Machine-vision-based online grading and packaging production line for bananas

A packaging line and machine vision technology, applied in the field of banana online grading and packaging line, can solve the problems of inapplicable banana packaging and inapplicable banana packaging, and achieve the effect of saving packaging time and improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

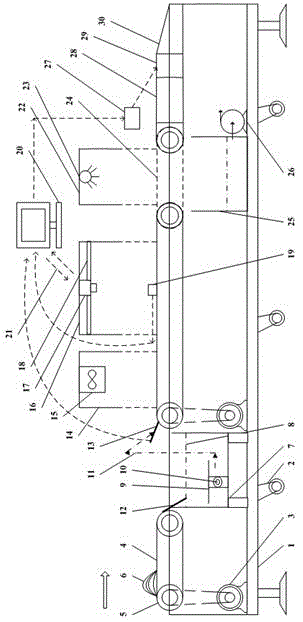

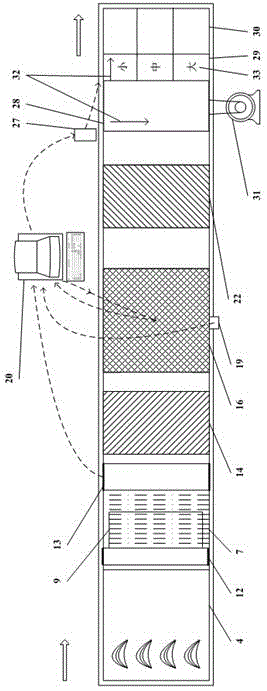

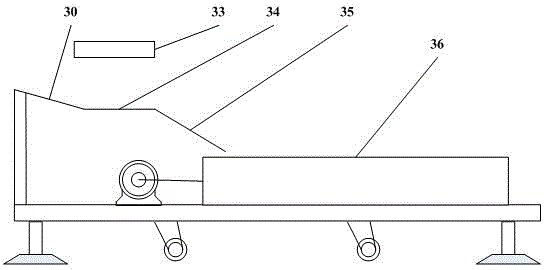

[0021] As shown in Figures 1 to 4, the banana online grading and packaging line based on machine vision of the present invention consists of a transmission device, a grading device, a cleaning and preservation device and packaging equipment.

[0022] As can be seen from FIG. 2 , this specific embodiment takes the banana size index as an example, and divides the size grades into three categories of "small", "medium" and "large" according to the actual situation for explanation. In addition, Fig. 2 expands the width of the production line to about the width of four banana fruit handles for illustration.

[0023] As shown in Figures 1 and 2, the transmission device includes a moving pulley 2, a motor 3, a conveyor belt 4, a sprocket 5, an inclined slideway 12, a conveyor belt 24 with mesh, a longitudinal transmission sorting area 28, a sorting area 29, Fruit unloading chute 30, longitudinal control motor 31, bubble film covering platform 34 and packaging fruit unloading chute 35....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com