Drilling jig for machining connecting gusset of rotating frame of annular cooler and using method

A technology for connecting angle plates and revolving frames, applied in the direction of drilling dies for workpieces, etc., can solve the problems of unreliable guarantee of manufacturing accuracy, low production efficiency, etc., to shorten the time of a large number of auxiliary processes, accurate and reliable positioning, and improve production operations. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

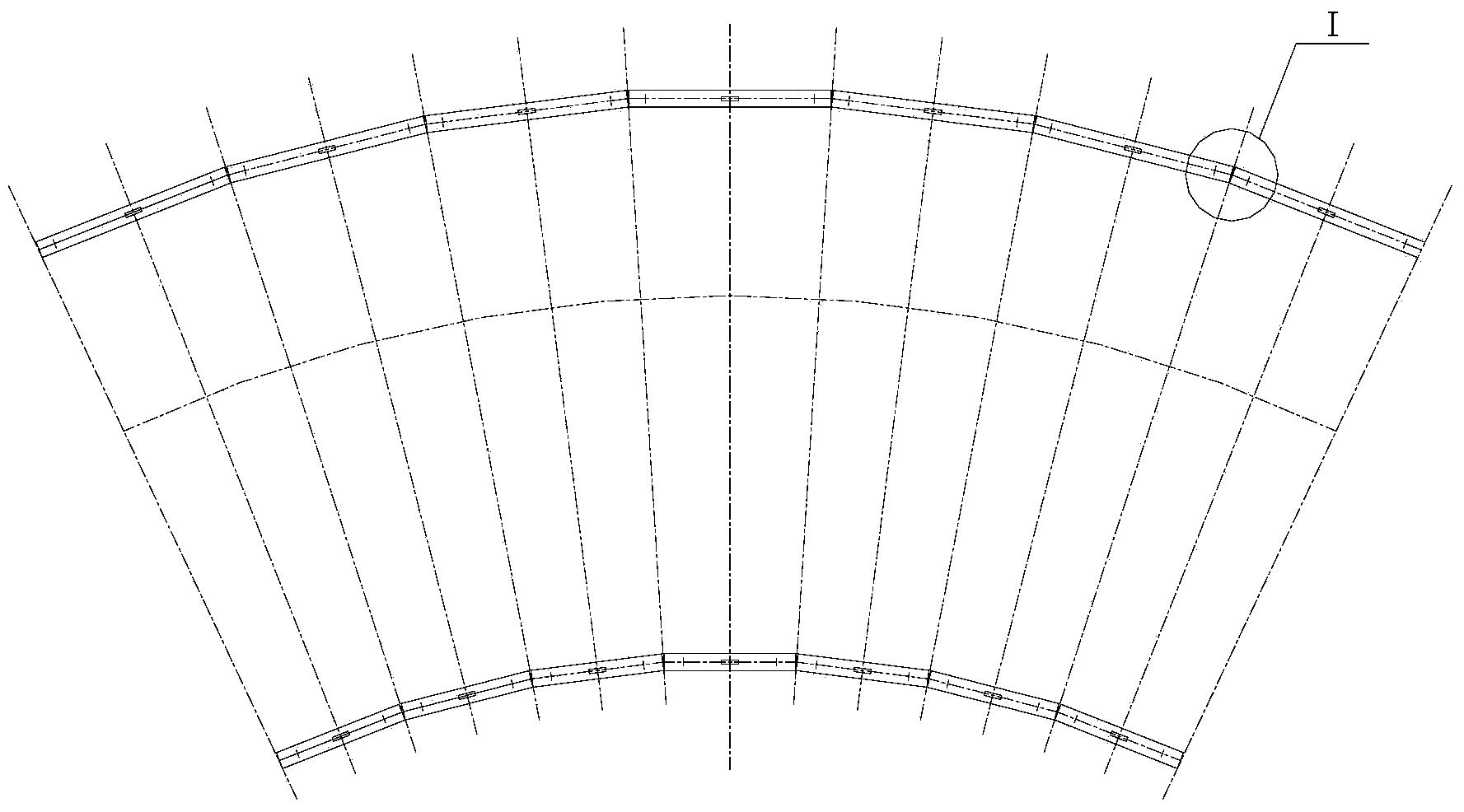

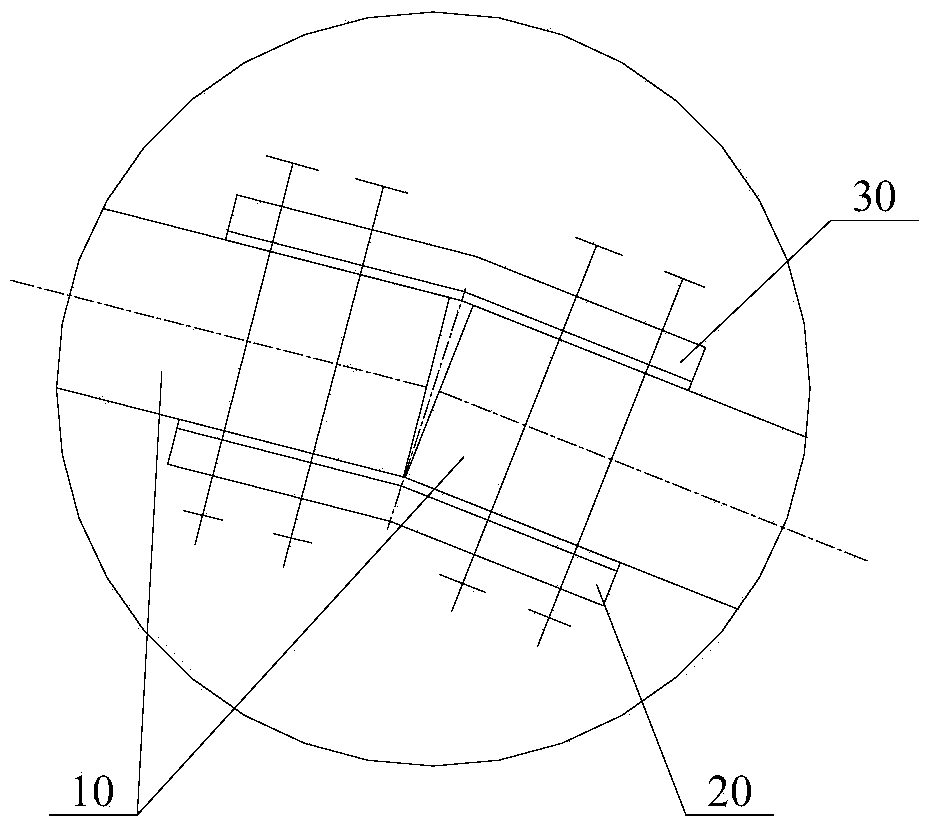

[0043] See Figure 7 with Figure 8 ,in, Figure 7 It is the front view of the drilling jig used to process the connecting angle plate of the rotary frame of the annular cooler described in this embodiment, Figure 8 for Figure 7 top view.

