Home textile fabric and blending method thereof

A fabric and home textile technology, applied in the field of home textile fabrics and their blends, can solve the problems of unconsidered effects, difficult production, and not easy to bend, and achieve the effects of unique silk gloss, reduced manufacturing costs, and soft touch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] As shown in the figure, a home textile fabric is blended with Lyocell fiber, Modal fiber and cotton fiber. The warp and weft yarns are 80 counts, the warp density is 182 threads / inch, and the weft density is 120 threads / inch. Inch, the fabric weave is satin weave.

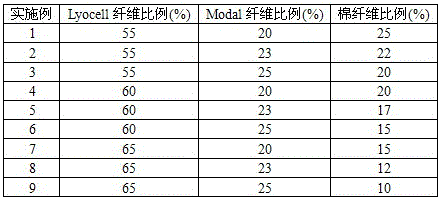

[0037] The mass ratio of the three raw materials of Lyocell fiber, Modal fiber and cotton fiber to the total raw materials is 55-65% of Lyocell fiber, 20-25% of Modal fiber, and the rest is cotton fiber.

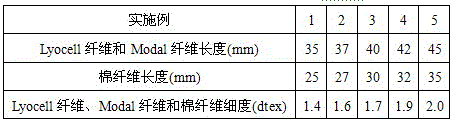

[0038] The length of the Lyocell fiber and the Modal fiber is 35-45mm, the length of the cotton fiber is 25-35mm, and the fineness of the three kinds of fibers is 1.4-2.0dtex.

[0039] The blending step of described home textile fabric is:

[0040](1) Opening and wool process: first open the Modal fiber separately twice, then mix the Modal fiber and cotton fiber evenly and open once, add 0.3-0.7% of wool oil and 0.8-1.2% of antistatic agent at the same time %, the moisture regain is controlled at 17-23%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com