Multi-station rotating-type forage compressing and packaging machine

A rotary packaging machine technology, applied in packaging and other directions, can solve the problems of occupying packaging bag space, high production cost, low packaging precision, etc., achieve the effect of occupying small bag space, saving packaging time, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

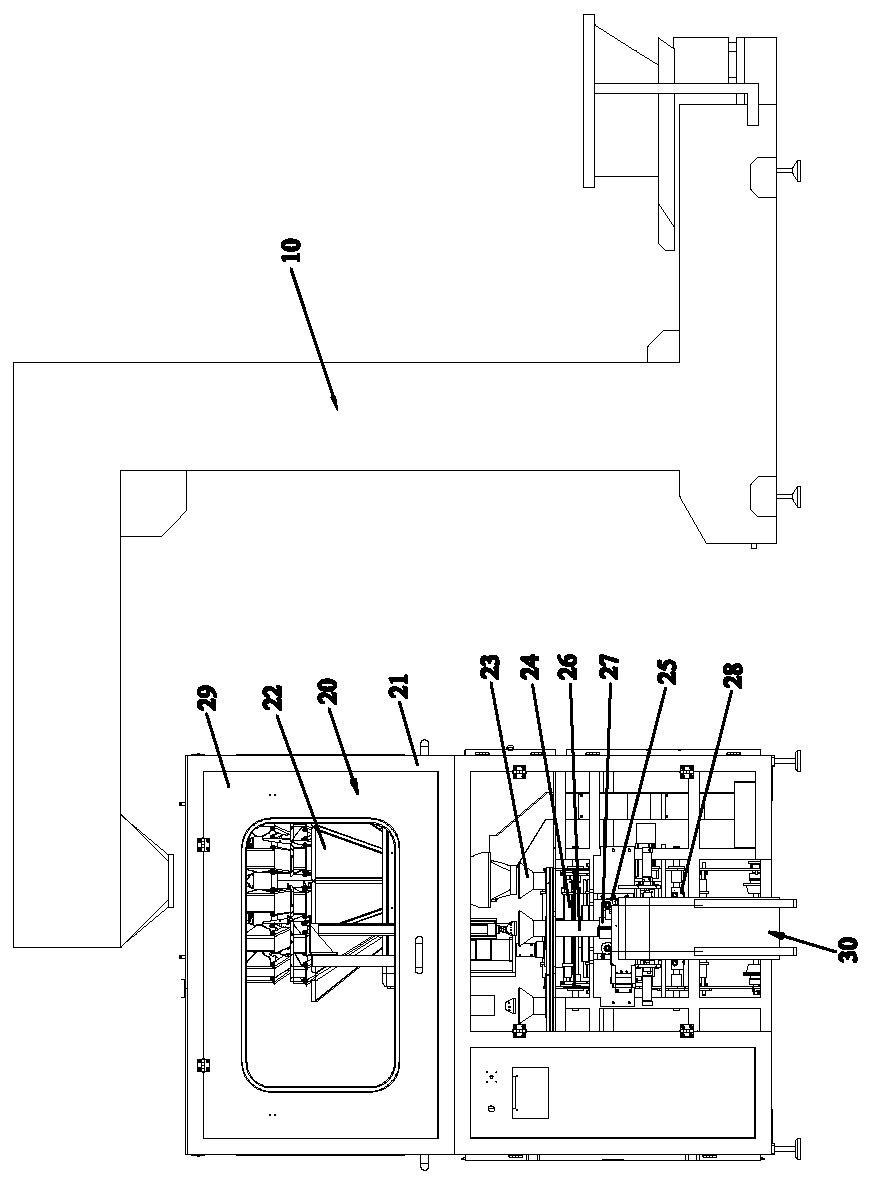

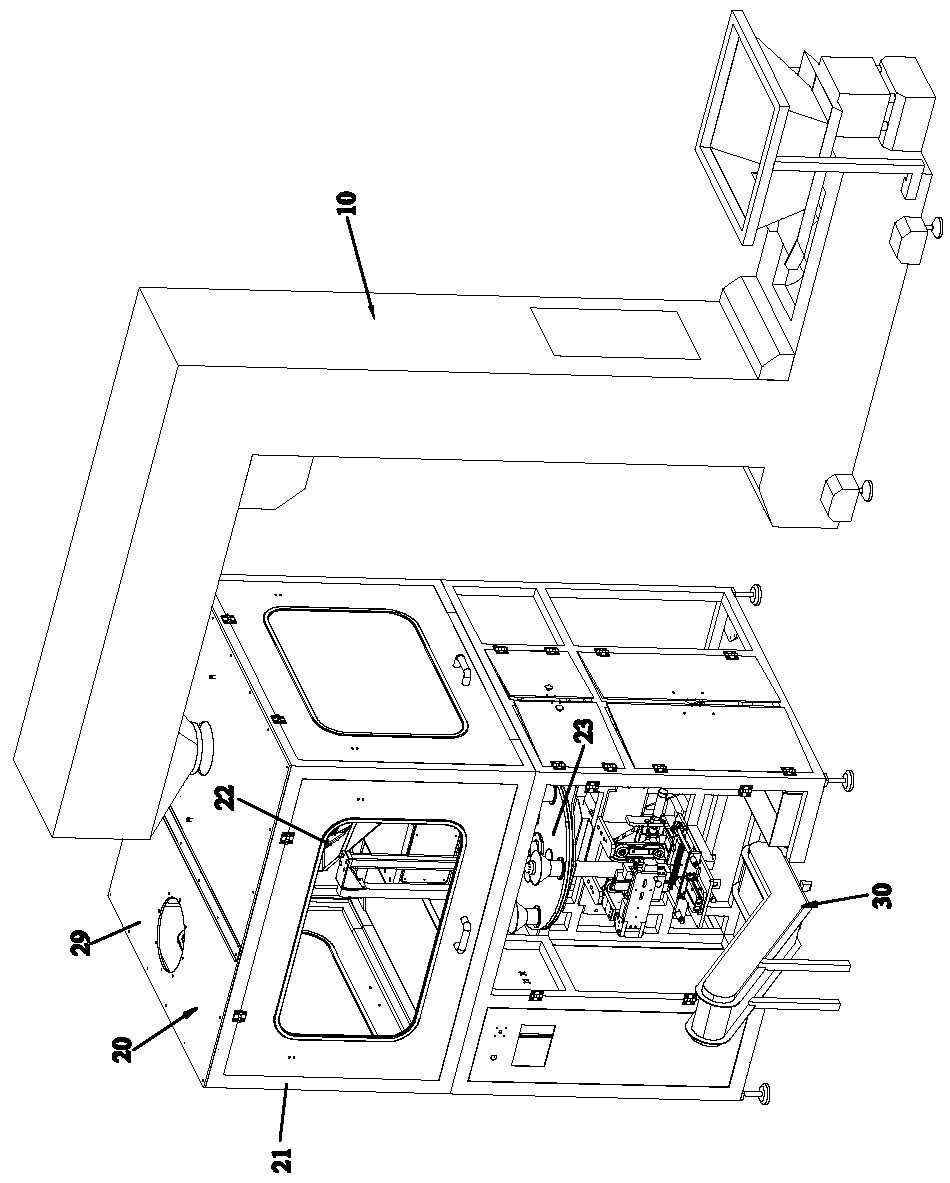

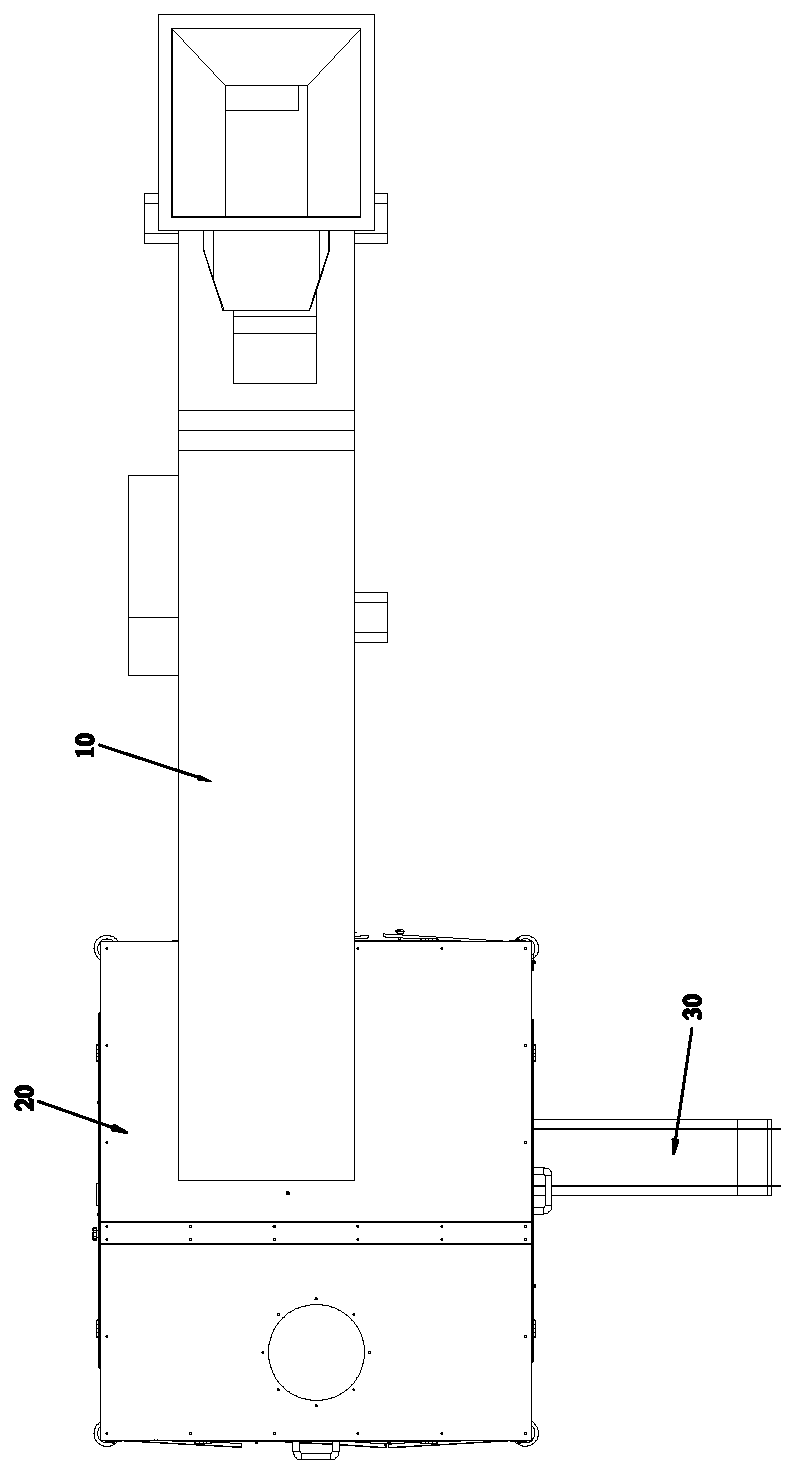

[0033] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of a preferred embodiment of the present invention, including a material elevator 10 , a packaging machine main body 20 and a discharge conveyor 30 .

[0034] The material hoist 10 automatically lifts the material, vibrates and feeds the material.

[0035] The packaging machine main body 20 is arranged on the side of the material hoist 10, and the packaging machine main body 20 includes a frame 21, a weighing mechanism 22, a compression mechanism 23, a film releasing mechanism 24, a film pulling mechanism 25, a bag forming mechanism 26, a longitudinal Sealing mechanism 27 and horizontal sealing mechanism 28; The weighing mechanism 22, compression mechanism 23, film release mechanism 24, film pulling mechanism 25, bag forming mechanism 26, longitudinal sealing mechanism 27 and horizontal sealing mechanism 28 are all arranged in the frame 10 .

[0036] The input port of the weighing mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com