Production process of irregular cylindrical wool felt

A production process, the technology of wool felt, applied in the field of cylindrical special-shaped wool felt production process, can solve the problems of low production efficiency, difficult control of product quality, inability to apply large-scale industrial production, etc., and achieve good controllability and good surface effect, high-intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

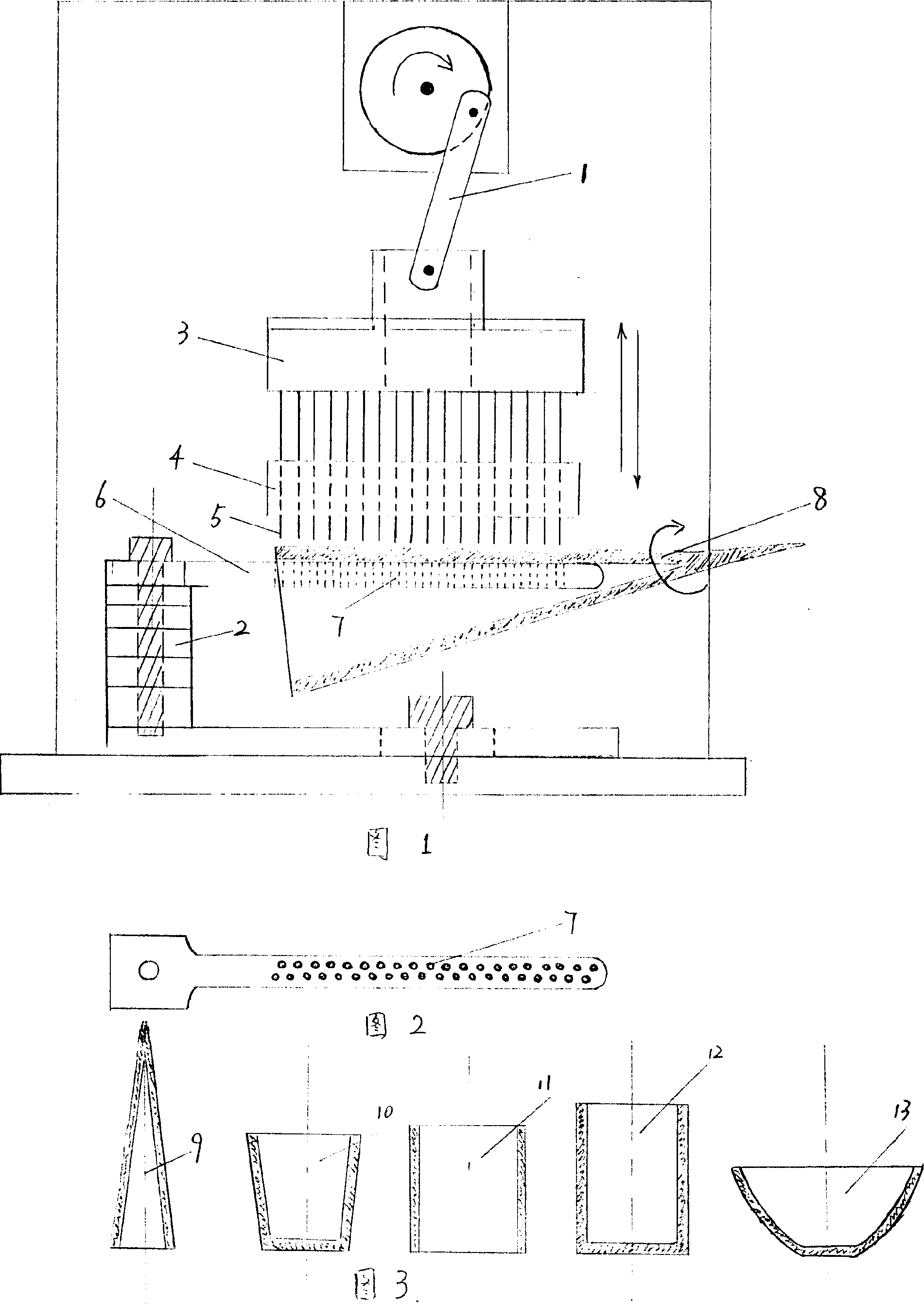

[0011] As shown in Figure 3, cylindrical special-shaped wool felt usually has a cylindrical conical shape (9), a cylindrical flat-bottomed cone shape (10), a cylindrical circular shape (11), a cylindrical cylindrical shape (12), and a cylindrical bowl shape. (13) etc. 5 kinds. We spread the carded wool nets evenly on these tubular molds to make tubular shaped wool nets. These tubular shaped wool felt nets have a common feature, that is, they have a multi-functional The cylindrical inner cavity inserted into the rod-shaped acupuncture platform (6) of the small-sized acupuncture machine, then these cylindrical special-shaped wool mesh sleeves can be placed on the rod-shaped acupuncture platform (6), through the cam linkage of the acupuncture machine The mechanism (1) drives the needle plate (3) to move back and forth vertically, and the needle (5) can pierce through the stripper plate (4) to repeatedly puncture the cylindrical special-shaped wool net (8). There are needle holes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com