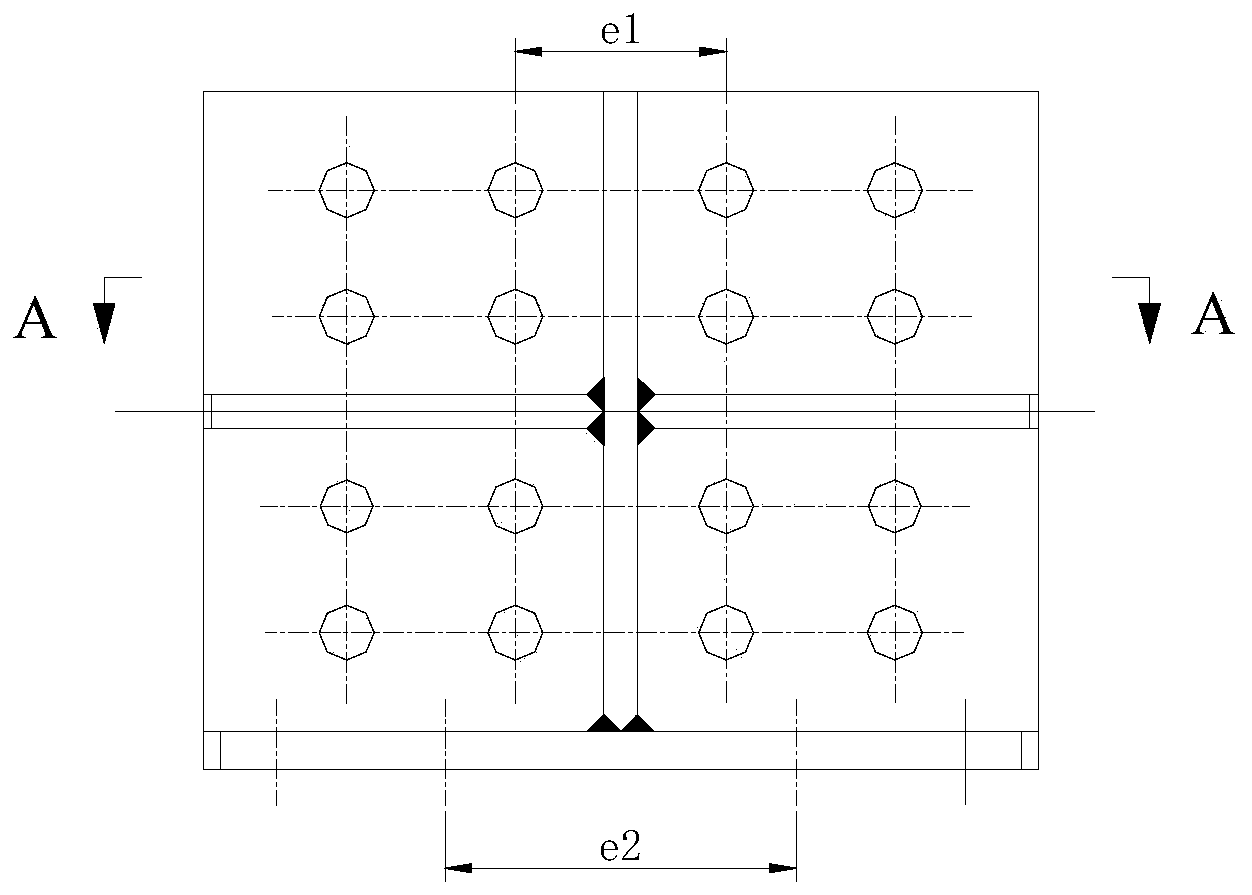

[0044] Based on the feature that the hole spacings L1, L2, L3 and L4 of the connecting holes on the connecting angle plate of the rotary frame of the annular cooler adopt standard design, the present invention provides a corresponding drilling mold. As shown in the figure, the drill template includes two hinged drill template bodies 1, the relative positional relationship between the two drill template bodies can be adjusted, and each drill template body 1 is respectively provided with a working hole connected to the gusset to be processed. Correspondingly, there are a plurality of die holes 11, 12, and the same side of the two drill die bodies 1 is used to bear against the connecting angle plate to be processed, so as to complete the...

Embodiment 2

[0054] This embodiment is the same as the first embodiment in terms of basic composition and connection relationship, the difference lies in that the adjustment mechanism 2 with a different structure is adopted. See Figure 12 , which is a top view of the drilling jig used to process the connecting angle plate of the rotary frame of the annular cooler described in this embodiment. In order to clearly show the difference and connection between this solution and the first embodiment, the same functional components are designated with the same marks generation.

[0055] In this solution, the adjustment mechanism 2 also includes two fixing frames 21, which are respectively arranged on the two drilling template bodies 1, and the two bolts 24 respectively form a threaded matching pair with one of the two fixing frames 21, and each The rod ends of the bolts 24 respectively abut against the other of the two fixing frames 21 to adjust the working angle between the two drilling templat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com