Workpiece tray exchange device of vertical type lathe exchange workbench

A vertical lathe and pallet exchange technology, which is applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve problems such as wasting time, achieve the effect of improving processing efficiency and shortening auxiliary processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

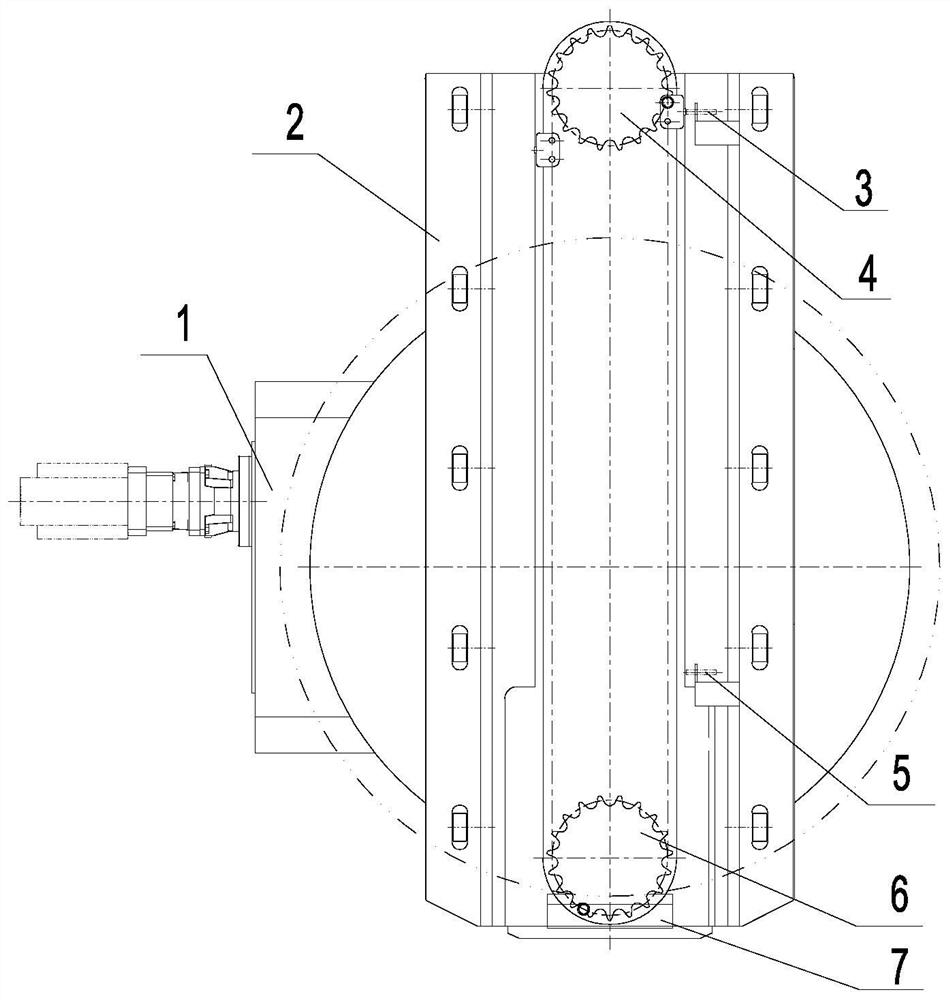

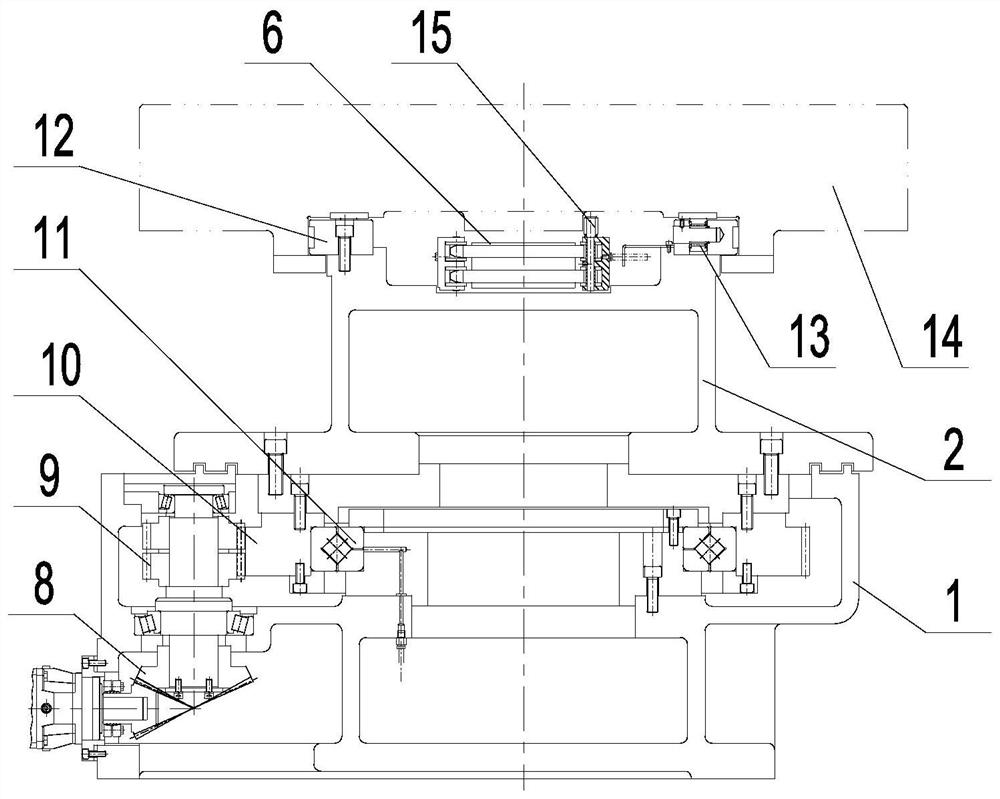

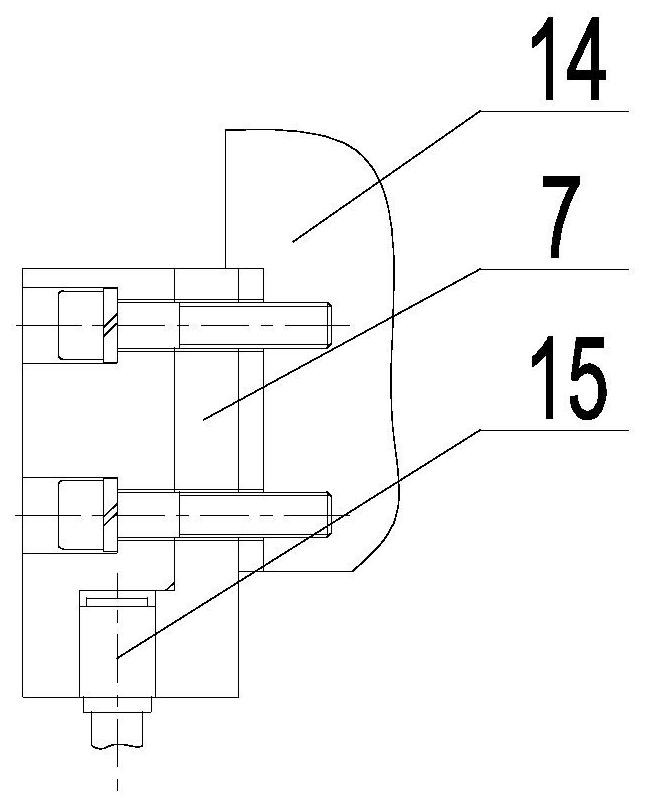

[0015] Depend on figure 1 , figure 2 As shown, a workpiece pallet exchange device for a vertical lathe exchange workbench includes a base 1, the base 1 is driven by a servo motor, the output shaft of the servo motor is connected to a reducer, and a bevel gear is fixed on the output shaft of the reducer. The bevel gear is connected to the anti-backlash pinion 9 through the spiral bevel gear 8. The anti-backlash pinion 9 is two coaxial gears, and a gasket with adjustable thickness is arranged between the two gears. The gears 10 are meshed, and the large gear 10 is connected with the revolving base 2 . By adjusting the thickness of the gasket between the anti-backlash pinion gears 9, the gap between the pinion gear and the bull gear can be adjusted, so that the revolving base 2 has a small gap during the revolving process. The top of the base 1 is connected to the revolvin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com