Broiler chick feed and preparation method thereof

A technology for broiler chickens and feed, which is applied to the field of broiler chicken feed and its preparation, and can solve the problems of chicken breeding and food safety hazards, endangering human health, residues and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

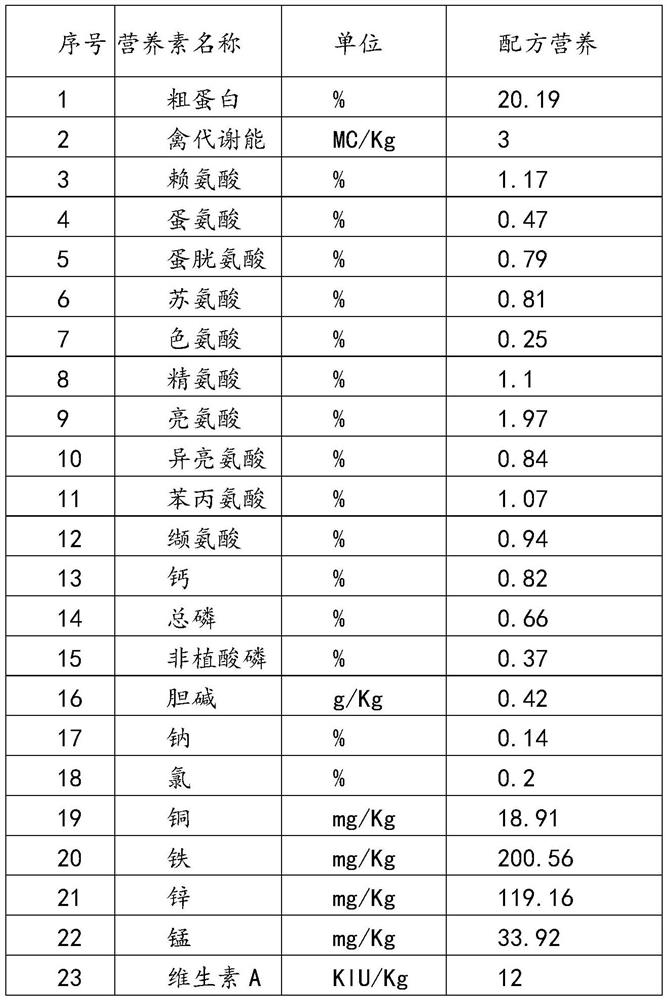

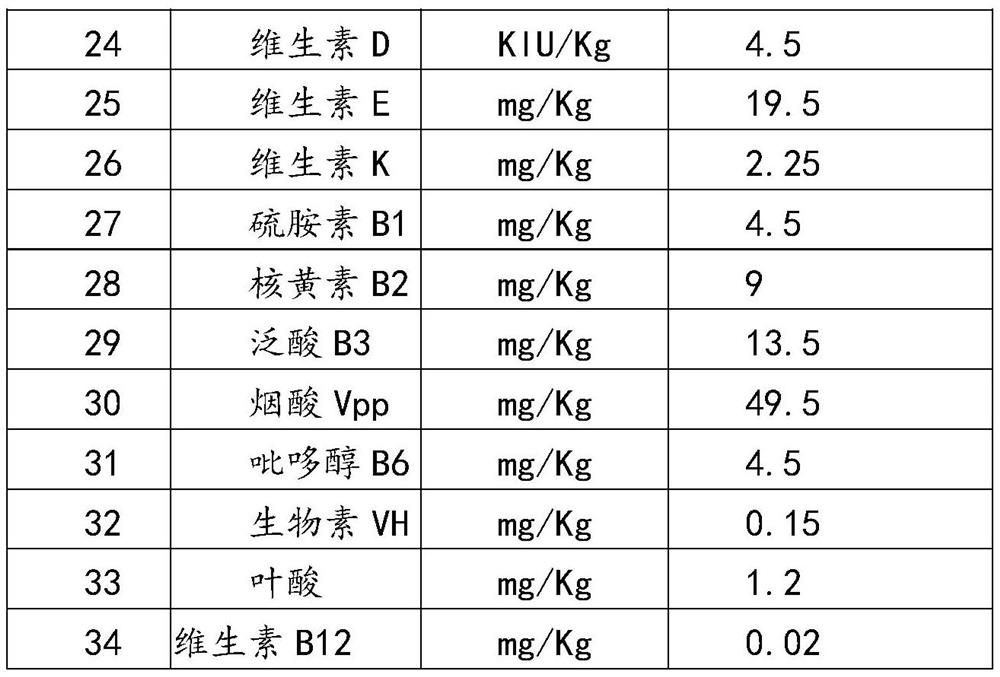

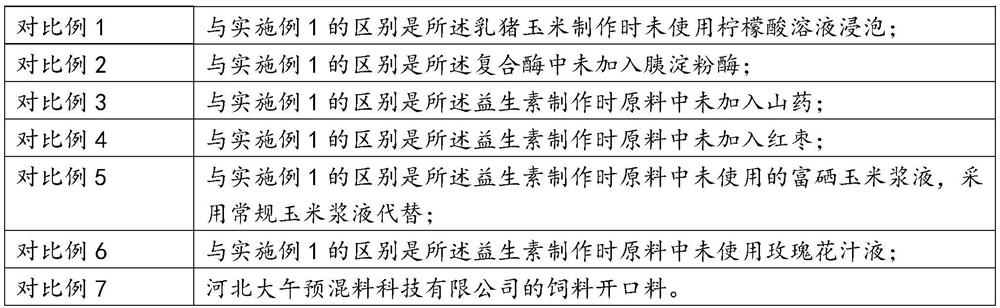

[0023] A feed for broilers and chicks, which consists of the following components by weight percentage: 59.70% of suckling pig corn, 22.00% of soybean meal, 5.00% of expanded soybean, 4.00% of corn gluten meal, 2.50% of rice DDGS, and 3.00% of rice bran meal , calcium carbonate 1.21%, calcium hydrogen phosphate 1.30%, lysine 0.35%, methionine 0.13%, compound enzyme 0.03%, prebiotic 0.02%, compound vitamin 0.03%, compound trace element 0.10%, choline chloride 0.08%, Sodium chloride 0.25%, montmorillonite 0.30%; the preparation method of the suckling pig corn is as follows: soak the corn with a quality of 40% of its mass in citric acid solution for 20h, cook it with steam at 120°C for 1h, and pass it through a tablet press. Pressing into tablets and drying to obtain it; the mass fraction of the citric acid solution is 0.03%; the ripening rate of the suckling pig corn is 100%, and the starch conversion rate is 75%; the protein content of the soybean meal is 46%; the Rice DDGS is ...

Embodiment 2

[0033] A broiler chicken feed, the composition of the following components by weight percentage: 55% of suckling pig corn, 20% of soybean meal, 3% of expanded soybean, 2% of corn gluten meal, 2% of rice DDGS, 2% of rice bran meal, carbonic acid Calcium 1%, calcium hydrogen phosphate 1.2%, lysine 