Packaging device and packaging method

A packaging device and packaging method technology, applied in glass molding, glass manufacturing equipment, electrical components, etc., can solve the problems of inconvenient adjustment of pressing force, increase of operation time, and inability to obtain pressing effect, etc., to achieve ample material adaptability , Excellent technical effect, good material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

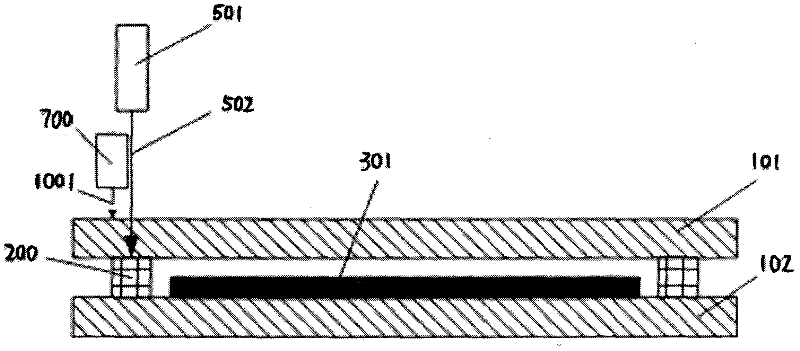

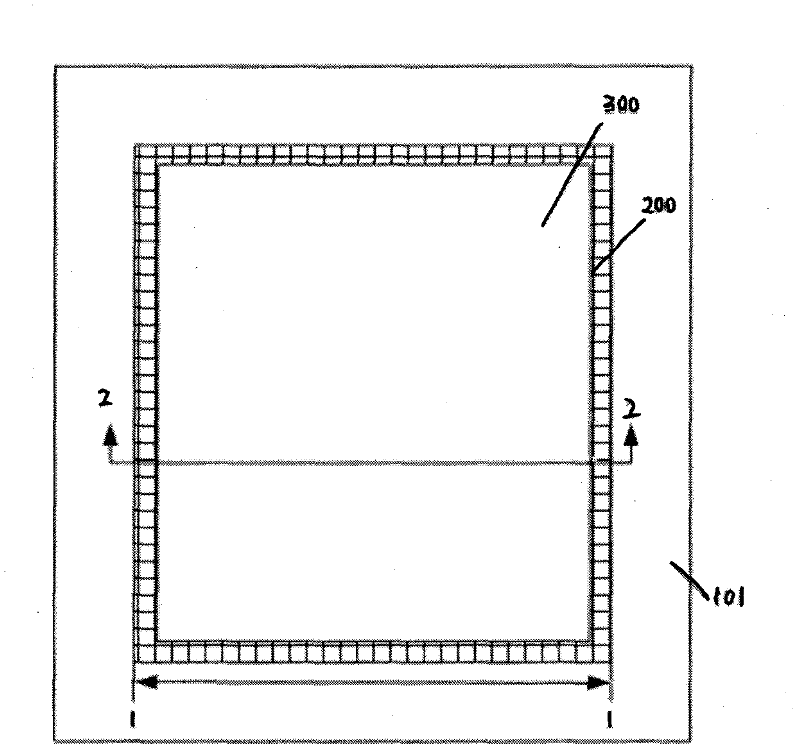

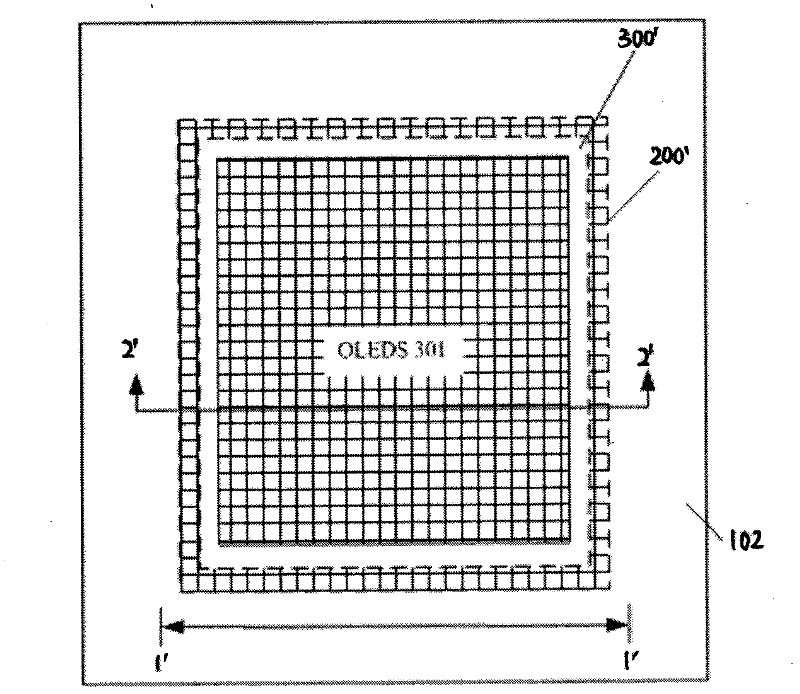

[0037] figure 1 It is a structural schematic diagram of the packaging device involved in the present invention. figure 1 Although not shown in , it should be understood that the sealed glass package to be scanned by a laser or other radiation source is placed on a flat wafer stage and its position can be kept measurable during the packaging process. Such as figure 1 As shown in , a laser or other radiation source system 501 is used to generate a radiation beam 502, which passes through the package cover glass 101 and irradiates on the package line glass frit 200, and the scanning movement of the radiation spot along the package line is formed by relative displacement. However, the jetting fluid jetting assembly 700 of the present invention is independent of the radiation source system 501, and jets the fluid 1001 to the packaging line and ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com