Production process of clean appearance pure cotton and cotton blended knitted fabric

A knitted fabric and production process technology, applied in the field of textile technology, can solve the problems of high requirements for equipment and processing technology, large shrinkage, difficulty in ranking among high-end fabrics, etc., and achieve the improvement of fabric appearance and comprehensive quality, resilience and stiffness. The effect of improving, improving the grade and adding value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Choose 50D / 36F POLYESTER SEMI-DULL DTY S TWIST+30S / 1COMPACT COTTON(REGULAR)+10S / 1 combed cotton, left slanted double garment;

[0034] 1) singeing: the above-mentioned left oblique double-position garment knitted fabric is subjected to singeing treatment through an open-width singeing machine, with double burners on the cloth surface and single burner on the bottom of the cloth, and the machine speed is 50m / min;

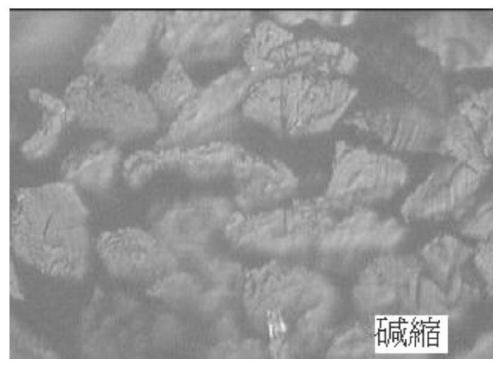

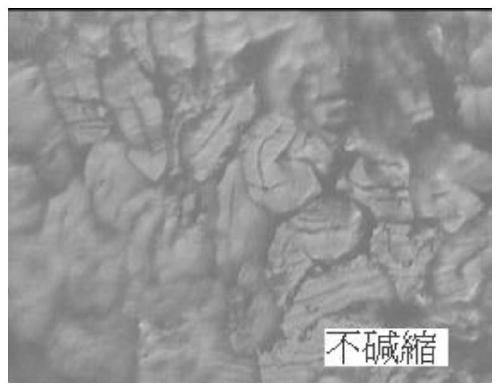

[0035] 2) Alkali shrinkage: the cloth after singeing treatment is subjected to alkali shrinkage treatment through an alkali shrinkage machine, caustic soda concentration: 18°Bé; temperature: 20°C, machine speed: 15m / min; alkali shrinkage penetrant: 17g / L; Cloth overfeed: 4%; cloth overfeed: -2%, roll up to the cloth frame, and the liquid content is 95%;

[0036] 3) Stacking: The cloth on the cloth rack is sealed and packaged, and a motor is installed on the shaft end of the cloth rack to rotate and stack, the time is 5 hours, and the rotation speed is 10 rpm; ...

Embodiment 2

[0044] Choose 75D / 72F POLYESTER SEMI-DULL DTY S TWIST+40S / 2 combed cotton+20S / 2 combed cotton, left slanted double garment.

[0045] 1) singeing: the above-mentioned left-slanted double-position garment knitted fabric is subjected to singeing treatment through an open-width singeing machine, with a double burner on the cloth surface and a single burner at the bottom of the cloth, and the machine speed is 60m / min;

[0046] 2) Alkali shrinkage: the cloth after singeing treatment is subjected to alkali shrinkage treatment through alkali shrinkage machine, caustic soda concentration: 18°Bé; temperature: 18°C, machine speed: 15m / min; alkali shrinkage penetrant: 15g / L; Cloth overfeed: 3.8%; cloth overfeed: -2%, roll up to the cloth frame, and the liquid content is 100%.

[0047] 3) Stacking: The cloth on the cloth rack is sealed and packaged, and a motor is installed on the shaft end of the cloth rack to rotate and stack, the time is 6 hours, and the rotation speed is 10 rpm;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com