Manufacturing method for quantum dot display panel

一种显示面板、制作方法的技术,应用在对表面涂布液体的装置、静态指示器、仪器等方向,能够解决喷墨打印设备要求很高、量子点层图形化、不能大规模生产等问题,达到原料制备及制作工艺简单、提升色饱和度与色域、节约成本与制程时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

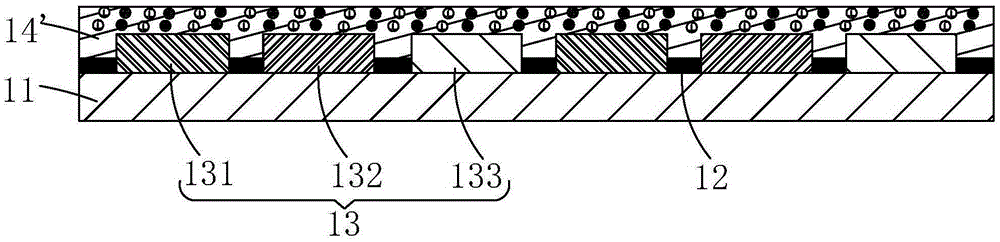

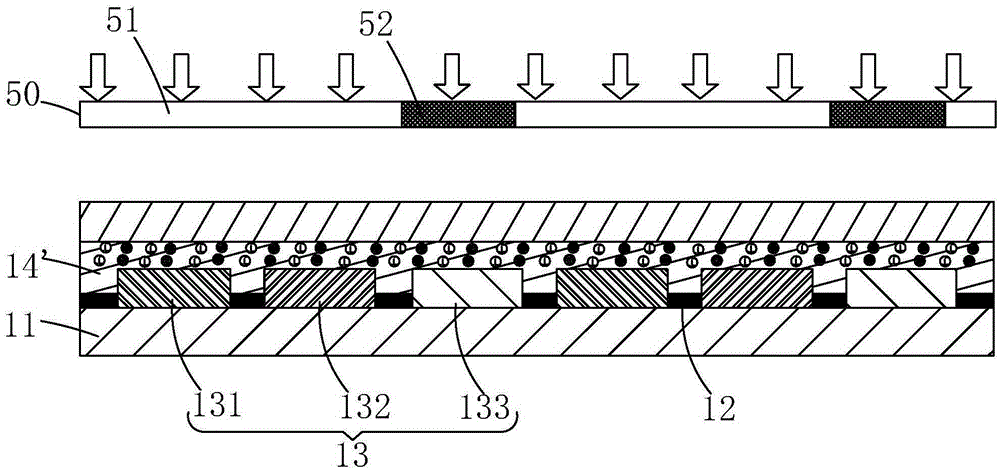

[0038]In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

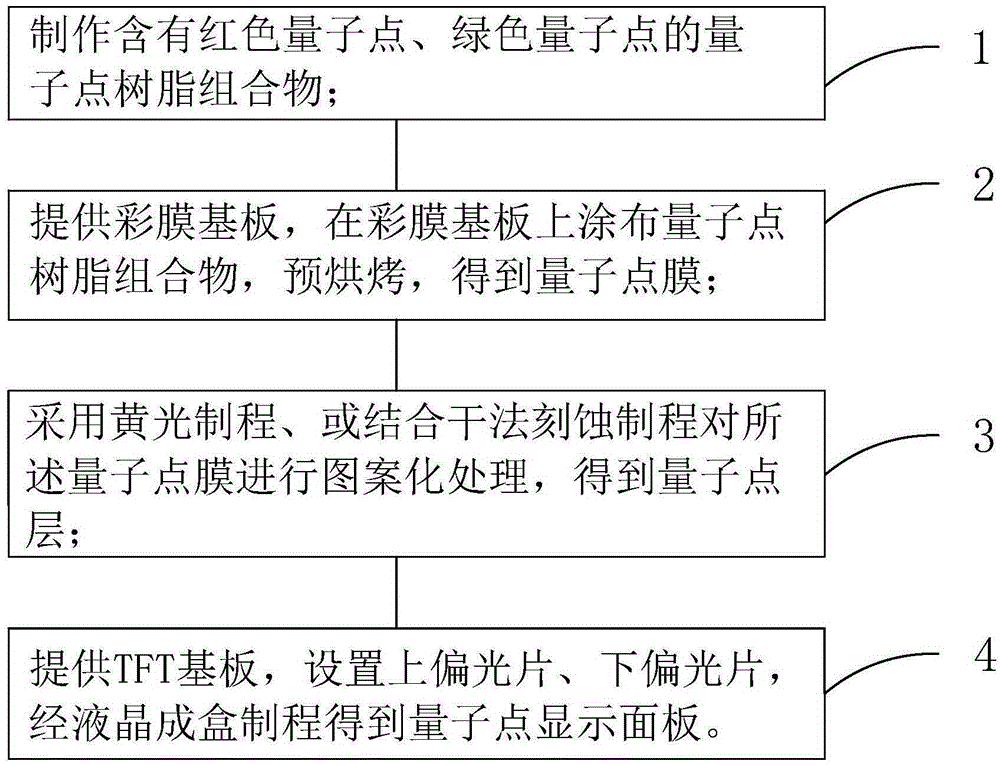

[0039] see figure 1 , the invention provides a method for manufacturing a quantum dot display panel, comprising the steps of:

[0040] Step 1, uniformly mixing the surface-modified red quantum dots, surface-modified green quantum dots, alkali-soluble resin, solvent, dispersant, and additives in a certain proportion to obtain a quantum dot resin composition;

[0041] Specifically, the red quantum dots and green quantum dots in the quantum dot resin composition are II-VI semiconductor materials (such as CdS, CdSe, HgTe, ZnS, ZnSe, ZnTe, HgS), III-V semiconductor materials ( Such as one or more of InP, InAs, GaP, GaAs), IV-VI nano-semiconductor materials, the particle size of the red quantum dots and green quantum dots is 1-10nm.

[0042] Specif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com