Dyeing and finishing method of CVC (chief value of cotton) dyster fabric

A fabric and dye technology, applied in the field of dyeing and finishing of CVC Dansberg fabrics, can solve the problems of complex dyeing and finishing process, difficult dyeing uniformity, poor wearing performance, etc. Soft-touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

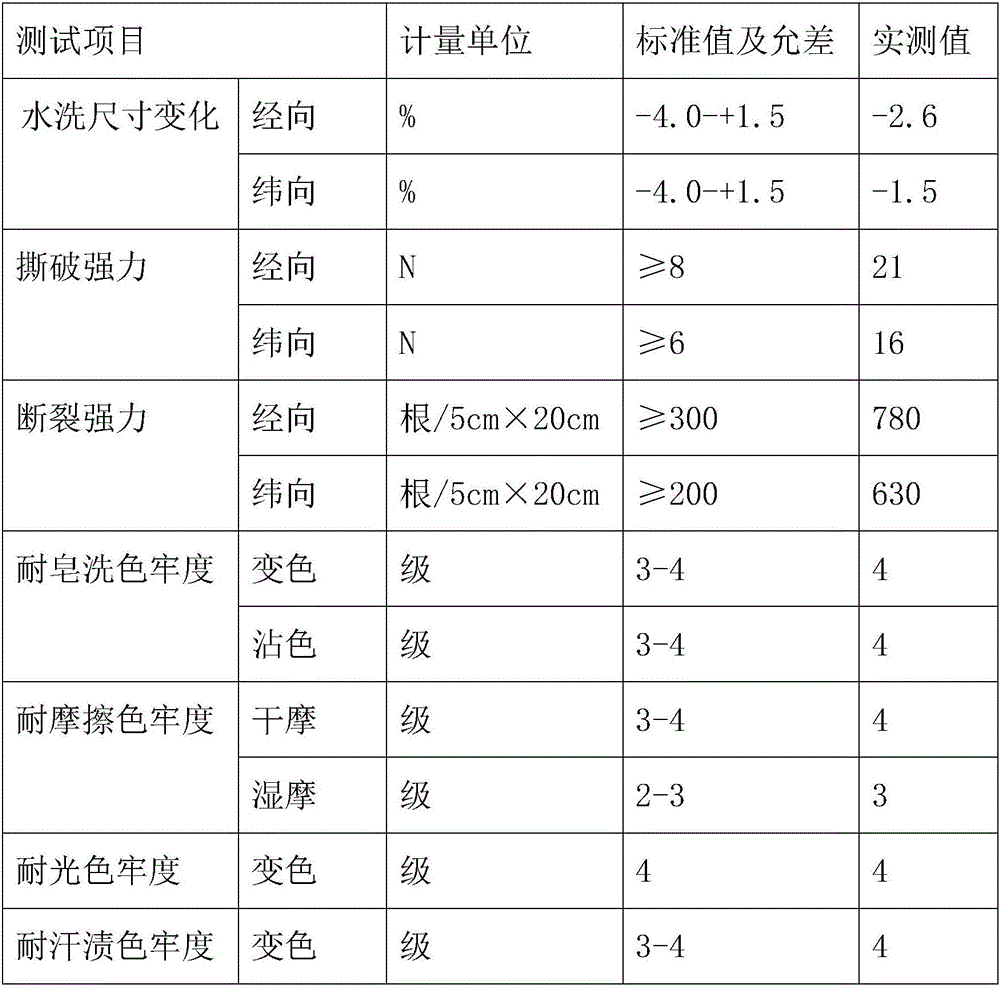

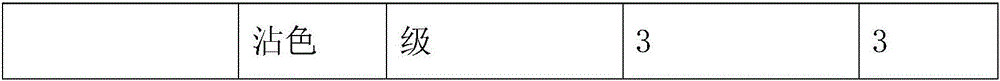

Examples

Embodiment 1

[0030] A dyeing and finishing method of CVC Dansbury fabric, comprising the steps of:

[0031] S1, pretreatment, its concrete operation comprises:

[0032] S11. Singeing. Singeing is performed by a double-jet burner singeing machine. The flame injection speed is 7m / s, the vehicle speed is 95m / min, two positive and one reverse, three burners, and the singeing grade is 3-4;

[0033] S12. Cold stacking, normal temperature padding and rolling working fluid, two dipping and two rolling, the excess rate is 60%, the speed is 40m / min, the working fluid includes: caustic soda 35g / L, hydrogen peroxide 5g / L, penetrant 1g / L, boiling Refining agent 10g / L, chelating dispersant 1g / L, stacked at room temperature for 20h at a speed of 6r / min after coiling;

[0034] S13. Desizing, hot washing at 45°C for 10 minutes, placing in a desizing solution at 70°C for 60 minutes, the desizing solution includes: desizing enzyme OD-355 3g / L, NaCl 5g / L, penetrant JFC 1g / L, Chelating agent TH305 1g / L, adju...

Embodiment 2

[0044] A dyeing and finishing method of CVC Dansbury fabric, comprising the steps of:

[0045] S1, pretreatment, its concrete operation comprises:

[0046] S11. Singeing. Singeing is performed by a double-jet burner singeing machine. The flame injection speed is 15m / s, the vehicle speed is 85m / min, two positive and one reverse, three burners, and the singeing grade is 3-4;

[0047] S12. Cold stacking, normal temperature padding and rolling working fluid, two dipping and two rolling, the excess rate is 90%, the speed is 30m / min, the working fluid includes: caustic soda 40g / L, hydrogen peroxide 1g / L, penetrating agent 5g / L, boiling Refining agent 8g / L, chelating dispersant 5g / L, stacked at room temperature for 25h at a speed of 5r / min after coiling;

[0048] S13. Desizing, hot washing at 55°C for 5 minutes, placing in a desizing solution at 80°C for 30 minutes, the desizing solution includes: desizing enzyme OD-355 4g / L, NaCl 2g / L, penetrant JFC 2g / L, Chelating agent TH305 0.5...

Embodiment 3

[0059] A dyeing and finishing method of CVC Dansbury fabric, comprising the steps of:

[0060] S1, pretreatment, its concrete operation comprises:

[0061] S11. Singeing. Singeing is performed by a double-jet burner singeing machine. The flame injection speed is 11m / s, the vehicle speed is 90m / min, two positive and one reverse, three burners, and the singeing grade is 3-4;

[0062] S12. Cold stacking, normal temperature padding and rolling working fluid, two dipping and two rolling, the excess rate is 75%, the speed is 35m / min, the working fluid includes: caustic soda 37g / L, hydrogen peroxide 3g / L, penetrant 3g / L, boiling Refining agent 9g / L, chelating dispersant 3g / L, stacked at room temperature for 22h at a speed of 5.5r / min after coiling;

[0063] S13. Desizing, hot wash at 50°C for 7 minutes, place in a desizing solution at 75°C for 45 minutes, and the desizing solution includes: desizing enzyme OD-355 3.5g / L, NaCl 3.5g / L, penetrant JFC 1.5g / L, chelating agent TH305 0.7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com