Production process of four-side elastic fabric

A production process and four-way elastic technology, applied in the field of textiles, can solve the problems of easy static electricity, poor color fastness to perspiration, insufficient depth, etc., and achieve the effects of avoiding dyeing, good light fastness, and reducing stress accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

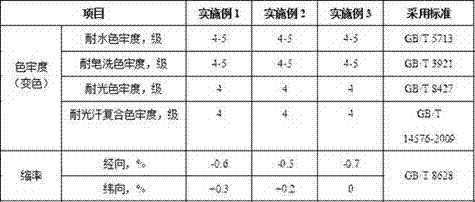

Examples

Embodiment 1

[0028] A production process of four-way stretch fabric, comprising the following steps:

[0029] S1: Yarn matching: Nylon spandex twisted core-spun yarn is used in the warp direction, and high wet modulus fiber-wrapped spandex yarn is used in the weft direction; the specification of the nylon-wrapped spandex yarn is 70D wrapped 40D, and the high-humid modulus fiber wrapped spandex yarn The specification is 40S package 40D;

[0030] S2: Weaving: Use a 210cm wide air-jet loom or rapier loom to weave the yarns in step S1 into nylon yarns that appear on the front of the fabric, and high-moisture modulus fiber yarns that appear on the shuttle on the reverse side of the fabric woven fabric;

[0031] S3: Pre-treatment: use the open-width continuous loose pre-treatment process to pre-treat the gray cloth;

[0032] S4: Mechanical softening finishing: AIRO-1000 type loose mechanical softening finishing machine is adopted, the processing temperature is 90°C, the running speed is 200m / m...

Embodiment 2

[0040] A production process of four-way stretch fabric, comprising the following steps:

[0041] S1: Yarn matching: Nylon spandex twisted core-spun yarn is used in the warp direction, and high wet modulus fiber-wrapped spandex yarn is used in the weft direction; the specifications of the nylon-wrapped spandex yarn are 40D and 20D, and the specifications of the high-humidity fiber-wrapped spandex yarn 32S package 40D;

[0042] S2: Weaving: Use a 230cm wide air-jet loom or rapier loom to weave the yarns in step S1 into nylon yarns that appear on the front of the fabric, and high-moisture modulus fiber yarns that appear on the shuttle on the reverse side of the fabric woven fabric;

[0043] S3: Pre-treatment: use the open-width continuous loose pre-treatment process to pre-treat the gray cloth;

[0044] S4: Mechanical softening finishing: AIRO-1000 type loose mechanical softening finishing machine is adopted, the processing temperature is 100°C, the running speed is 250m / min, t...

Embodiment 3

[0052] A production process of four-way stretch fabric, comprising the following steps:

[0053] S1: Yarn matching: Nylon spandex twisted core-spun yarn is used in the warp direction, and high wet modulus fiber-wrapped spandex yarn is used in the weft direction; the specification of the nylon-wrapped spandex yarn is 70D wrapped 40D, and the high-humid modulus fiber wrapped spandex yarn Gauge 21S package 40D;

[0054] S2: Weaving: Use a 220cm wide air-jet loom or rapier loom to weave the yarns in step S1 into nylon yarns that appear on the front of the fabric, and high-moisture modulus fiber yarns that appear on the shuttle on the reverse side of the fabric woven fabric;

[0055] S3: Pre-treatment: use the open-width continuous loose pre-treatment process to pre-treat the gray cloth;

[0056] S4: Mechanical softening finishing: AIRO-1000 type loose mechanical softening finishing machine is adopted, the processing temperature is 95°C, the running speed is 230m / min, the finishi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com