Reactive dyes dyeing method of beam shaped superfine fiber PU synthetic leather

A technology of ultra-fine fiber and reactive dyes, applied in the field of dyeing, can solve the problems of poor color fastness, large specific surface area, poor color rendering, etc., and achieve an environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

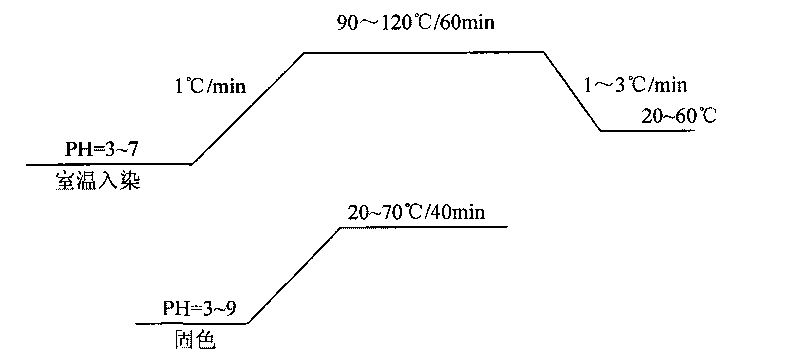

[0019] Use reactive dye A for wool at 2%-5% (owf), bath ratio 1:15-30, pH 3-7, heat up from room temperature to 90-120°C at a rate of 1°C / min, keep warm for 10 or 20 or 30 or 40 Or 50 or 60 or 70 minutes, 1 ~ 3 ° C / min to 20-60 ° C, then adjust the pH3 ~ 9 at 20-70 ° C for 20 ~ 60 minutes to fix the color, dyeing bundles of microfiber PU synthetic leather.

Embodiment 2

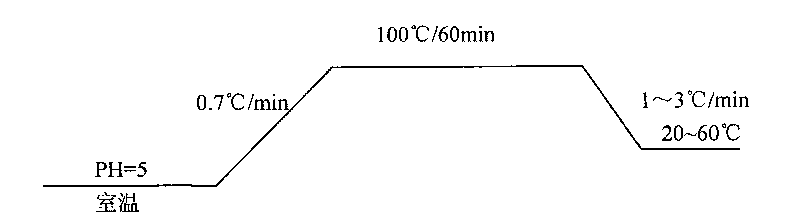

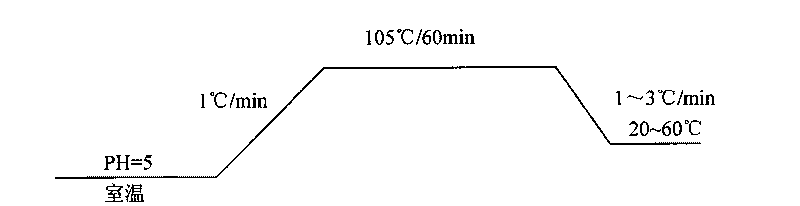

[0021] Use reactive dye A for wool at 2%-5% (owf), bath ratio 1:15-30, pH 3-7, heat up from room temperature to 90-120°C at a rate of 1°C / min, keep warm for 60min, and heat at 1-3°C / min down to 20 ~ 60 ℃, dyeing bundles of microfiber PU synthetic leather.

Embodiment 3

[0023] Use reactive dye A for wool at 2%-5% (owf), bath ratio 1:15-30, pH value is 3-7 respectively, heat up from room temperature to 90-120°C at a speed of 1°C / min, keep warm for 60min, and 1-3°C / min to 20-60°C, then adjust the pH to 3-9 at 20-70°C for 20, 30, 40, 50, and 60 minutes of color fixation, and dye bundle-shaped microfiber PU synthetic leather.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com