Method for producing pellets from laterite-nickel ore

A technology of lateritic nickel ore and pellet ore, which is applied in the field of ferronickel production technology, can solve the problems of large investment and complex application of technology and technology, and achieve the effect of good physical properties, low exploration cost and high nickel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

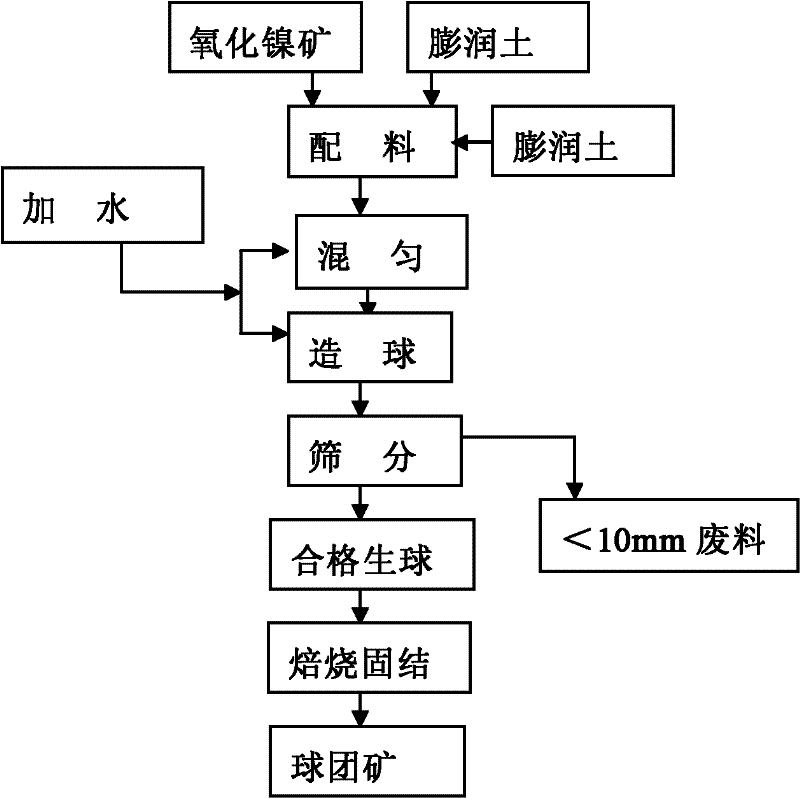

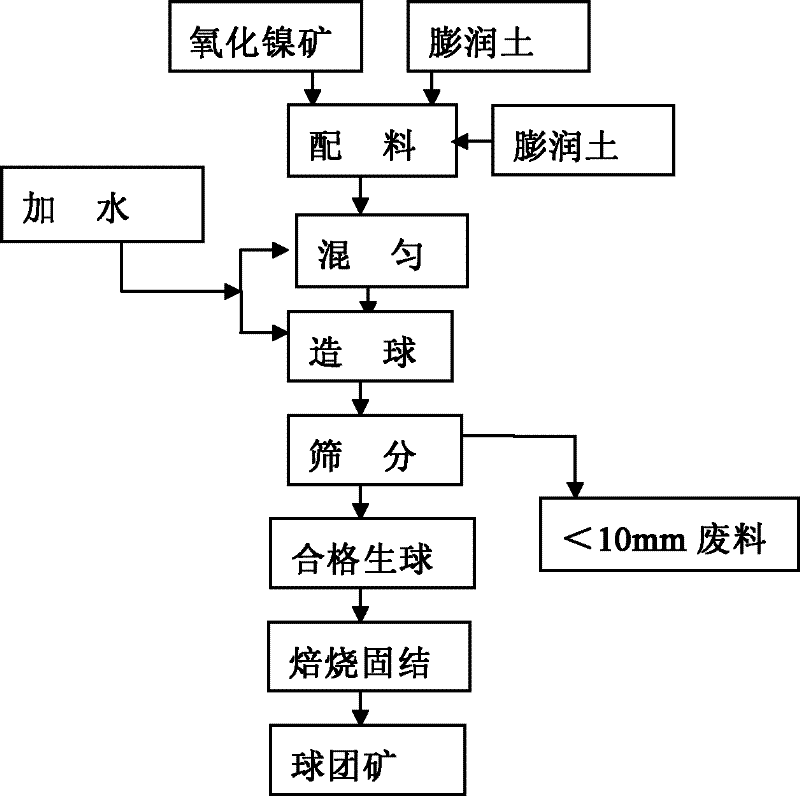

Image

Examples

Embodiment 1

[0039] The method for producing pellets from laterite nickel ore comprises the following steps, the first step, batching, including: bentonite with a mass fraction of 1%, quicklime at 1%, and nickel oxide at 98%; Add water to the mixed mixture in the first step until the water content is 10%, and then use a pelletizing machine to make pellets; the third step is to sieve and remove the raw materials with a particle size of less than 10mm to obtain qualified green pellets; the fourth step is to roast and solidify The knot is roasted at a temperature of 1300±100° C. for 60 minutes; the fifth step is to lower the temperature to obtain nickel pellets.

Embodiment 2

[0041] The method for producing pellets from laterite nickel ore comprises the following steps, the first step, batching, including: bentonite with a mass fraction of 4%, quicklime at 3%, and nickel oxide at 93%; Add water to the mixed mixture in the first step until the water content is 15%, and then use a pelletizer to make pellets; the third step is to sieve and remove the raw materials with a particle size of less than 10mm to obtain qualified green pellets; the fourth step is to roast and solidify The knot is roasted at a temperature of 1300±100° C. for 60 minutes; the fifth step is to lower the temperature to obtain nickel pellets.

Embodiment 3

[0043] The method for producing pellets from lateritic nickel ore comprises the following steps, the first step, batching, including: bentonite with a mass fraction of 2%, quicklime at 8%, and nickel oxide at 10%; Add water to the mixed mixture in the first step until the moisture content is 13%, and then use a pelletizer to make pellets; the third step is to sieve and remove the raw materials with a particle size of less than 10 mm to obtain qualified green pellets; the fourth step is to roast and solidify The knot is roasted at a temperature of 1300±100° C. for 60 minutes; the fifth step is to lower the temperature to obtain nickel pellets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com