Method and device for reinforcing underwater welding seam based on laser impact wave technology

A technology of shock waves and laser pulses, which is applied in strengthening treatment of corrosion-resistant welds, strengthening underwater welds, and high-strength areas of deep-sea components. control, pressure is precisely controlled, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific details and working conditions of the method proposed by the present invention will be described in detail below in conjunction with accompanying drawings

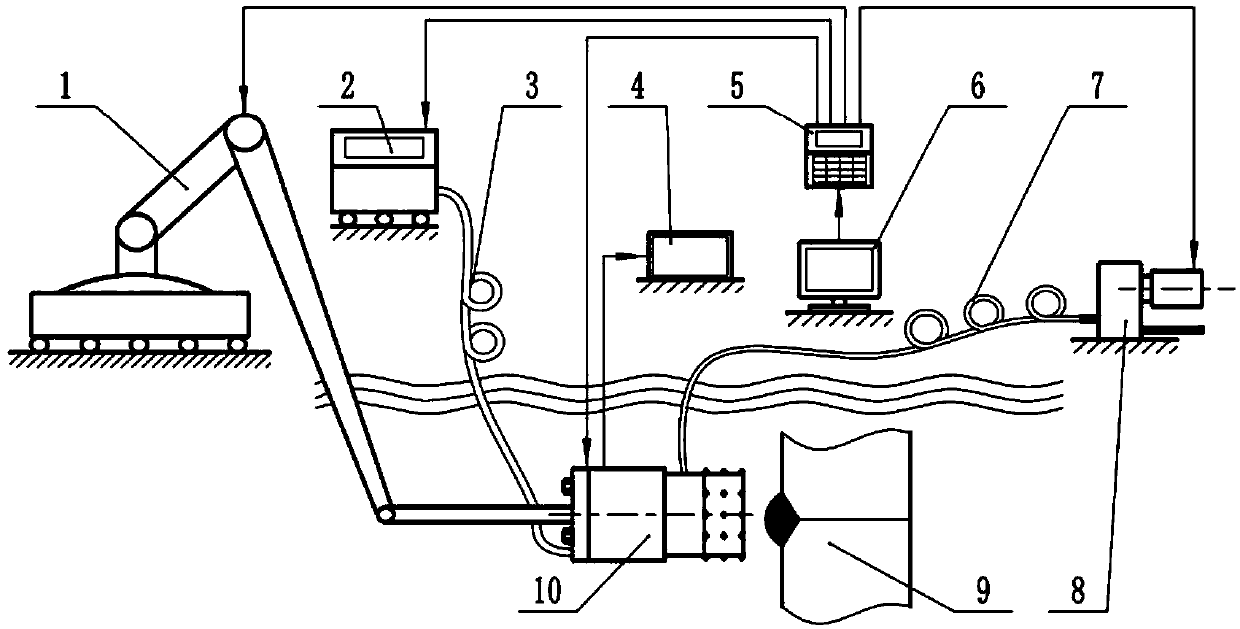

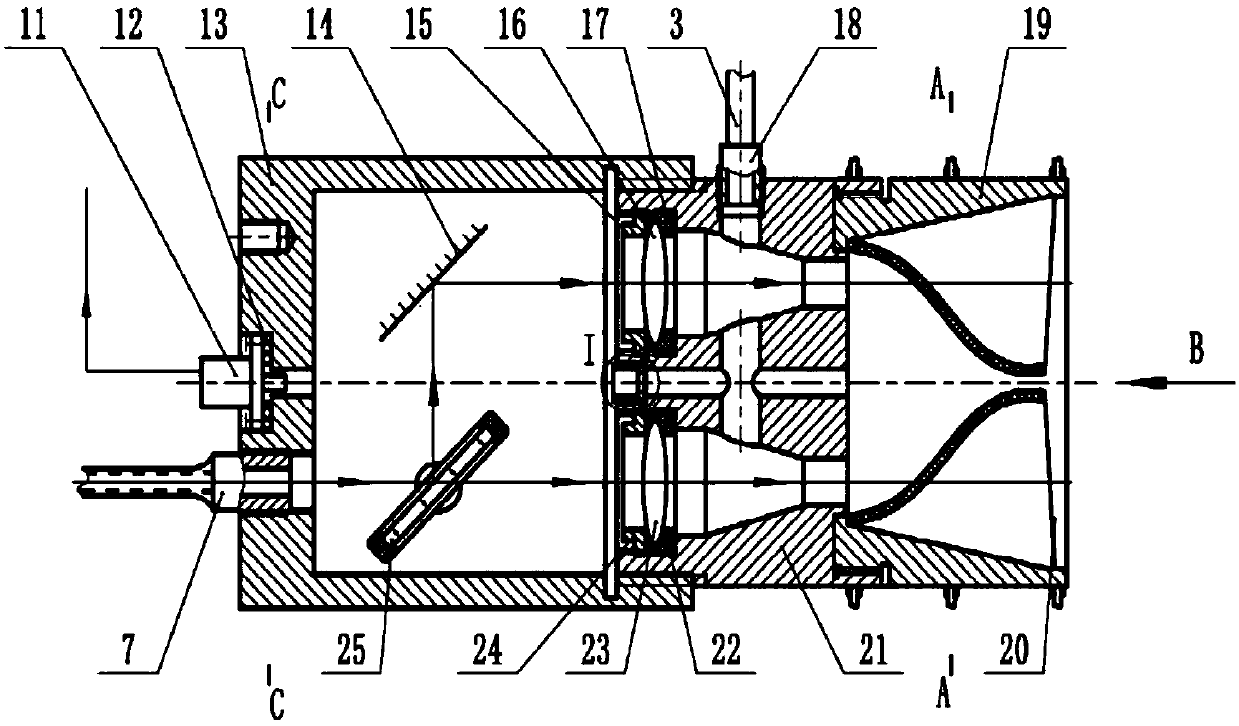

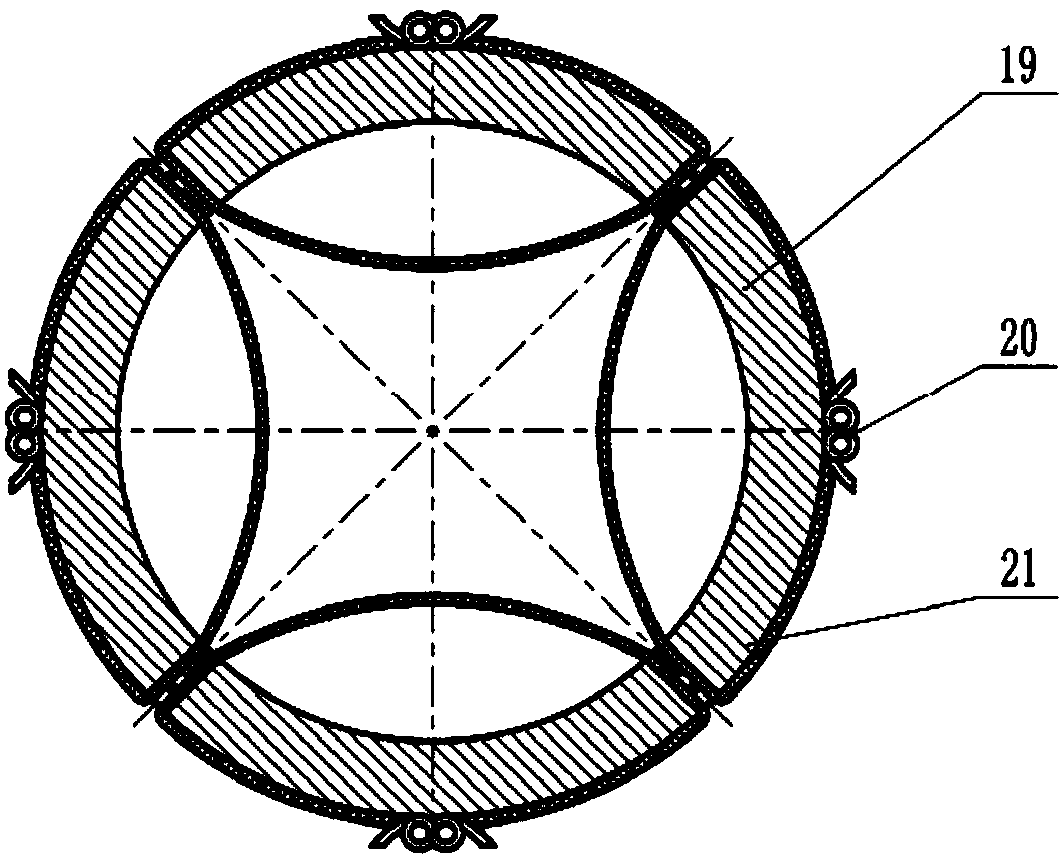

[0031] The device of the present invention includes a laser generator 2, a light guide system, a distance adjustment system, a water supply system and a control system. The light guide system includes a light guide fiber 3, a reinforced impact head 10, a spectroscopic chamber housing 13, a total reflection mirror 14, a first blank holder 15, a first converging lens 16, a first soft gasket 17, a hybrid 21, The second soft spacer 22, the second converging lens 23, the second bezel 24, the beam splitter 25, the third bezel 26, the third soft spacer 27, the transparent glass sheet 28, the inner tapered hole sleeve 19 and anti-recoil valve 20. Both ends of the optical fiber 3 have their own optical connectors, one end of which is connected to the laser generator 2, and the other end is connected to the stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com