Overhang roll overturning vertical demolding pipe manufacturing equipment

A suspension roller and equipment technology, applied in the field of pipe making equipment, can solve the problems of increased manufacturing cost, low production efficiency, poor impermeability and external pressure load, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

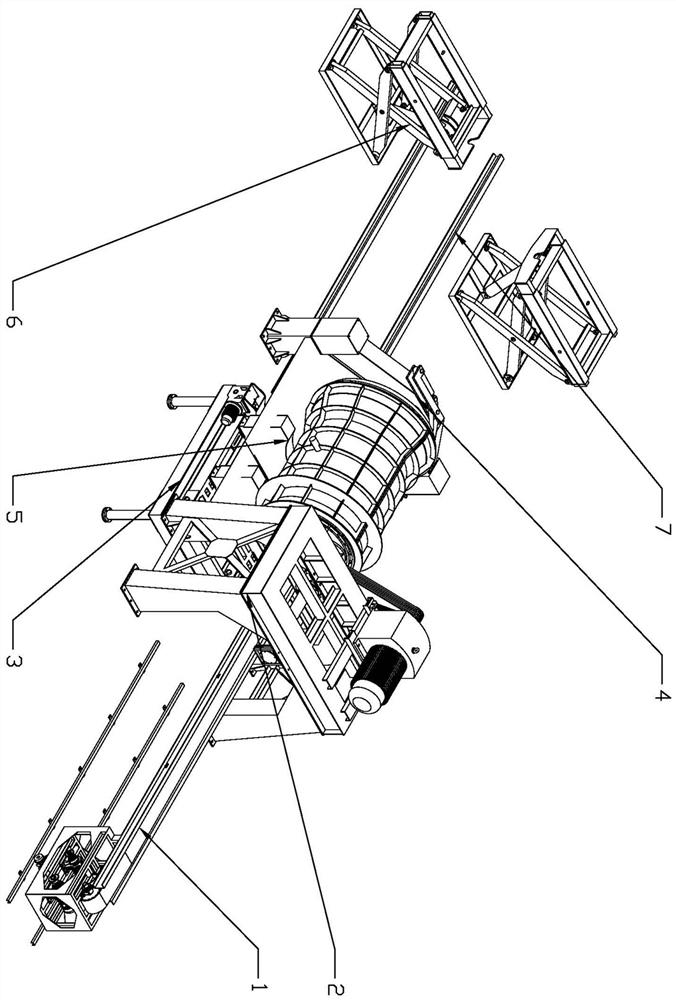

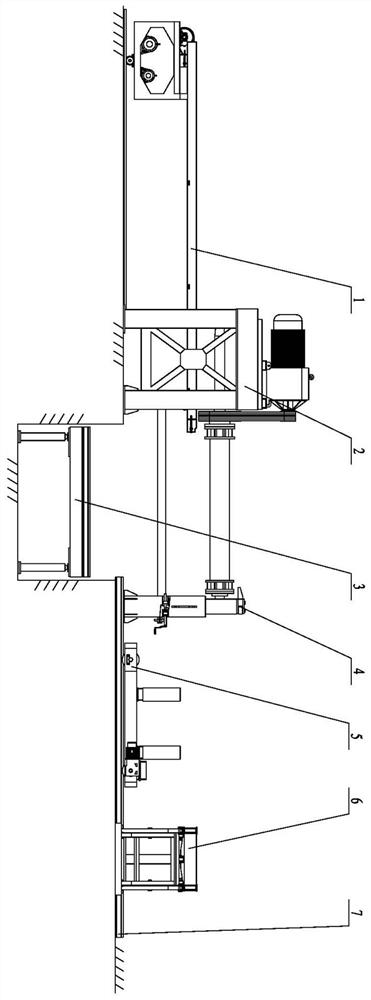

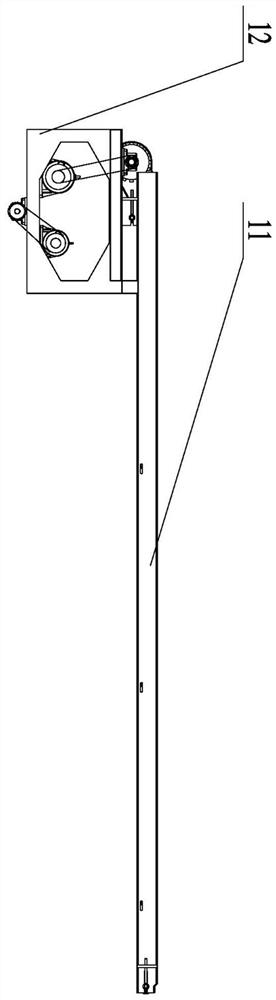

[0035] like Figure 1-12 As shown, in order to achieve the above-mentioned purpose, the present invention provides a kind of suspension roller turning and vertical stripping pipe making equipment, including the equipment body, the equipment body is directly fixed and installed on the ground, and the ground where the equipment is installed is also equipped with pits for The lifting platform 3 is installed, and the equipment body includes a feeder 1 in turn, a hanging roller machine 2 used in conjunction with the feeding machine 1, a lifting platform 3 arranged in cooperation with the hanging roller machine 2 and installed in the pit, and the hanging roller machine 2 A positioning fork 4 is arranged at the exit of the fork, and a ground guide rail 7 is installed on the ground at the rear end of the positioning fork 4, and a transport trolley 5 is correspondingly arranged on the ground guide rail 7, and a lifting and turning machine 6 is installed on both sides of the ground guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com