School uniform fabric production technology

A production process and fabric technology, applied in the field of dyeing process, can solve problems such as difficult to ensure product quality, increase the number of washings, increase the bath ratio of bleaching and dyeing, etc., and achieve the effect of reducing energy consumption, reducing pollution and harm, and the new process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of production technology of school uniform fabric, comprises the following steps:

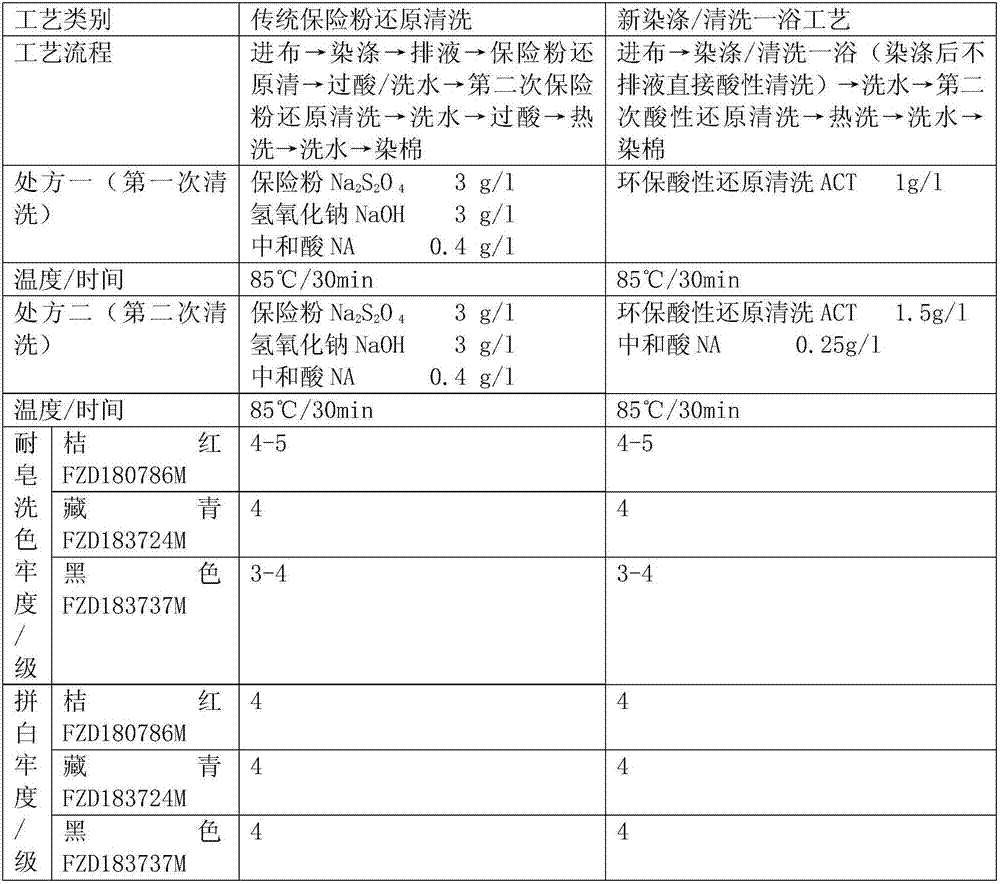

[0036] Pretreatment→dyeing and washing→the first reduction cleaning→drainage→hot washing→washing water→the second reduction cleaning→hot washing→dyeing cotton→fixing color→softening→open-width scouring machine washing→drying→finishing Ordering→testing→complete inspection→packaging / warehousing.

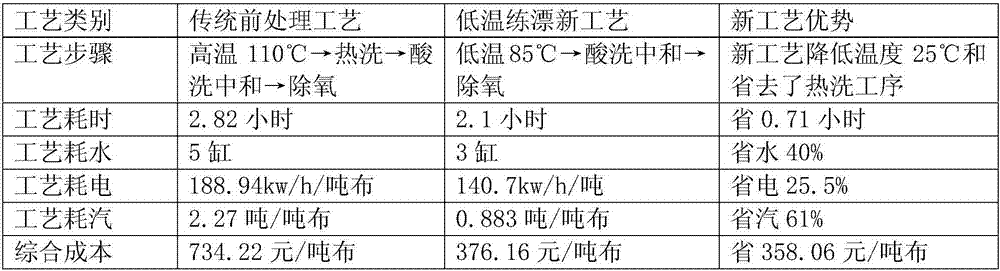

[0037] Specifically, the pretreatment includes: (1), adding water, raising the room temperature to 45°C, adding low-temperature scouring and bleaching agent TF-189, liquid caustic soda, raising the temperature to 65°C at 2.5°C / min, adding hydrogen peroxide, and then heating at 3.5°C / min Min to raise the temperature to 90°C, keep it warm for 25min, then cool down to 85°C at 1.5°C / min, and drain water; (2), add water at 55°C, add neutralizing acid NA, wash for 5min, and drain water; (3), at 45°C In the water, add deoxygenase, deoxygenate for 20 minutes, and release water. Further, the dosag...

Embodiment 2

[0046] A kind of production technology of school uniform fabric, comprises the following steps:

[0047] Pretreatment→dyeing and washing→the first reduction cleaning→drainage→hot washing→washing water→the second reduction cleaning→hot washing→dyeing cotton→fixing color→softening (hydrophilic soft oil)→open width washing machine washing Water→drying→settling→testing→scanning→packing / warehousing.

[0048]Specifically, the pretreatment includes: (1), adding water, raising the room temperature to 55°C, adding low-temperature scouring and bleaching agent TF-189, liquid caustic soda, raising the temperature to 75°C at 3.5°C / min, adding hydrogen peroxide, and then adding hydrogen peroxide at 2.5°C / min Min to heat up to 80°C, keep warm for 35min, then cool down to 75°C at 2.5°C / min, and release water; (2), add water at 45°C, add neutralizing acid NA, wash for 15 minutes, and release water; (3), at 55°C In the water, add deoxygenase, deoxygenate for 10 minutes, and release the water. ...

Embodiment 3

[0057] A kind of production technology of school uniform fabric, comprises the following steps:

[0058] Pretreatment→dyeing and washing→the first reduction cleaning→drainage→hot washing→washing water→the second reduction cleaning→hot washing→dyeing cotton→fixing color→softening (hydrophilic soft oil)→open width washing machine washing Water→drying→settling→testing→scanning→packing / warehousing.

[0059] Specifically, the pretreatment includes: (1), adding water, raising the room temperature to 40°C, adding low-temperature scouring and bleaching agent TF-189, liquid caustic soda, raising the temperature to 70°C at 2°C / min, adding hydrogen peroxide, and then heating at 35°C / min. Min to raise the temperature to 85°C, keep it warm for 30min, then cool down to 80°C at 2°C / min, and release water; (2), add 50°C water, add neutralizing acid NA, wash for 10min, and release water; (3), add 50°C Add deoxygenase to the water, deoxygenate for 15 minutes, release water, further low-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com