Core-lifting rotary type vibrating extrusion forming tubing machine

A rotary, molding technology, applied in ceramic molding machines, manufacturing tools, supply devices, etc., can solve the problems of cracks, high manufacturing costs, and high labor costs, and achieve the effect of improving work efficiency and reducing auxiliary process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

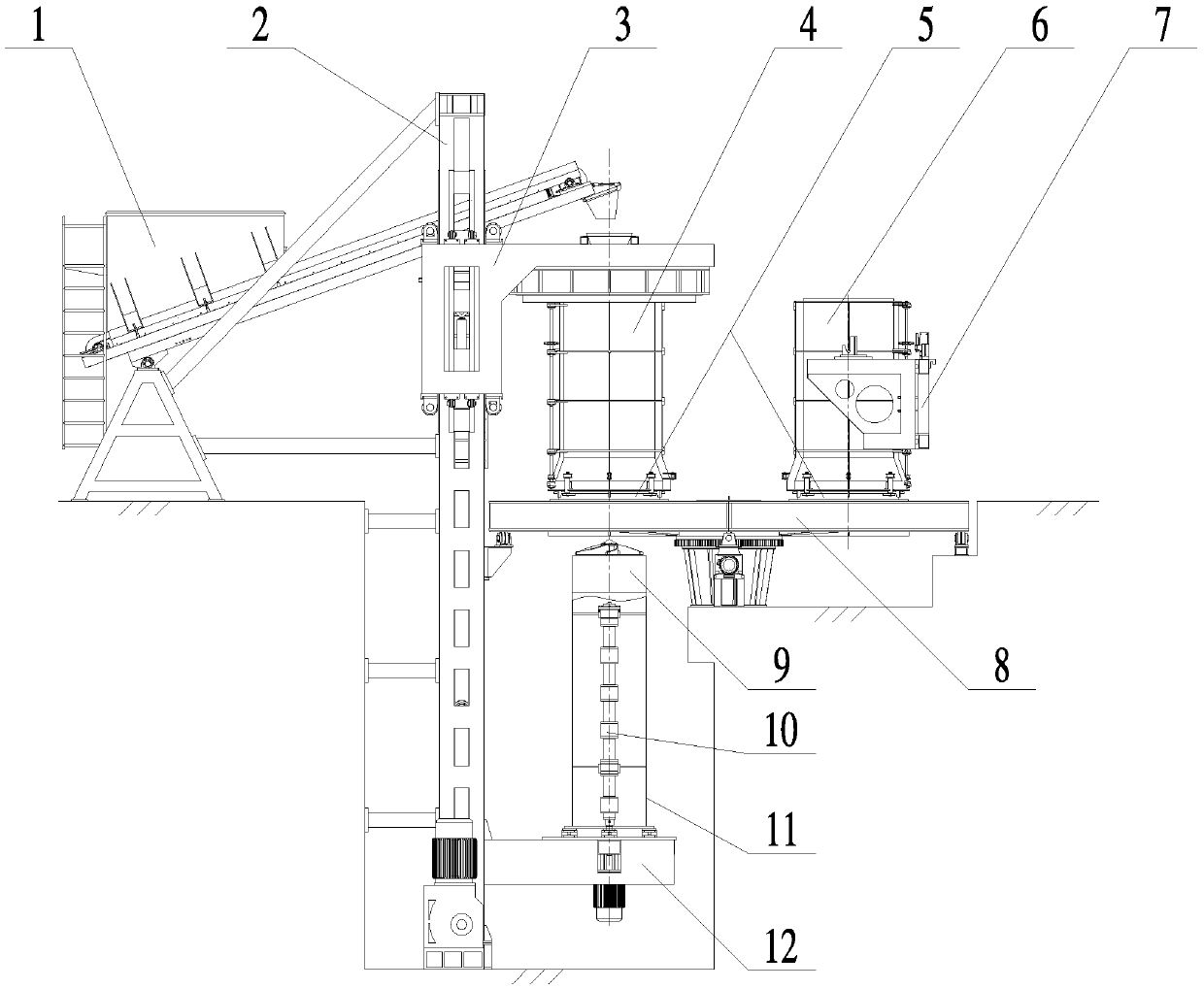

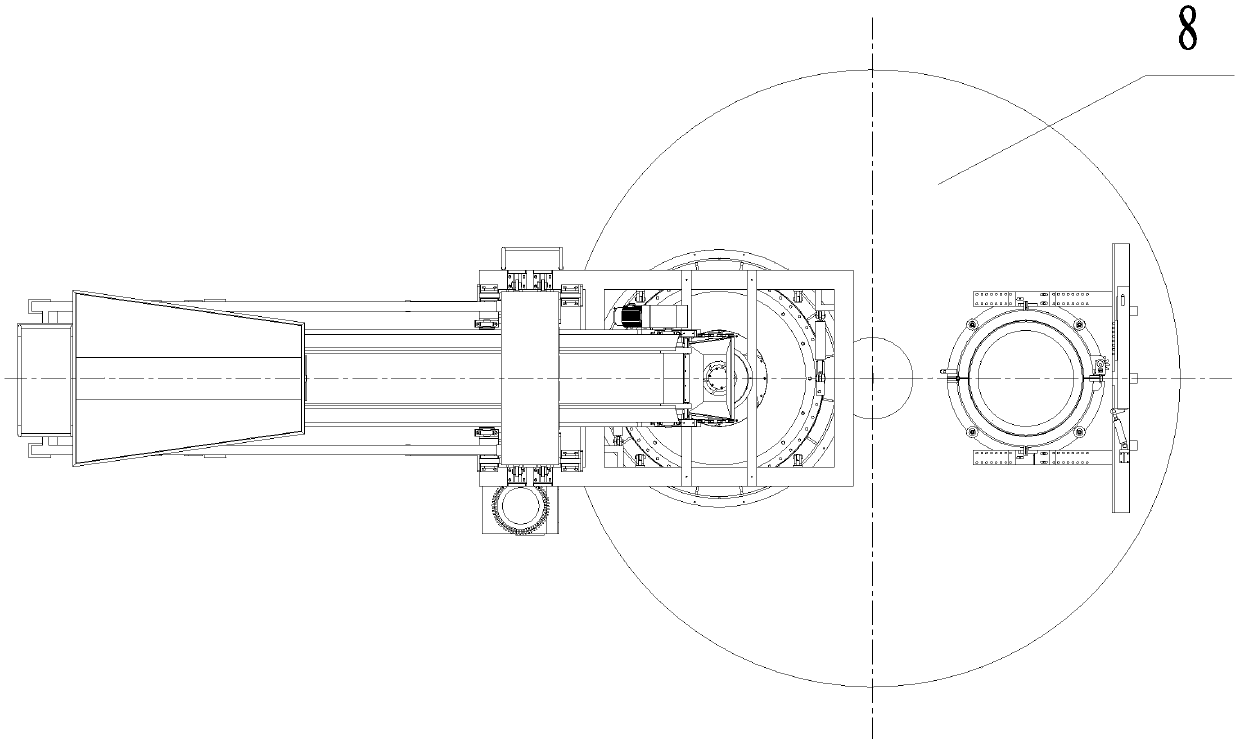

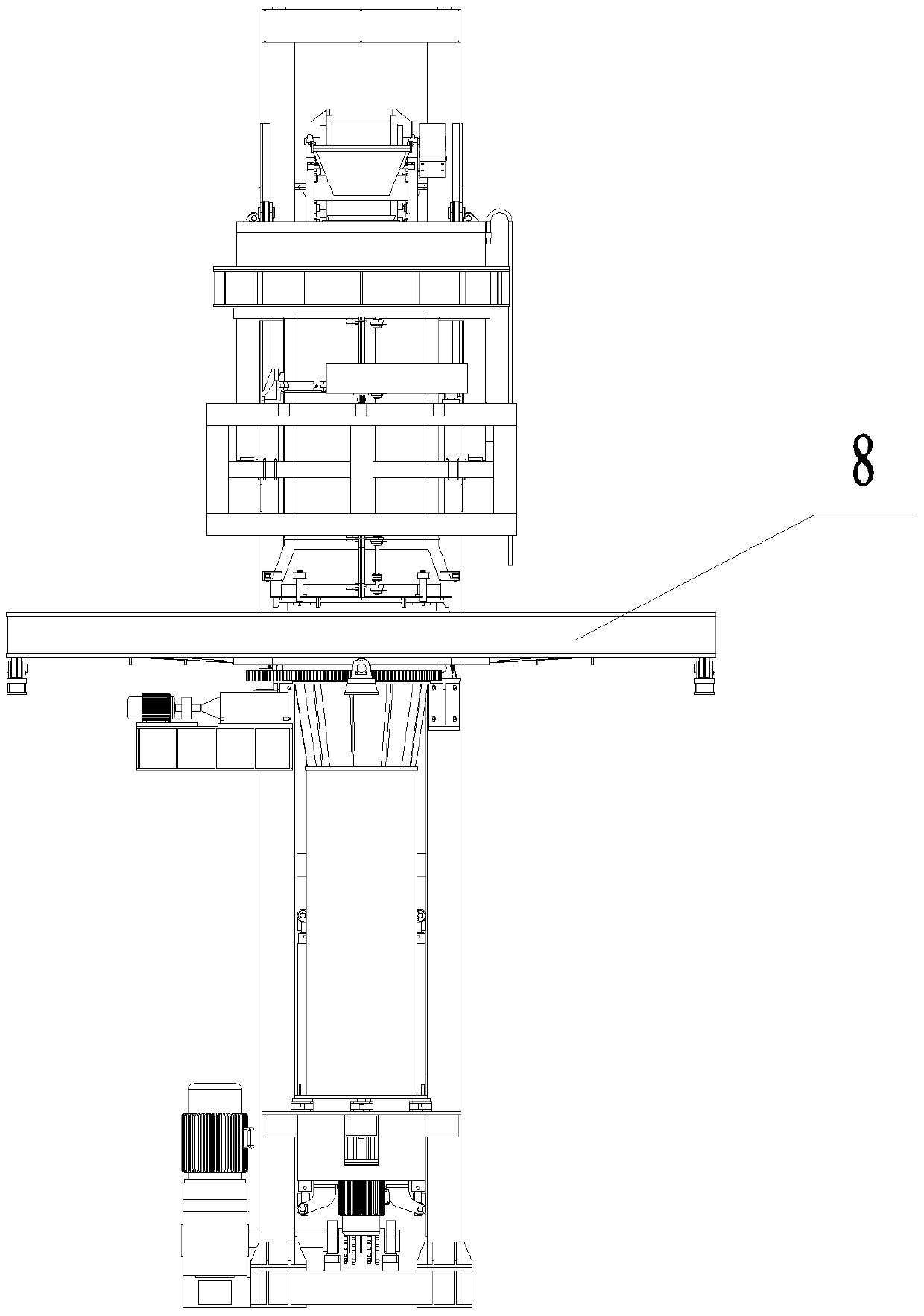

[0058] The present invention as Figure 1-26 As shown, it includes frame 2, feeding mechanism 1, rolling plate 3, rotating platform 8, several outer molds (such as setting outer mold A5 and outer mold B6), rotating uniform material mechanism 9, vibrating mandrel 10 and inner mold 11 ;

[0059] A plurality of outer molds are arranged on the rotating platform 8, and the rotating platform drives the outer molds to rotate. The rotating platform is located above the inner mold. The rotating platform can be driven by a motor to rotate during work, and rollers are set around the platform. , to improve the reliability of rotation;

[0060] The rotating uniform material mechanism is arranged on the top of the inner mold, the vibrating mandrel is arranged in the inner mold, the inner mold moves up and down relative to the frame through the lifting mechanism 12, and the inner mold enters the outer mold to form a lumen;

[0061] The feeding mechanism is used to feed the tube cavity, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com