Moisture-absorption and sweat-releasing finishing agent for chinlon, and preparation method thereof

A technology of moisture absorption and perspiration and finishing agent, which is applied in fiber treatment, fiber type, textile and paper making, etc. It can solve the problems of unsatisfactory effect, fabric dry and wet rubbing fastness and unsatisfactory hand feeling, etc., so as to improve the hand feeling and response Easy process control and improved durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

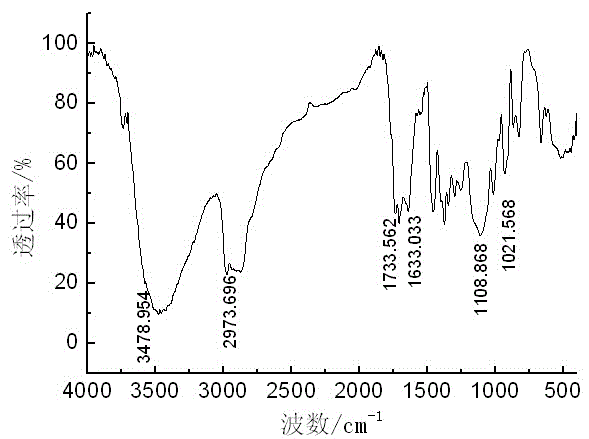

Embodiment 1

[0051] Weigh 0.04 mol polypropylene glycol (molecular weight 1000), and mix the raw materials polypropylene glycol, succinic anhydride, hexamethylene diamine, adipic acid, and 3-aminopropyltrimethoxysilane in a ratio of 1:2:1:1 according to the amount of material. : 1 Weighing is good;

[0052] 1. First, add polypropylene glycol and succinic anhydride into a reaction vessel equipped with an electric stirrer, a thermometer and a reflux device, start stirring, gradually increase the temperature to 120°C, keep the temperature for 5 hours, and obtain Intermediate I;

[0053] 2. Put adipic acid, hexamethylene diamine and triphenyl phosphite accounting for 1% of the total mass of the reaction mixture into a reaction vessel equipped with an electric stirrer, a thermometer and a reflux device, and pass N 2 , Under the condition of constant stirring, heat up to 180℃, keep the temperature and react for 1h, then stop passing N 2 , Vacuum, the degree of vacuum is 0.09atm, the temperature is i...

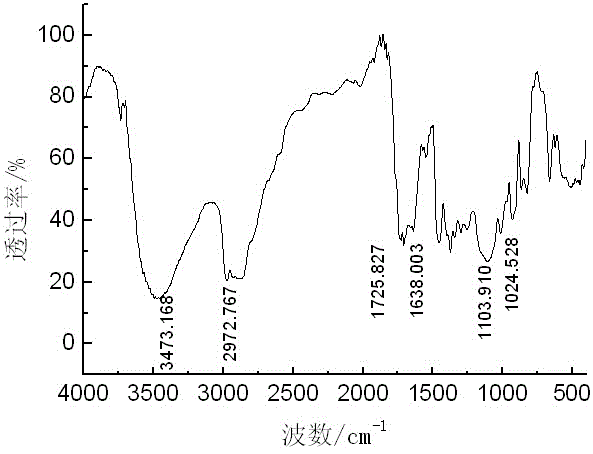

Embodiment 2

[0061] Weigh 0.04 mol polypropylene glycol (molecular weight 1000), and mix the raw materials polypropylene glycol, succinic anhydride, hexamethylene diamine, adipic acid, and 3-aminopropyltrimethoxysilane in a ratio of 1:2:1:1 according to the amount of material. : 1 Weighing is good;

[0062] 1. First, add polypropylene glycol and succinic anhydride into a reaction vessel equipped with an electric stirrer, a thermometer and a reflux device, start stirring, gradually increase the temperature to 130 ℃, keep the temperature for 4 hours, and obtain Intermediate I;

[0063] 2. Put adipic acid, hexamethylene diamine and triphenyl phosphite accounting for 2% of the total mass of the reaction mixture into a reaction vessel equipped with an electric stirrer, a thermometer and a reflux condenser, and pass N 2 , Under the condition of constant stirring, heat up to 180℃, keep the temperature and react for 1h, then stop passing N 2 , Evacuate, the degree of vacuum is 0.09atm, raise the tempe...

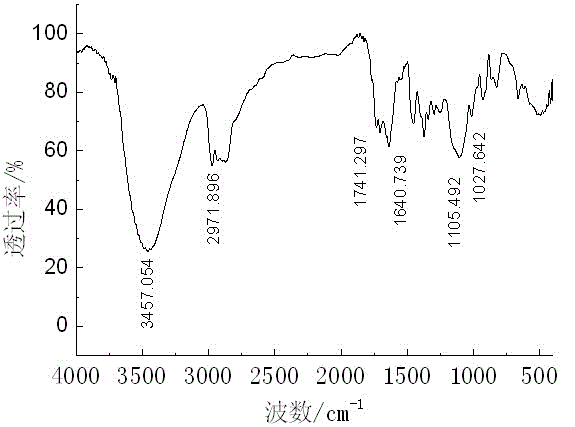

Embodiment 3

[0071] Weigh 0.04 mol polypropylene glycol (molecular weight 1000), and mix the raw materials polypropylene glycol, succinic anhydride, hexamethylene diamine, adipic acid, and 3-aminopropyltrimethoxysilane in a ratio of 1:2:1:1 according to the amount of material. : 1 Weighing is good;

[0072] 1. First, add polypropylene glycol and succinic anhydride into a reaction vessel equipped with an electric stirrer, a thermometer and a reflux device, start stirring, gradually increase the temperature to 140°C, keep the temperature for 3 hours, and obtain the intermediate (I);

[0073] 2. Put adipic acid, hexamethylene diamine and triphenyl phosphite accounting for 3% of the total mass of the reaction mixture into a reaction vessel equipped with an electric stirrer, a thermometer and a reflux condenser, and pass N 2 , Under the condition of constant stirring, heat up to 175 ℃, keep the temperature and react for 1.5h, then stop passing N 2 , Vacuum, the degree of vacuum is 0.09atm, the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com