Oil pump shell machining method

A technology of an oil pump housing and a processing method, which is applied in the field of cutting processing technology, can solve problems such as affecting the processing accuracy and processing quality of parts, greatly affecting the processing accuracy and processing quality, and irregular shape of workpieces, so as to improve production or manufacturing efficiency. , The effect of stable and reliable clamping and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

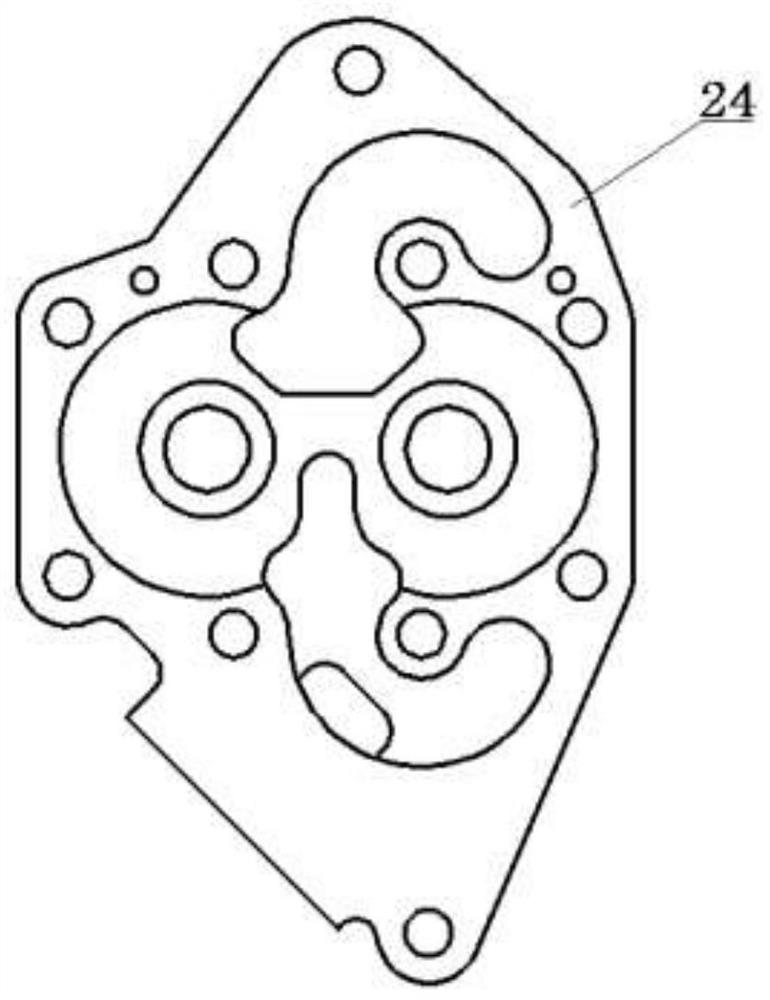

[0031] Such as Figure 1 to Figure 8 As shown, the present invention provides a method for processing an oil pump casing, comprising the following steps:

