Two-spindle numerically-controlled machine tool with translation interaction worktables

A technology of CNC machine tools and workbenches, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of not being able to maximize production efficiency, occupying more auxiliary processing time, occupying processing time, etc. The effect of shortening auxiliary processing time, preventing cutting fluid splash, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

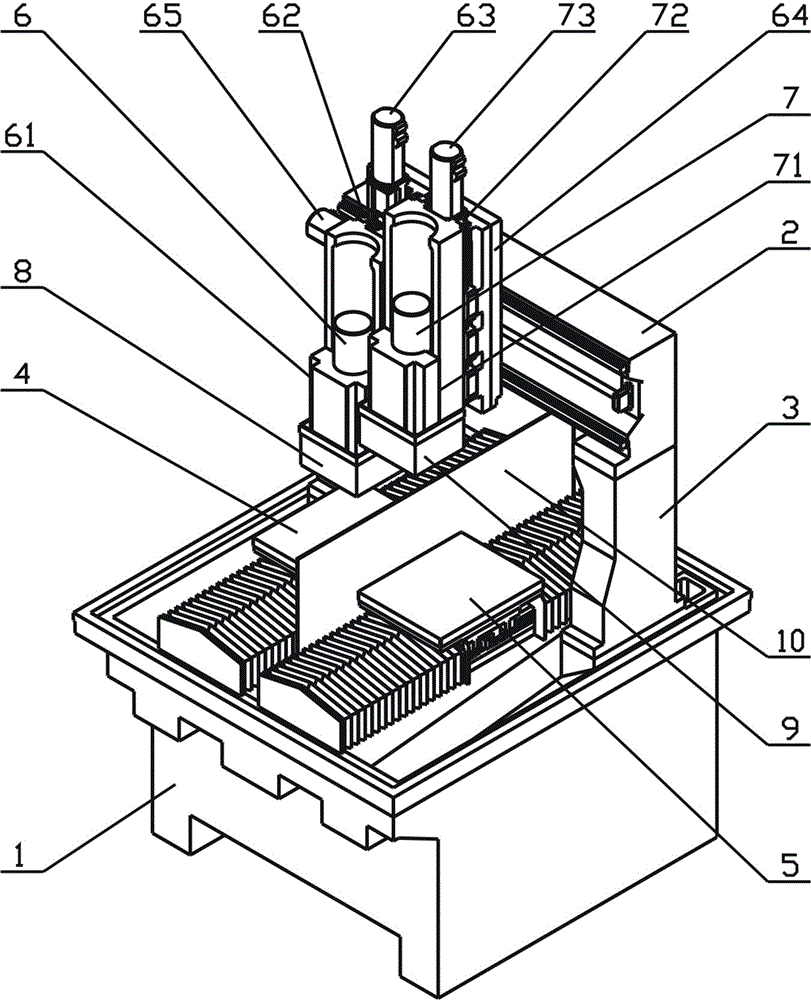

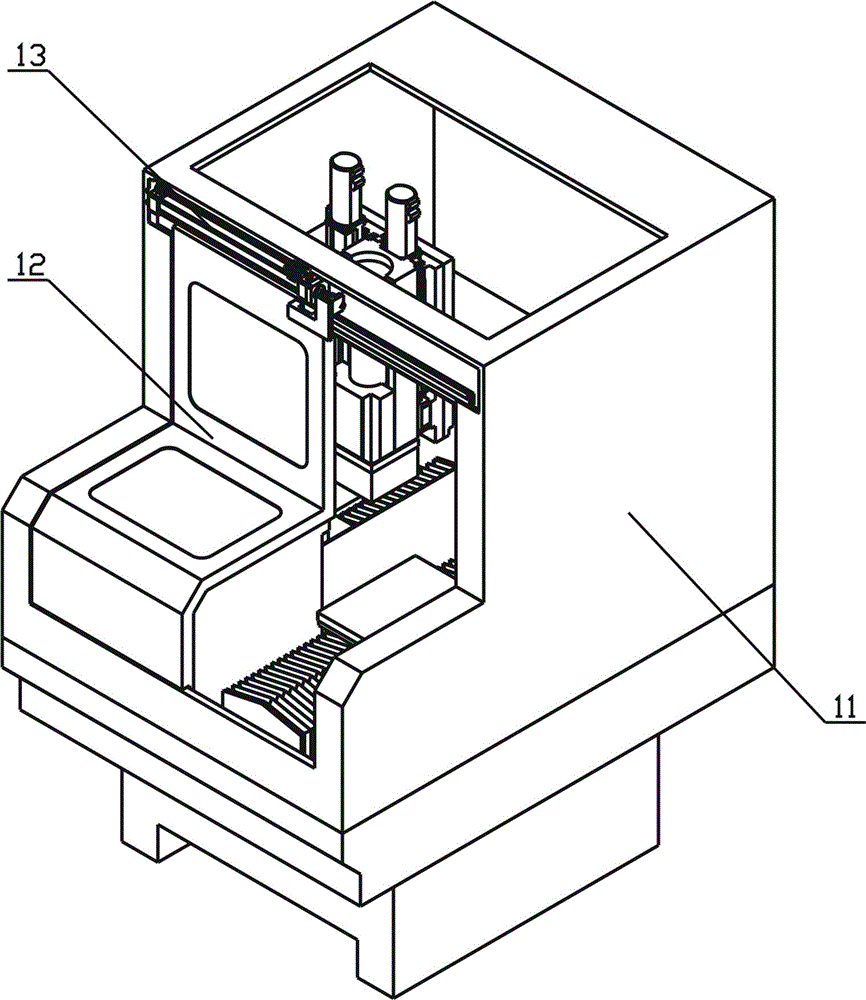

[0017] combine figure 1 and figure 2 As shown, a dual-spindle CNC machine tool with a translational interactive workbench of the present invention has a bed 1, a beam 2, a column 3, a first workbench 4, a second workbench 5, a first electric spindle 6, and a second electric spindle. Main shaft 7, water retaining curtain 8, water retaining curtain 9, isolation plate 10, protective cover 11 and automatic protection door 12 form. The beam 2 and two columns 3 form a gantry structure and are installed on the bed 1; the first workbench 4 and the second workbench 5 arranged in parallel are respectively installed on the bed 1 through guide rail slider devices, and are controlled by servo motors and balls. The two Y-axis servo drive devices composed of lead screws are