0.3%, methionine 0.1%, compound enzyme 0.01%, prebiotic 0.01%, multivitamin 0.01%, compound trace element 0.1%, choline chloride 0.05%, chloride Sodium 0.2%, montmorillonite 0.1%; the production method of the suckling pig corn is as follows: soak the corn with a quality of 40% in citric acid solution for 20h, cook it with steam at 120°C for 1h, and press it into tablets with a tablet machine. , dried to obtain; the mass fraction of the citric acid solution is 0.03%; the ripening rate of the suckling pig corn is 100%, and the starch conversion rate is 76%; the protein content of the soybean meal is 47%; the rice DDGS That is, rice distiller's grains, whose crude fiber content is 22%; the ...

Embodiment 3

[0040] A feed for broilers and chicks, which consists of the following components by weight percentage: 60% of suckling pig corn, 20% of soybean meal, 8% of expanded soybean, 2% of corn gluten meal, 3% of rice DDGS, 2% of rice bran meal, carbonic acid Calcium 1.5%, calcium hydrogen phosphate 1.2%, lysine 0.4%, methionine 0.1%, compound enzyme 0.05%, prebiotic 0.01%, compound vitamin 0.03%, compound trace element 0.1%, choline chloride 0.1%, chloride Sodium 0.2%, montmorillonite 0.5%; the production method of the suckling pig corn is as follows: soak the corn with a quality of 50% in citric acid solution for 20 hours, cook it with steam at 120°C for 3 hours, and press it into tablets with a tablet machine. , dried to obtain; the mass fraction of the citric acid solution is 0.05%; the ripening rate of the suckling pig corn is 100%, and the starch conversion rate is 75%; the protein content of the soybean meal is 46%; the rice DDGS That is rice distiller's grains, the crude fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com