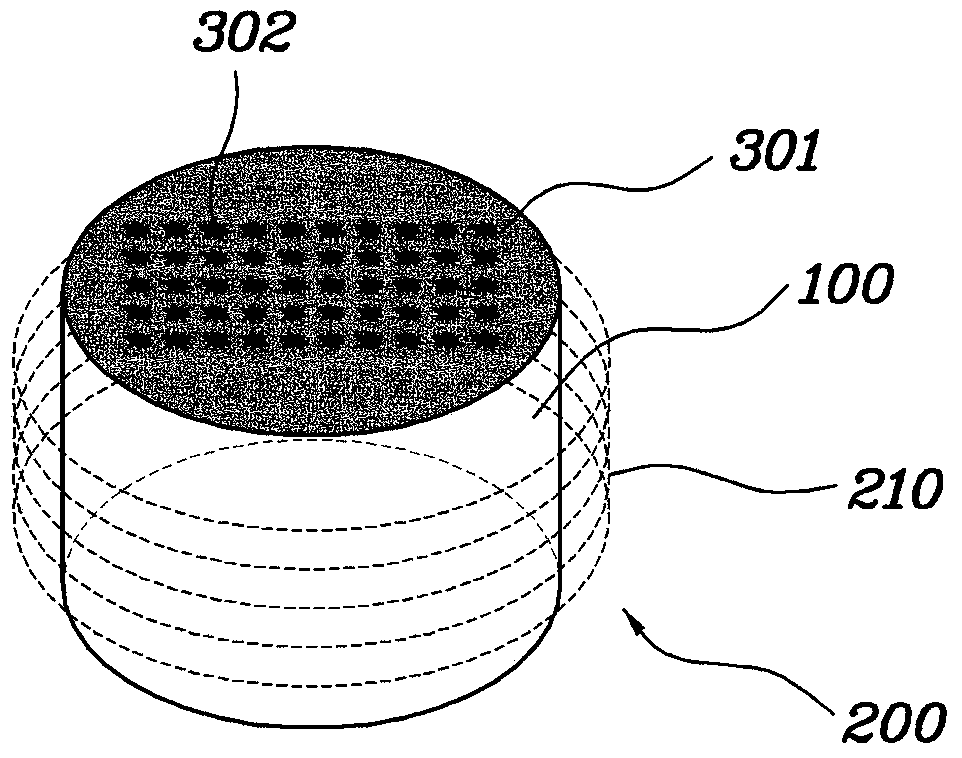

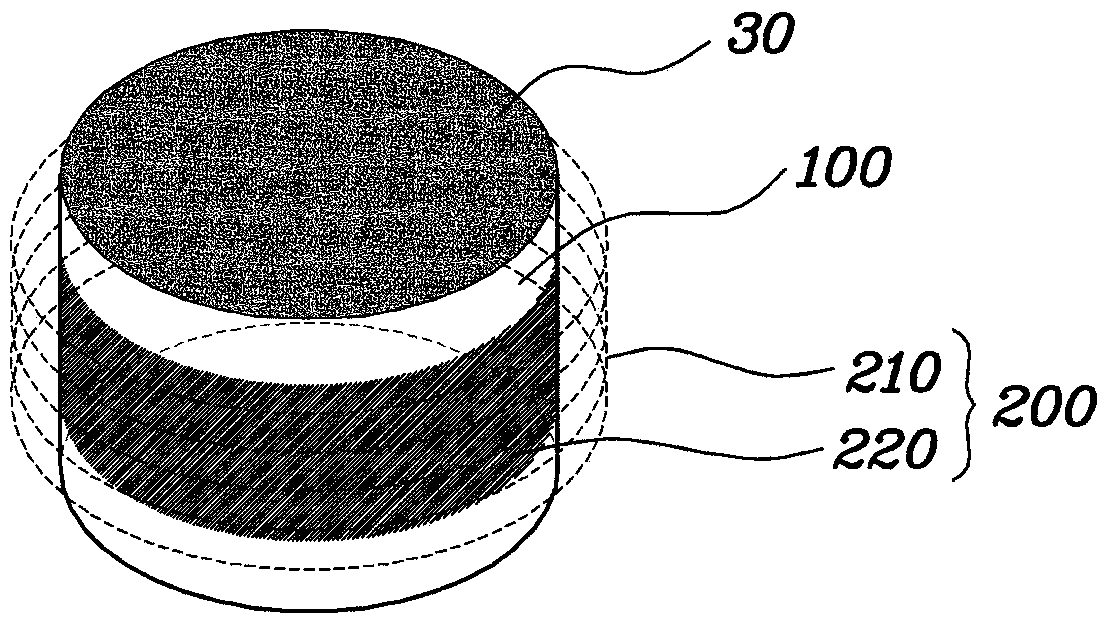

[0045] figure 1 with figure 2 A sintering apparatus using induction heating according to a first embodiment of the present invention is shown.

[0046] The sintering apparatus and method using induction heating according to the present invention induces heating of a highly conductive material included in coke ore through magnetic induction using a change in a magnetic field so that the coke ore is sintered. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com