Method for separating MEOH-DMC (methanol-dimethyl carbonate) through vapor permeation

A technology of MEOH-DMC and steam, which is applied in the direction of semipermeable membrane separation, chemical instruments and methods, separation/purification of hydroxyl compounds, etc. Short service life and other problems, to achieve the effect of reducing cooling operation costs, reducing condensation operation costs, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

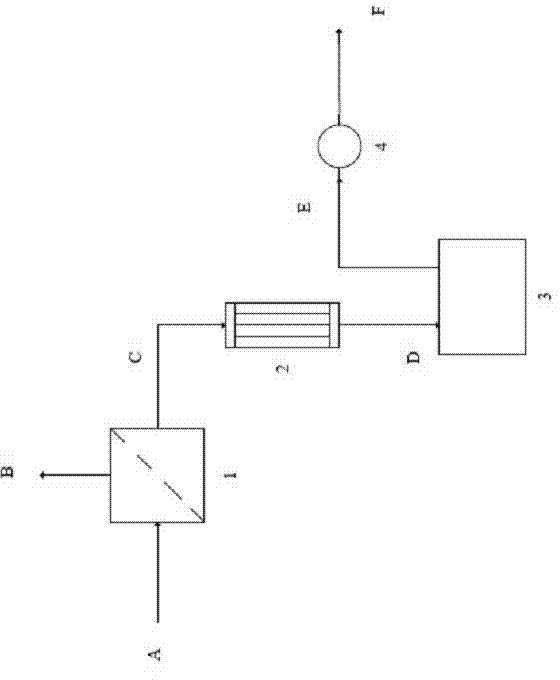

Method used

Image

Examples

Embodiment 1

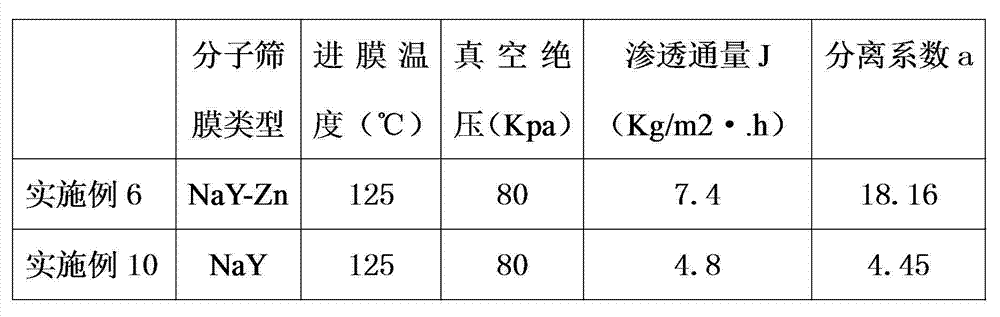

[0033] Example 1 Preparation of NaY-Zn molecular sieve membrane

[0034] (1) with Na 2 O n SiO 2 , Al(OH) 3 , Zn(OH) 2 As the raw material, prepare the raw material liquid SiO 2 - Na 2 O-Al 2 O 3 -ZnO -H 2 O system, the molar ratio of each component is: Na 2 O: Al 2 O 3 : SiO 2 :ZnO:H 2 O=16:1:15:1:360. According to the above molar ratio as the formula, calculate the required amount of silicon source, aluminum source, zinc source and water, mix the silicon solution, aluminum solution and zinc solution vigorously to form a gel, then pour it into the reactor of polymer material, put the The raw gel solution was aged at room temperature for 5 hours.

[0035] (2) Porous a-Al coated with NaY-Zn molecular sieve seeds 2 O 3 The supporting membrane tube is fixed in the synthesis reaction kettle, the raw gel solution prepared in step (1) is poured into the reaction kettle, and after sealing, a hydrothermal reaction is carried out at 100 ° C for 2 hours; the obtained m...

Embodiment 2

[0038] Example 2 Preparation of NaY-Zn molecular sieve membrane

[0039] The steps are the same as those in Example 1, but the molar ratios of the components are different.

[0040] In this embodiment, the molar ratio of each component is: Na 2 O: Al 2 O 3 : SiO 2 : ZnO : H 2 O=18:1:19:3:700. The steps are:

[0041] (1) with Na 2 O n SiO 2 , Al(OH) 3 , Zn(OH) 2 As the raw material, prepare the raw material liquid SiO 2 - Na 2 O-Al 2 O 3 -ZnO -H 2 O system, the molar ratio of each component is: Na 2 O: Al 2 O 3 : SiO 2 :ZnO:H 2 O=18:1:19:3:700. According to the above molar ratio as the formula, calculate the required amount of silicon source, aluminum source, zinc source and water, mix the silicon solution, aluminum solution and zinc solution vigorously to form a gel, then pour it into the reactor of polymer material, put the The raw gel solution was aged at room temperature for 14 hours.

[0042] (2) Porous a-Al coated with NaY-Zn molecular sieve see...

Embodiment 3

[0045] Example 3 Preparation of NaY-Zn molecular sieve membrane

[0046] In this embodiment, the molar ratio of each component is: Na 2 O: Al 2 O 3 : SiO 2 :ZnO:H 2 O=23:1:24:5:900, the steps are:

[0047] (1) with Na 2 O n SiO 2 , Al(OH) 3 , Zn(OH) 2 As the raw material, prepare the raw material liquid SiO 2 - Na 2 O-Al 2 O 3 -ZnO -H 2 O system, the molar ratio of each component is: Na 2 O: Al 2 O 3 : SiO 2 :ZnO:H 2 O=23:1:24:5:900. According to the above molar ratio as the formula, calculate the required amount of silicon source, aluminum source, zinc source and water, mix the silicon solution, aluminum solution and zinc solution vigorously to form a gel, then pour it into the reactor of polymer material, put the The raw gel solution was aged at room temperature for 18 hours.

[0048] (2) Porous a-Al coated with NaY-Zn molecular sieve seeds 2 O 3 The supporting membrane tube is fixed in the synthesis reactor, the raw gel solution prepared in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com