controlled separately, and the horizontal and vertical feed motions are made along the Y-axis. The first electric spindle 6 is clamped in the spindle clamping body 61, and the second electric spindle 7 is clamped in th...

Embodiment 2

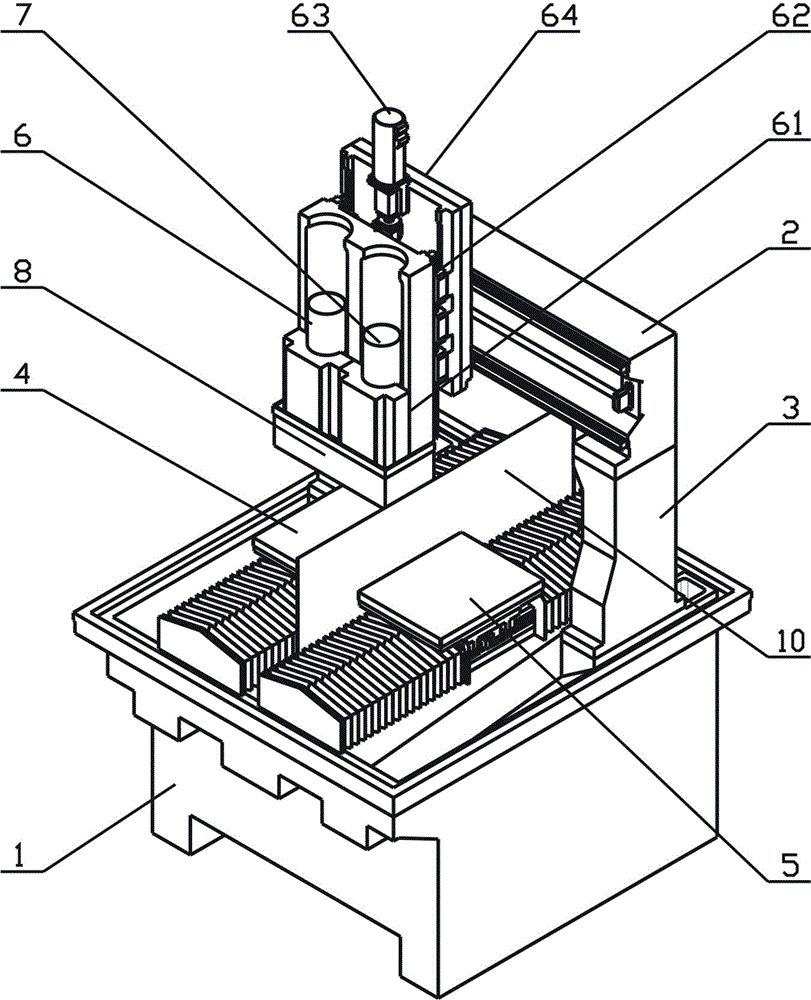

[0020] combine image 3 and Figure 4 As shown, a dual-spindle CNC machine tool with a translational interactive workbench of the present invention has a bed 1, a beam 2, a column 3, a first workbench 4, a second workbench 5, a first electric spindle 6, and a second electric spindle. The main shaft 7, the water retaining curtain 8, the isolation plate 10, the protective cover 11 and the automatic protective door 12 are formed. The beam 2 and two columns 3 form a gantry structure and are installed on the bed 1; the first workbench 4 and the second workbench 5 arranged in parallel are respectively installed on the bed 1 through guide rail slider devices, and are controlled by servo motors and balls. The two Y-axis servo drive devices composed of lead screws are controlled separately, and the horizontal and vertical feed motions are made along the Y-axis. The first electric spindle 6 and the second electric spindle 7 are clamped side by side in the spindle clamping body 61. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com