Sealing mechanism and method for special-shaped tobacco carton bundling and packaging device

A technology for bar cigarettes and sealing, which is used in packaging sealing/fastening, packaging, transportation packaging, etc., can solve the problem of undiscovered sealing mechanism, save packaging time, reduce labor intensity, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

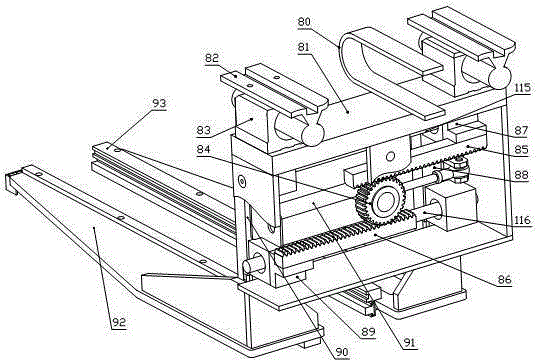

[0023] Example 1. A sealing mechanism for a special-shaped cigarette bundling and packing device, the sealing mechanism 67 is constituted as figure 1 As shown, it includes a sealing longitudinally moving belt 80, which is connected to a clamping mechanism fixing seat 81; a clamping gear 84 is arranged in the clamping mechanism fixing seat 81, and the upper part of the clamping gear 84 is connected to the upper rack 85 connection, the lower part of the clamping gear 84 is connected with the lower rack 86, the upper rack 85 is connected with the first clamping substrate 88 through the first clamping slider 87, and the lower rack 86 is connected with the second clamping slider 89 through the second clamping slider 89. The two clamping substrates 90 are connected, and the second clamping substrate 90 is also connected to the first clamping substrate 88 via the clamping cylinder 91; the first clamping substrate 88 and the second clamping substrate 90 are also respectively provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com