Automatic ton bag packing device suitable for fine powder

A technology for automatic packaging and fine powder materials, which is applied in the directions of packaging, transportation and packaging, and types of packaging items. production, reduce workload, and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

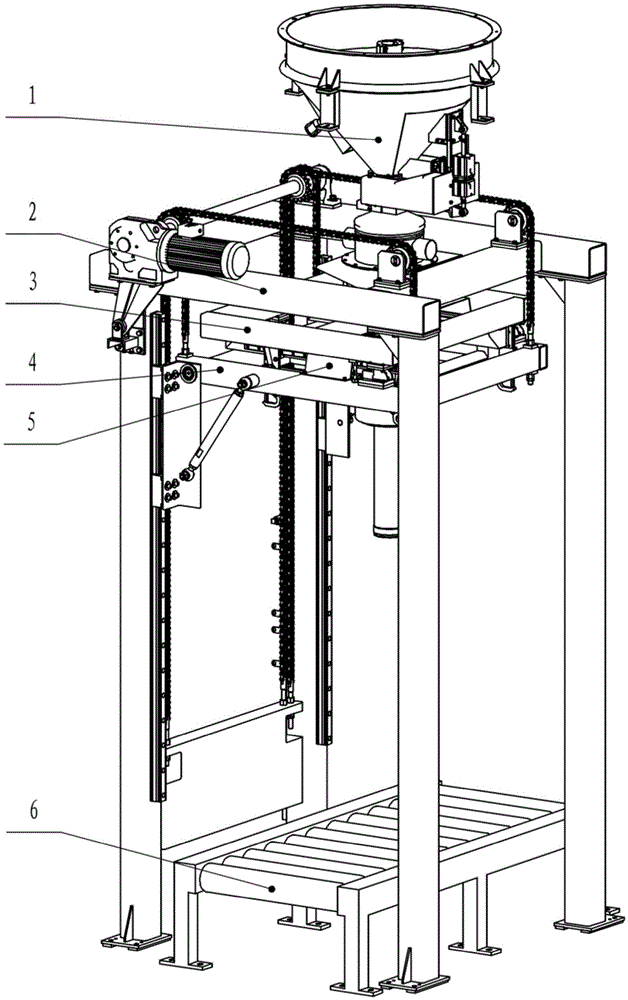

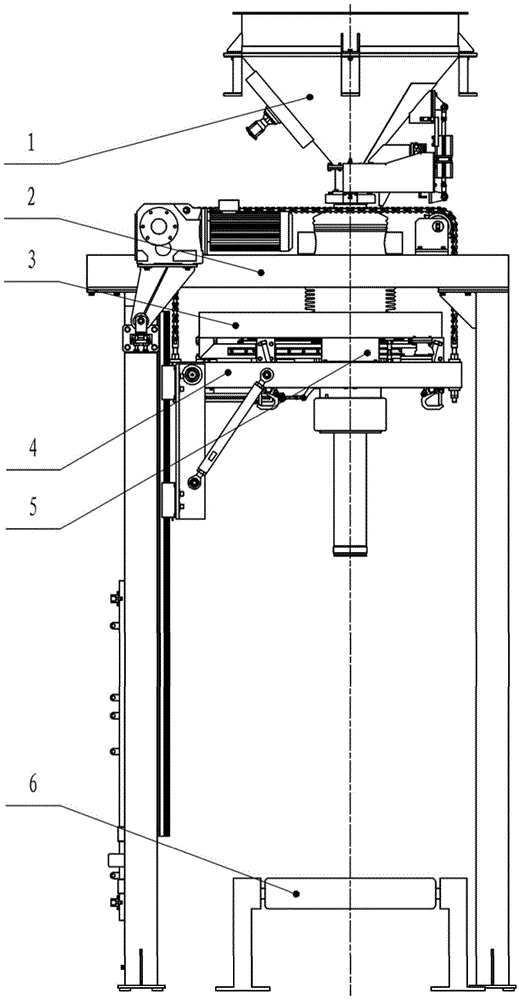

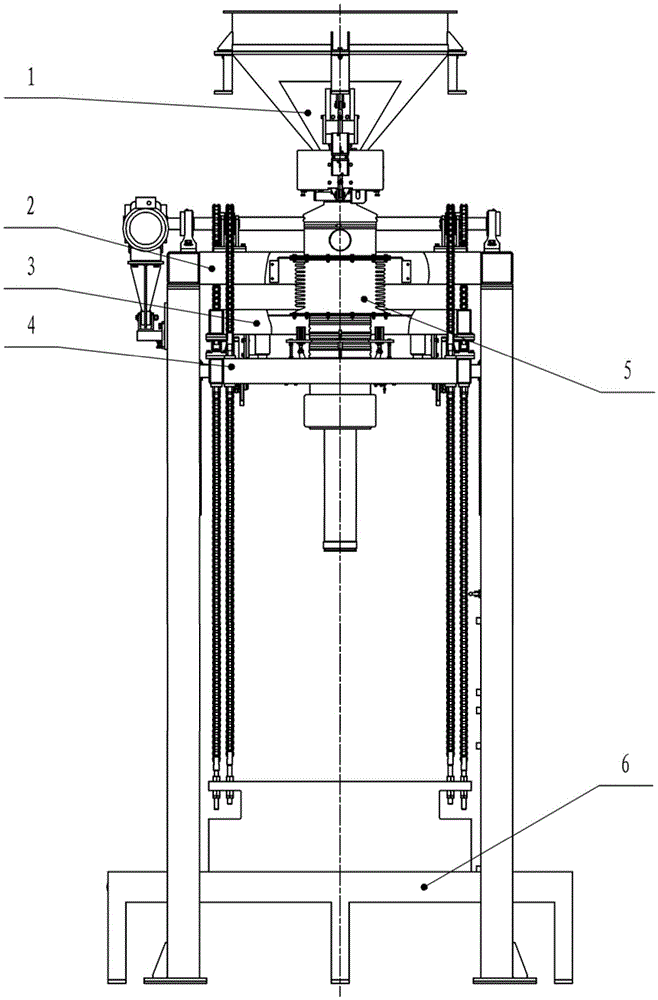

[0035] The specific embodiment of the present invention sees Figure 1 to Figure 24 , an automatic packaging device for ton bags suitable for fine powder materials, which includes a feeder 1, a frame 2, a bag clamping device 3, a lifting frame 4, an inflatable dust removal pipeline 5, and a conveyor 6, wherein the feeder 1 Located in the upper part of the center of the frame 2, the feeder 1 is an outer cylinder lifting vertical screw feeding mechanism. The upper end of the frame 2 is equipped with a chain lifting mechanism driven by a motor. The lifting mechanism drives the lifting frame 4 to move up and down. The lifting frame 4 includes Lifting frame 41, the upper end of lifting frame 41 is provided with three weighing sensors 42, is connected with bag clamping device 3 on the weighing sensor 42, and the bottom of bag clamping device 3 is provided with the bag hanging mechanism 32 that can translate and bag opening mechanism 33, The top of the bag clamping device 3 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com