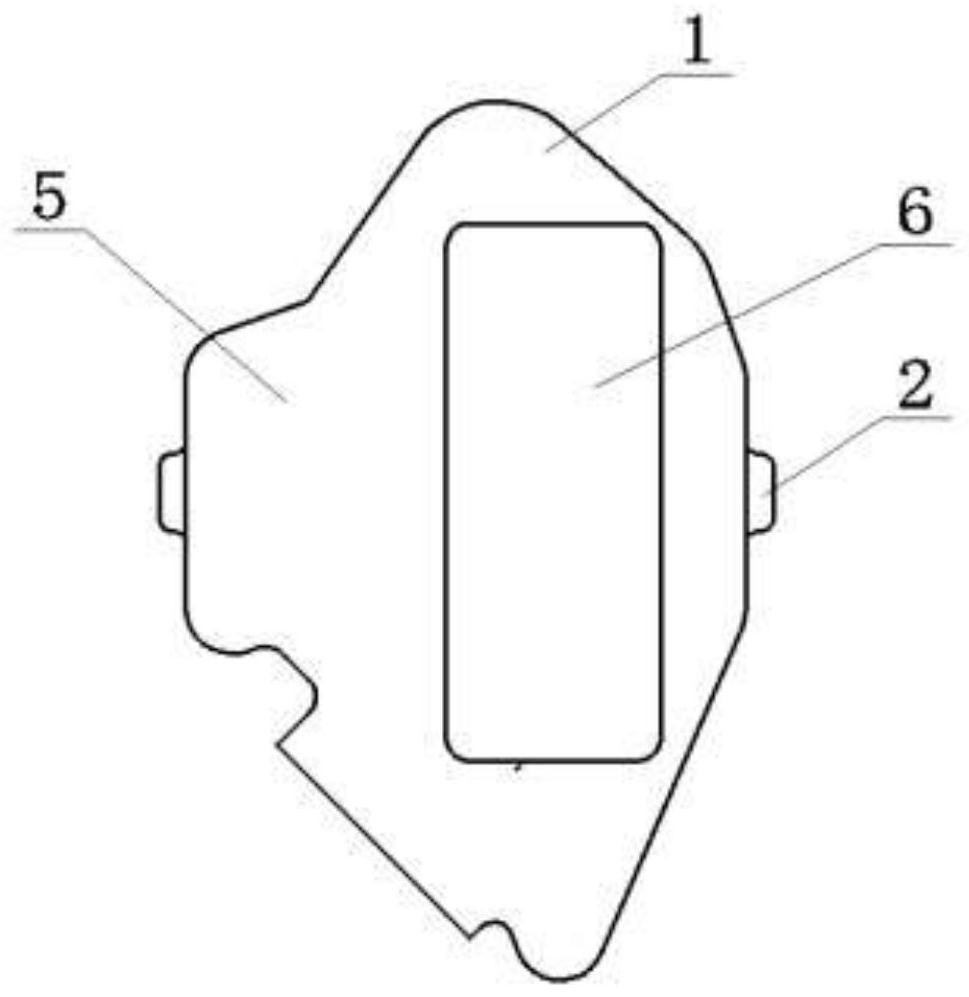

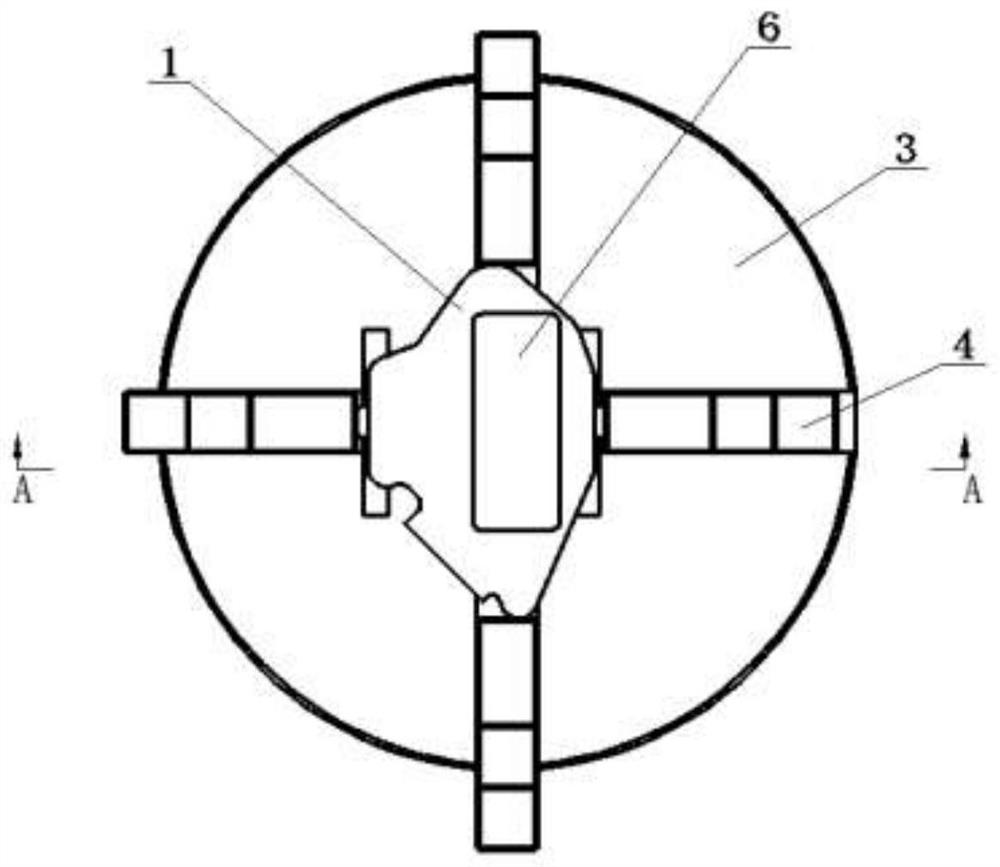

[0032] Step 1: According to the shape of the pattern in the pre-drawn design drawings, the blank 1 is produced by casting technology, and at least a pair of process convex towers 2 are evenly arranged around the blank 1;

[0033] Step 2: Provide machine tools;

[0034] Step 3: Provide a chuck 3, install the chuck 3 on the machine tool table, at least two pairs of claws 4 are installed on the chuck 3, and clamp at least one pair of process convex towers 2 between the pair of claws 4 The blank 1 in the step 1 is clamped on the chuck 3, the outer surface of the blank 1 is milled by the machine tool to obtain the datum plane 5, and then a datum hole 6 is milled in the datum plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com